PDF Publication Title:

Text from PDF Page: 042

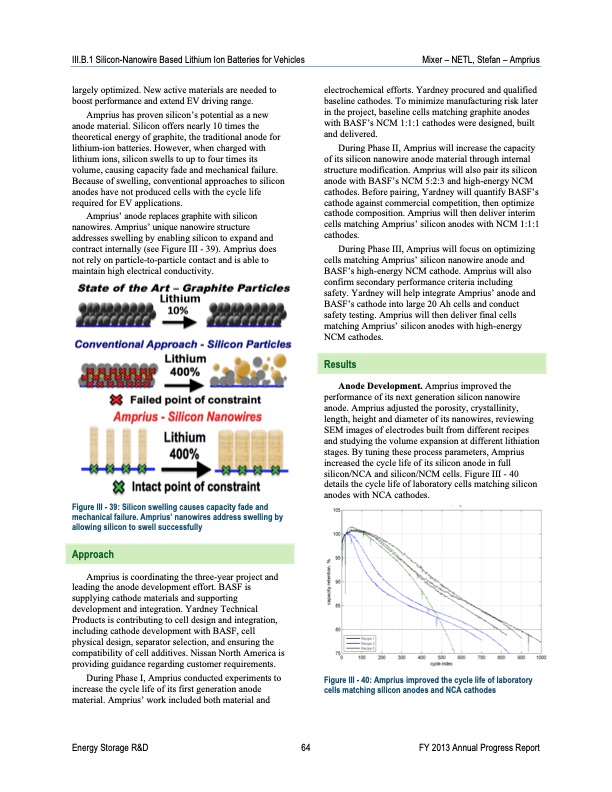

III.B.1 Silicon-Nanowire Based Lithium Ion Batteries for Vehicles Mixer – NETL, Stefan – Amprius largely optimized. New active materials are needed to boost performance and extend EV driving range. Amprius has proven silicon’s potential as a new anode material. Silicon offers nearly 10 times the theoretical energy of graphite, the traditional anode for lithium-ion batteries. However, when charged with lithium ions, silicon swells to up to four times its volume, causing capacity fade and mechanical failure. Because of swelling, conventional approaches to silicon anodes have not produced cells with the cycle life required for EV applications. Amprius’ anode replaces graphite with silicon nanowires. Amprius’ unique nanowire structure addresses swelling by enabling silicon to expand and contract internally (see Figure III - 39). Amprius does not rely on particle-to-particle contact and is able to maintain high electrical conductivity. electrochemical efforts. Yardney procured and qualified baseline cathodes. To minimize manufacturing risk later in the project, baseline cells matching graphite anodes with BASF’s NCM 1:1:1 cathodes were designed, built and delivered. During Phase II, Amprius will increase the capacity of its silicon nanowire anode material through internal structure modification. Amprius will also pair its silicon anode with BASF’s NCM 5:2:3 and high-energy NCM cathodes. Before pairing, Yardney will quantify BASF’s cathode against commercial competition, then optimize cathode composition. Amprius will then deliver interim cells matching Amprius’ silicon anodes with NCM 1:1:1 cathodes. During Phase III, Amprius will focus on optimizing cells matching Amprius’ silicon nanowire anode and BASF’s high-energy NCM cathode. Amprius will also confirm secondary performance criteria including safety. Yardney will help integrate Amprius’ anode and BASF’s cathode into large 20 Ah cells and conduct safety testing. Amprius will then deliver final cells matching Amprius’ silicon anodes with high-energy NCM cathodes. Results Anode Development. Amprius improved the performance of its next generation silicon nanowire anode. Amprius adjusted the porosity, crystallinity, length, height and diameter of its nanowires, reviewing SEM images of electrodes built from different recipes and studying the volume expansion at different lithiation stages. By tuning these process parameters, Amprius increased the cycle life of its silicon anode in full silicon/NCA and silicon/NCM cells. Figure III - 40 details the cycle life of laboratory cells matching silicon anodes with NCA cathodes. Figure III - 39: Silicon swelling causes capacity fade and mechanical failure. Amprius’ nanowires address swelling by allowing silicon to swell successfully Approach Amprius is coordinating the three-year project and leading the anode development effort. BASF is supplying cathode materials and supporting development and integration. Yardney Technical Products is contributing to cell design and integration, including cathode development with BASF, cell physical design, separator selection, and ensuring the compatibility of cell additives. Nissan North America is providing guidance regarding customer requirements. During Phase I, Amprius conducted experiments to increase the cycle life of its first generation anode material. Amprius’ work included both material and Figure III - 40: Amprius improved the cycle life of laboratory cells matching silicon anodes and NCA cathodes Energy Storage R&D 64 FY 2013 Annual Progress ReportPDF Image | Advanced Battery Development

PDF Search Title:

Advanced Battery DevelopmentOriginal File Name Searched:

APR13_Energy_Storage_d_III_Adv_Battery_Dev_0.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Sand Battery Sand and Paraffin for TES Thermo Energy Storage More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |