PDF Publication Title:

Text from PDF Page: 054

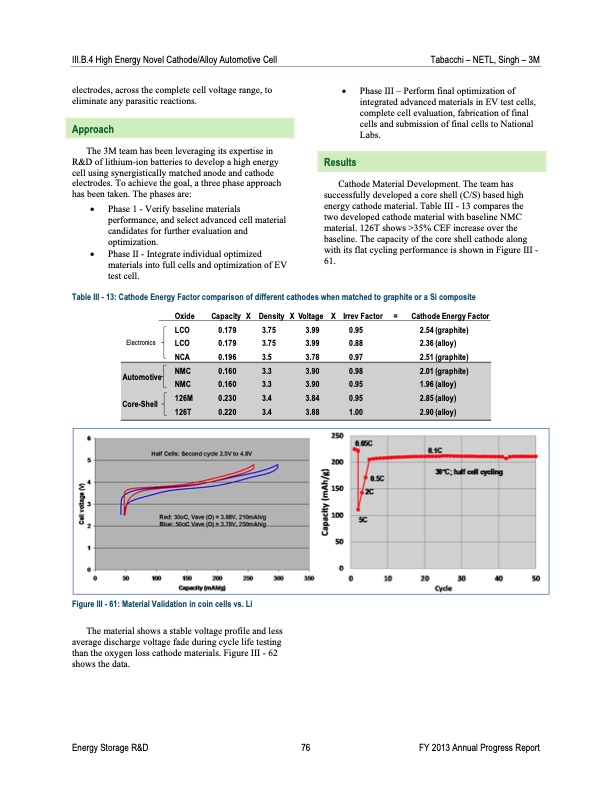

III.B.4 High Energy Novel Cathode/Alloy Automotive Cell Tabacchi – NETL, Singh – 3M electrodes, across the complete cell voltage range, to eliminate any parasitic reactions. Approach The 3M team has been leveraging its expertise in R&D of lithium-ion batteries to develop a high energy cell using synergistically matched anode and cathode electrodes. To achieve the goal, a three phase approach has been taken. The phases are: Phase 1 - V erify baseline materials performance, and select advanced cell material candidates for further evaluation and optimization. Phase II - Integrate individual optimized materials into full cells and optimization of EV test cell. Results Phase III – Perform final optimization of integrated advanced materials in EV test cells, complete cell evaluation, fabrication of final cells and submission of final cells to National Labs. Table III - 13: Cathode Energy Factor comparison of different cathodes when matched to graphite or a Si composite Oxide LCO LCO NCA Capacity 0.179 0.179 0.196 X Density 3.75 3.75 3.5 X Voltage 3.99 3.99 3.78 X Irrev Factor 0.95 0.88 0.97 = Cathode Energy Factor 2.54 (graphite) 2.36 (alloy) 2.51 (graphite) Cathode Material Development. The team has successfully developed a core shell (C/S) based high energy cathode material. Table III - 13 compares the two developed cathode material with baseline NMC material. 126T shows >35% CEF increase over the baseline. The capacity of the core shell cathode along with its flat cycling performance is shown in Figure III - 61. Electronics Automotive Core-Shell NMC 0.160 3.3 NMC 0.160 3.3 126M 0.230 3.4 126T 0.220 3.4 3.90 0.98 3.90 0.95 3.84 0.95 3.88 1.00 2.01 (graphite) 1.96 (alloy) 2.85 (alloy) 2.90 (alloy) Figure III - 61: Material Validation in coin cells vs. Li The material shows a stable voltage profile and less average discharge voltage fade during cycle life testing than the oxygen loss cathode materials. Figure III - 62 shows the data. Energy Storage R&D 76 FY 2013 Annual Progress ReportPDF Image | Advanced Battery Development

PDF Search Title:

Advanced Battery DevelopmentOriginal File Name Searched:

APR13_Energy_Storage_d_III_Adv_Battery_Dev_0.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Sand Battery Sand and Paraffin for TES Thermo Energy Storage More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |