PDF Publication Title:

Text from PDF Page: 029

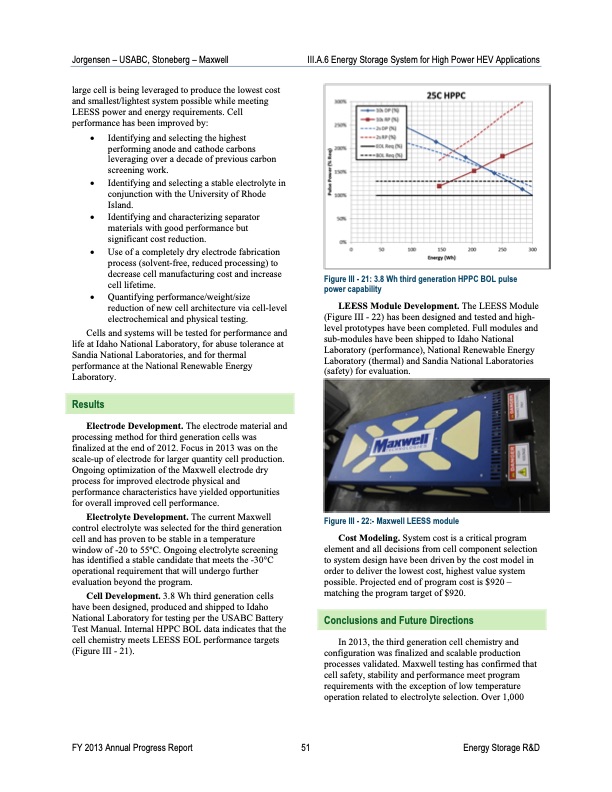

Jorgensen – USABC, Stoneberg – Maxwell III.A.6 Energy Storage System for High Power HEV Applications large cell is being leveraged to produce the lowest cost and smallest/lightest system possible while meeting LEESS power and energy requirements. Cell performance has been improved by: Identifying and selecting the highest performing anode and cathode carbons leveraging over a decade of previous carbon screening work. Identifying and selecting a stable electrolyte in conjunction with the University of Rhode Island. Identifying and characterizing separator materials with good performance but significant cost reduction. Use of a completely dry electrode fabrication process (solvent-free, reduced processing) to decrease cell manufacturing cost and increase cell lifetime. Quantifying performance/weight/size reduction of new cell architecture via cell-level electrochemical and physical testing. Figure III - 21: 3.8 Wh third generation HPPC BOL pulse power capability LEESS Module Development. The LEESS Module (Figure III - 22) has been designed and tested and high- level prototypes have been completed. Full modules and sub-modules have been shipped to Idaho National Laboratory (performance), National Renewable Energy Laboratory (thermal) and Sandia National Laboratories (safety) for evaluation. Cells life at Idaho National Laboratory, for abuse tolerance at Sandia National Laboratories, and for thermal performance at the National Renewable Energy Laboratory. Results Electrode Development. The electrode material and processing method for third generation cells was finalized at the end of 2012. Focus in 2013 was on the scale-up of electrode for larger quantity cell production. Ongoing optimization of the Maxwell electrode dry process for improved electrode physical and performance characteristics have yielded opportunities for overall improved cell performance. Electrolyte Development. The current Maxwell control electrolyte was selected for the third generation cell and has proven to be stable in a temperature window of -20 to 55oC. Ongoing electrolyte screening has identified a stable candidate that meets the -30°C operational requirement that will undergo further evaluation beyond the program. Cell Development. 3.8 Wh third generation cells have been designed, produced and shipped to Idaho National Laboratory for testing per the USABC Battery Test Manual. Internal HPPC BOL data indicates that the cell chemistry meets LEESS EOL performance targets (Figure III - 21). and systems will be tested for performance and Figure III - 22:- Maxwell LEESS module Cost Modeling. System cost is a critical program element and all decisions from cell component selection to system design have been driven by the cost model in order to deliver the lowest cost, highest value system possible. Projected end of program cost is $920 – matching the program target of $920. Conclusions and Future Directions In 2013, the third generation cell chemistry and configuration was finalized and scalable production processes validated. Maxwell testing has confirmed that cell safety, stability and performance meet program requirements with the exception of low temperature operation related to electrolyte selection. Over 1,000 FY 2013 Annual Progress Report 51 Energy Storage R&DPDF Image | Advanced Battery Development

PDF Search Title:

Advanced Battery DevelopmentOriginal File Name Searched:

APR13_Energy_Storage_d_III_Adv_Battery_Dev_0.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Sand Battery Sand and Paraffin for TES Thermo Energy Storage More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |