PDF Publication Title:

Text from PDF Page: 001

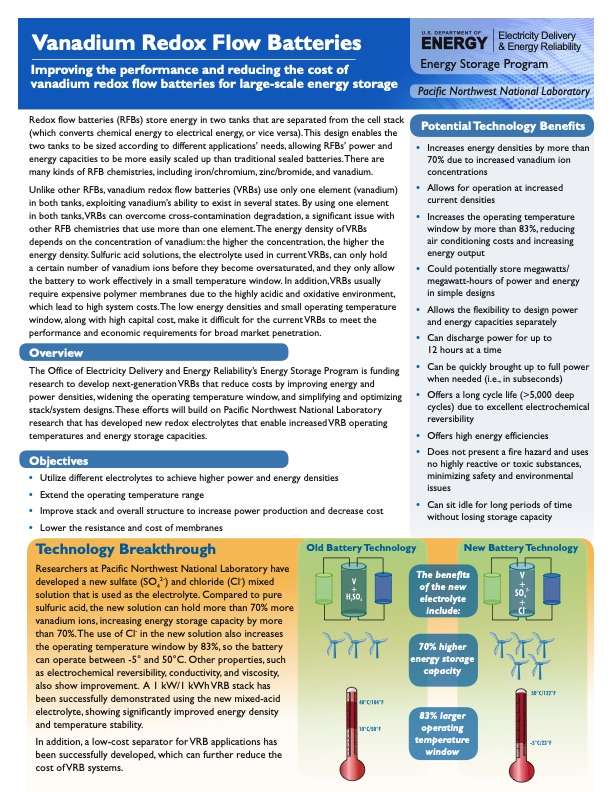

Vanadium Redox Flow Batteries Improving the performance and reducing the cost of vanadium redox flow batteries for large-scale energy storage Redox flow batteries (RFBs) store energy in two tanks that are separated from the cell stack (which converts chemical energy to electrical energy, or vice versa).This design enables the two tanks to be sized according to different applications’ needs, allowing RFBs’ power and energy capacities to be more easily scaled up than traditional sealed batteries.There are many kinds of RFB chemistries, including iron/chromium, zinc/bromide, and vanadium. Unlike other RFBs, vanadium redox flow batteries (VRBs) use only one element (vanadium) in both tanks, exploiting vanadium’s ability to exist in several states. By using one element in both tanks,VRBs can overcome cross-contamination degradation, a significant issue with other RFB chemistries that use more than one element.The energy density ofVRBs depends on the concentration of vanadium: the higher the concentration, the higher the energy density. Sulfuric acid solutions, the electrolyte used in current VRBs, can only hold a certain number of vanadium ions before they become oversaturated, and they only allow the battery to work effectively in a small temperature window. In addition,VRBs usually require expensive polymer membranes due to the highly acidic and oxidative environment, which lead to high system costs.The low energy densities and small operating temperature window, along with high capital cost, make it difficult for the current VRBs to meet the performance and economic requirements for broad market penetration. Overview The Office of Electricity Delivery and Energy Reliability’s Energy Storage Program is funding research to develop next-generation VRBs that reduce costs by improving energy and power densities, widening the operating temperature window, and simplifying and optimizing stack/system designs.These efforts will build on Pacific Northwest National Laboratory research that has developed new redox electrolytes that enable increased VRB operating temperatures and energy storage capacities. Objectives Electricity Delivery & Energy Reliability Energy Storage Program Pacific Northwest National Laboratory Potential Technology Benefits • Increases energy densities by more than 70% due to increased vanadium ion concentrations • Allows for operation at increased current densities • Increases the operating temperature window by more than 83%, reducing air conditioning costs and increasing energy output • Could potentially store megawatts/ megawatt-hours of power and energy in simple designs • Allows the flexibility to design power and energy capacities separately • Can discharge power for up to 12 hours at a time • Can be quickly brought up to full power when needed (i.e., in subseconds) • Offers a long cycle life (>5,000 deep cycles) due to excellent electrochemical reversibility • Offers high energy efficiencies • Does not present a fire hazard and uses no highly reactive or toxic substances, minimizing safety and environmental issues • Can sit idle for long periods of time without losing storage capacity • • • • Utilize different electrolytes to achieve higher power and energy densities Extend the operating temperature range Improve stack and overall structure to increase power production and decrease cost Lower the resistance and cost of membranes Technology Breakthrough Researchers at Pacific Northwest National Laboratory have developed a new sulfate (SO42-) and chloride (Cl-) mixed solution that is used as the electrolyte. Compared to pure sulfuric acid, the new solution can hold more than 70% more vanadium ions, increasing energy storage capacity by more than 70%. The use of Cl- in the new solution also increases the operating temperature window by 83%, so the battery can operate between -5° and 50°C. Other properties, such as electrochemical reversibility, conductivity, and viscosity, also show improvement. A 1 kW/1 kWh VRB stack has been successfully demonstrated using the new mixed-acid electrolyte, showing significantly improved energy density and temperature stability. In addition, a low-cost separator for VRB applications has been successfully developed, which can further reduce the cost of VRB systems. Old Battery Technology New Battery Technology The benefits of the new electrolyte include: 70% higher energy storage capacity 83% larger operating temperature windowPDF Image | Vanadium Redox Flow Batteries USDOE

PDF Search Title:

Vanadium Redox Flow Batteries USDOEOriginal File Name Searched:

081_Vanadium_Redox_Battieries.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Salt water flow battery technology with low cost and great energy density that can be used for power storage and thermal storage. Let us de-risk your production using our license. Our aqueous flow battery is less cost than Tesla Megapack and available faster. Redox flow battery. No membrane needed like with Vanadium, or Bromine. Salgenx flow battery

| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |