PDF Publication Title:

Text from PDF Page: 008

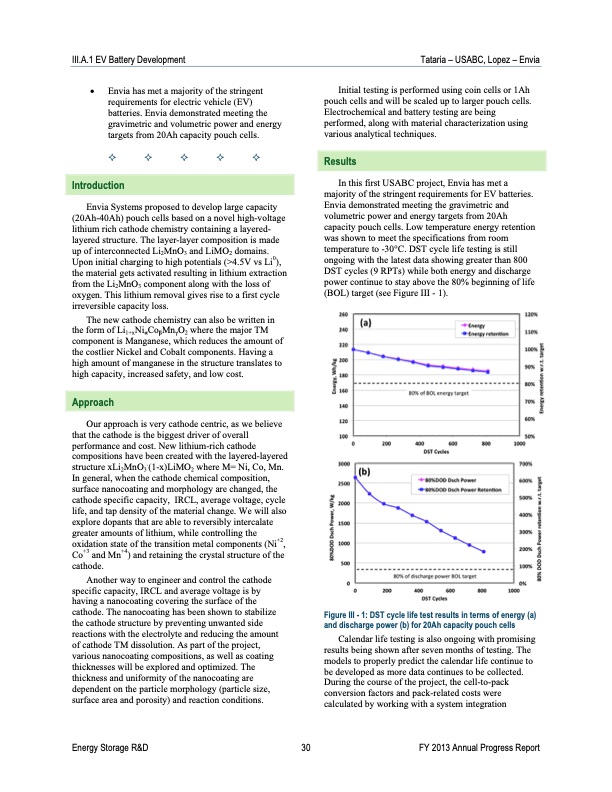

III.A.1 EV Battery Development Tataria – USABC, Lopez – Envia Envia has met a majority of the stringent requirements for electric vehicle (EV) batteries. Envia demonstrated meeting the gravimetric and volumetric power and energy targets from 20Ah capacity pouch cells. Introduction Envia Systems proposed to develop large capacity (20Ah-40Ah) pouch cells based on a novel high-voltage lithium rich cathode chemistry containing a layered- layered structure. The layer-layer composition is made up of interconnected Li2MnO3 and LiMO2 domains. Upon initial charging to high potentials (>4.5V vs Li0), the material gets activated resulting in lithium extraction from the Li2MnO3 component along with the loss of oxygen. This lithium removal gives rise to a first cycle irreversible capacity loss. The new cathode chemistry can also be written in the form of Li1+xNiαCoβMnγO2 where the major TM component is Manganese, which reduces the amount of the costlier Nickel and Cobalt components. Having a high amount of manganese in the structure translates to high capacity, increased safety, and low cost. Approach Our approach is very cathode centric, as we believe that the cathode is the biggest driver of overall performance and cost. New lithium-rich cathode compositions have been created with the layered-layered structure xLi2MnO3.(1-x)LiMO2 where M= Ni, Co, Mn. In general, when the cathode chemical composition, surface nanocoating and morphology are changed, the cathode specific capacity, IRCL, average voltage, cycle life, and tap density of the material change. We will also explore dopants that are able to reversibly intercalate greater amounts of lithium, while controlling the oxidation state of the transition metal components (Ni+2, Co+3 and Mn+4) and retaining the crystal structure of the cathode. Another way to engineer and control the cathode specific capacity, IRCL and average voltage is by having a nanocoating covering the surface of the cathode. The nanocoating has been shown to stabilize the cathode structure by preventing unwanted side reactions with the electrolyte and reducing the amount of cathode TM dissolution. As part of the project, various nanocoating compositions, as well as coating thicknesses will be explored and optimized. The thickness and uniformity of the nanocoating are dependent on the particle morphology (particle size, surface area and porosity) and reaction conditions. Initial testing is performed using coin cells or 1Ah pouch cells and will be scaled up to larger pouch cells. Electrochemical and battery testing are being performed, along with material characterization using various analytical techniques. Results In this first USABC project, Envia has met a majority of the stringent requirements for EV batteries. Envia demonstrated meeting the gravimetric and volumetric power and energy targets from 20Ah capacity pouch cells. Low temperature energy retention was shown to meet the specifications from room temperature to -30°C. DST cycle life testing is still ongoing with the latest data showing greater than 800 DST cycles (9 RPTs) while both energy and discharge power continue to stay above the 80% beginning of life (BOL) target (see Figure III - 1). Energy Storage R&D 30 FY 2013 Annual Progress Report Figure III - 1: DST cycle life test results in terms of energy (a) and discharge power (b) for 20Ah capacity pouch cells Calendar life testing is also ongoing with promising results being shown after seven months of testing. The models to properly predict the calendar life continue to be developed as more data continues to be collected. During the course of the project, the cell-to-pack conversion factors and pack-related costs were calculated by working with a system integrationPDF Image | Advanced Battery Development

PDF Search Title:

Advanced Battery DevelopmentOriginal File Name Searched:

APR13_Energy_Storage_d_III_Adv_Battery_Dev_0.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Sand Battery Sand and Paraffin for TES Thermo Energy Storage More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |