PDF Publication Title:

Text from PDF Page: 025

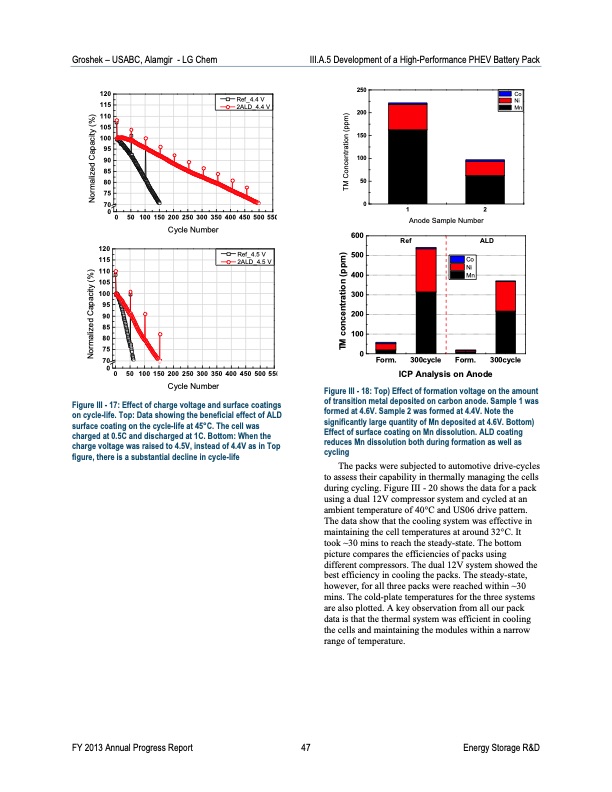

Groshek – USABC, Alamgir - LG Chem III.A.5 Development of a High-Performance PHEV Battery Pack 120 115 110 105 100 95 90 85 80 75 70 0 120 115 110 105 100 95 90 85 80 75 70 0 0 50 100 150 200 250 300 350 400 450 500 550 Cycle Number 250 200 150 100 50 0 600 500 400 300 200 100 0 12 Anode Sample Number Ref_4.4 V 2ALD_4.4 V Ref_4.5 V 2ALD_4.5 V 0 50 100 150 200 250 300 350 400 450 500 550 Cycle Number Figure III - 17: Effect of charge voltage and surface coatings on cycle-life. Top: Data showing the beneficial effect of ALD surface coating on the cycle-life at 45°C. The cell was charged at 0.5C and discharged at 1C. Bottom: When the charge voltage was raised to 4.5V, instead of 4.4V as in Top figure, there is a substantial decline in cycle-life Figure III - 18: Top) Effect of formation voltage on the amount of transition metal deposited on carbon anode. Sample 1 was formed at 4.6V. Sample 2 was formed at 4.4V. Note the significantly large quantity of Mn deposited at 4.6V. Bottom) Effect of surface coating on Mn dissolution. ALD coating reduces Mn dissolution both during formation as well as cycling The packs were subjected to automotive drive-cycles to assess their capability in thermally managing the cells during cycling. Figure III - 20 shows the data for a pack using a dual 12V compressor system and cycled at an ambient temperature of 40°C and US06 drive pattern. The data show that the cooling system was effective in maintaining the cell temperatures at around 32°C. It took ~30 mins to reach the steady-state. The bottom picture compares the efficiencies of packs using different compressors. The dual 12V system showed the best efficiency in cooling the packs. The steady-state, however, for all three packs were reached within ~30 mins. The cold-plate temperatures for the three systems are also plotted. A key observation from all our pack data is that the thermal system was efficient in cooling the cells and maintaining the modules within a narrow range of temperature. FY 2013 Annual Progress Report 47 Energy Storage R&D Form. 300cycle ICP Analysis on Anode Form. 300cycle Co Ni Mn Ref ALD Co Ni Mn Normalized Capacity (%) Normalized Capacity (%) TM concentration (ppm) TM Concentration (ppm)PDF Image | Advanced Battery Development

PDF Search Title:

Advanced Battery DevelopmentOriginal File Name Searched:

APR13_Energy_Storage_d_III_Adv_Battery_Dev_0.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Sand Battery Sand and Paraffin for TES Thermo Energy Storage More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |