PDF Publication Title:

Text from PDF Page: 003

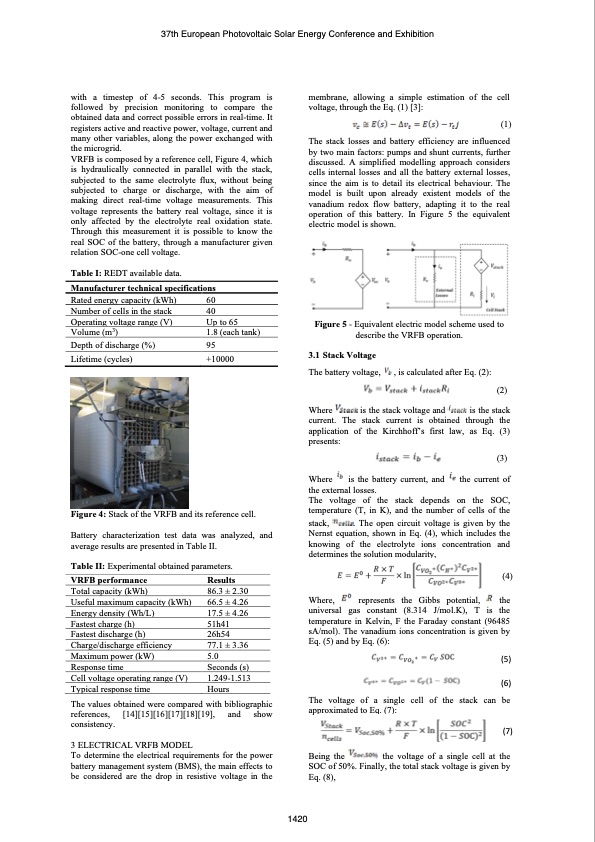

37th European Photovoltaic Solar Energy Conference and Exhibition with a timestep of 4-5 seconds. This program is followed by precision monitoring to compare the obtained data and correct possible errors in real-time. It registers active and reactive power, voltage, current and many other variables, along the power exchanged with the microgrid. VRFB is composed by a reference cell, Figure 4, which is hydraulically connected in parallel with the stack, subjected to the same electrolyte flux, without being subjected to charge or discharge, with the aim of making direct real-time voltage measurements. This voltage represents the battery real voltage, since it is only affected by the electrolyte real oxidation state. Through this measurement it is possible to know the real SOC of the battery, through a manufacturer given relation SOC-one cell voltage. Table I: REDT available data. Manufacturer technical specifications membrane, allowing a simple estimation of the cell voltage, through the Eq. (1) [3]: (1) The stack losses and battery efficiency are influenced by two main factors: pumps and shunt currents, further discussed. A simplified modelling approach considers cells internal losses and all the battery external losses, since the aim is to detail its electrical behaviour. The model is built upon already existent models of the vanadium redox flow battery, adapting it to the real operation of this battery. In Figure 5 the equivalent electric model is shown. Figure 5 - Equivalent electric model scheme used to describe the VRFB operation. 3.1 Stack Voltage The battery voltage, , is calculated after Eq. (2): (2) Where is the stack voltage and is the stack current. The stack current is obtained through the application of the Kirchhoff’s first law, as Eq. (3) presents: (3) Where is the battery current, and the current of the external losses. The voltage of the stack depends on the SOC, temperature (T, in K), and the number of cells of the stack, . The open circuit voltage is given by the Nernst equation, shown in Eq. (4), which includes the knowing of the electrolyte ions concentration and determines the solution modularity, (4) Where, represents the Gibbs potential, the universal gas constant (8.314 J/mol.K), T is the temperature in Kelvin, F the Faraday constant (96485 sA/mol). The vanadium ions concentration is given by Eq. (5) and by Eq. (6): (5) (6) The voltage of a single cell of the stack can be approximated to Eq. (7): (7) Being the the voltage of a single cell at the SOC of 50%. Finally, the total stack voltage is given by Eq. (8), Rated energy capacity (kWh) Number of cells in the stack Operating voltage range (V) Volume (m3) Depth of discharge (%) Lifetime (cycles) 60 40 Upto65 1.8 (each tank) 95 +10000 Figure 4: Stack of the VRFB and its reference cell. Battery characterization test data was analyzed, and average results are presented in Table II. Table II: Experimental obtained parameters. VRFB performance Total capacity (kWh) Useful maximum capacity (kWh) Energy density (Wh/L) Fastest charge (h) Fastest discharge (h) Charge/discharge efficiency Maximum power (kW) Response time Cell voltage operating range (V) Typical response time Results 86.3 ± 2.30 66.5 ± 4.26 17.5 ± 4.26 51h41 26h54 77.1 ± 3.36 5.0 Seconds (s) 1.249-1.513 Hours The values obtained were compared with bibliographic references, [14][15][16][17][18][19], and show consistency. 3 ELECTRICAL VRFB MODEL To determine the electrical requirements for the power battery management system (BMS), the main effects to be considered are the drop in resistive voltage in the 1420PDF Image | VANADIUM REDOX FLOW BATTERY MODELLING

PDF Search Title:

VANADIUM REDOX FLOW BATTERY MODELLINGOriginal File Name Searched:

Vanadium-Redox-Flow-Battery-Modelling.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Salt water flow battery technology with low cost and great energy density that can be used for power storage and thermal storage. Let us de-risk your production using our license. Our aqueous flow battery is less cost than Tesla Megapack and available faster. Redox flow battery. No membrane needed like with Vanadium, or Bromine. Salgenx flow battery

| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |