PDF Publication Title:

Text from PDF Page: 021

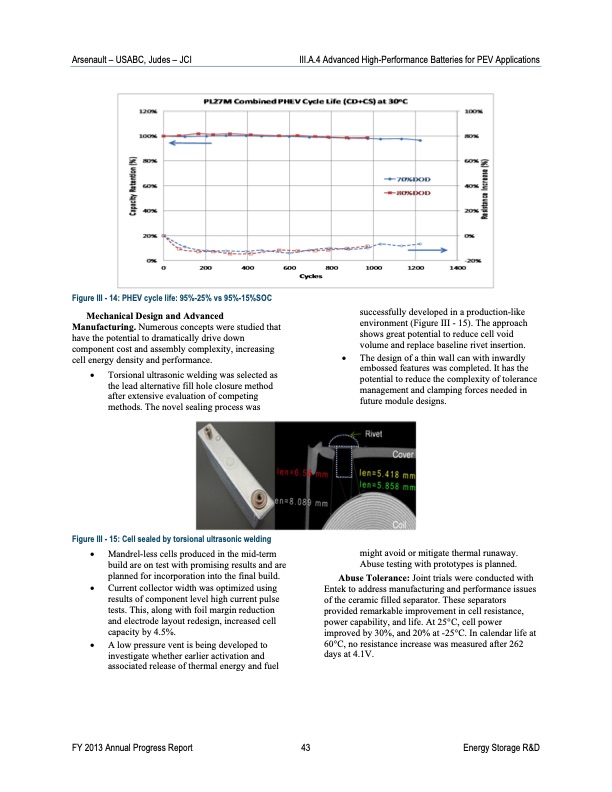

Arsenault – USABC, Judes – JCI III.A.4 Advanced High-Performance Batteries for PEV Applications Figure III - 14: PHEV cycle life: 95%-25% vs 95%-15%SOC Mechanical Design and Advanced Manufacturing. Numerous concepts were studied that have the potential to dramatically drive down component cost and assembly complexity, increasing cell energy density and performance. Torsional ultrasonic welding was selected as the lead alternative fill hole closure method after extensive evaluation of competing methods. The novel sealing process was successfully developed in a production-like environment (Figure III - 15). The approach shows great potential to reduce cell void volume and replace baseline rivet insertion. The design of a thin wall can with inwardly embossed features was completed. It has the potential to reduce the complexity of tolerance management and clamping forces needed in future module designs. Figure III - 15: Cell sealed by torsional ultrasonic welding Mandrel-less cells produced in the mid-term build are on test with promising results and are planned for incorporation into the final build. Current collector width was optimized using results of component level high current pulse tests. This, along with foil margin reduction and electrode layout redesign, increased cell capacity by 4.5%. A low pressure vent is being developed to investigate whether earlier activation and associated release of thermal energy and fuel might avoid or mitigate thermal runaway. Abuse testing with prototypes is planned. Abuse Tolerance: Joint trials were conducted with Entek to address manufacturing and performance issues of the ceramic filled separator. These separators provided remarkable improvement in cell resistance, power capability, and life. At 25°C, cell power improved by 30%, and 20% at -25°C. In calendar life at 60°C, no resistance increase was measured after 262 days at 4.1V. FY 2013 Annual Progress Report 43 Energy Storage R&DPDF Image | Advanced Battery Development

PDF Search Title:

Advanced Battery DevelopmentOriginal File Name Searched:

APR13_Energy_Storage_d_III_Adv_Battery_Dev_0.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Sand Battery Sand and Paraffin for TES Thermo Energy Storage More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |