PDF Publication Title:

Text from PDF Page: 004

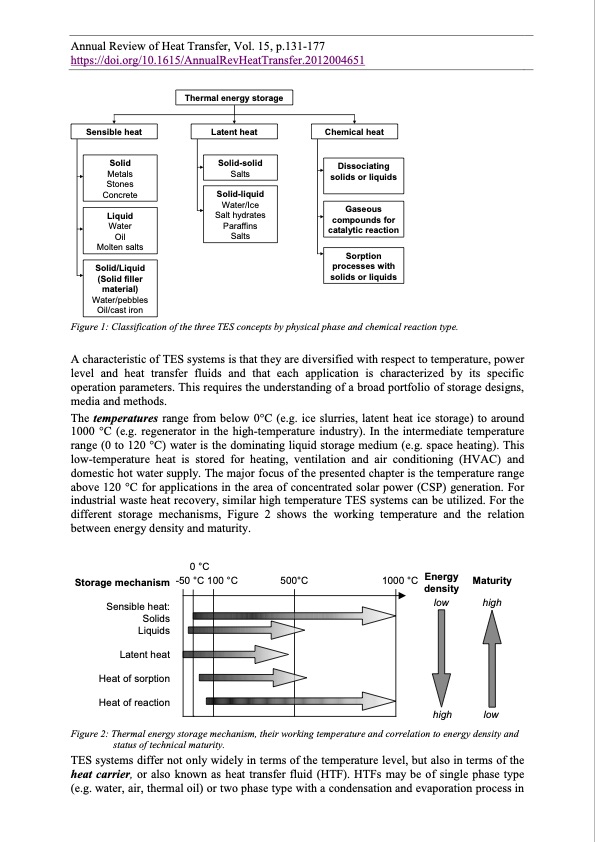

Annual Review of Heat Transfer, Vol. 15, p.131-177 https://doi.org/10.1615/AnnualRevHeatTransfer.2012004651 Sensible heat Solid Metals Stones Concrete Liquid Water Oil Molten salts Solid/Liquid (Solid filler material) Water/pebbles Oil/cast iron Thermal energy storage Latent heat Solid-solid Salts Solid-liquid Water/Ice Salt hydrates Paraffins Salts Chemical heat Dissociating solids or liquids Gaseous compounds for catalytic reaction Sorption processes with solids or liquids Figure 1: Classification of the three TES concepts by physical phase and chemical reaction type. A characteristic of TES systems is that they are diversified with respect to temperature, power level and heat transfer fluids and that each application is characterized by its specific operation parameters. This requires the understanding of a broad portfolio of storage designs, media and methods. The temperatures range from below 0°C (e.g. ice slurries, latent heat ice storage) to around 1000 °C (e.g. regenerator in the high-temperature industry). In the intermediate temperature range (0 to 120 °C) water is the dominating liquid storage medium (e.g. space heating). This low-temperature heat is stored for heating, ventilation and air conditioning (HVAC) and domestic hot water supply. The major focus of the presented chapter is the temperature range above 120 °C for applications in the area of concentrated solar power (CSP) generation. For industrial waste heat recovery, similar high temperature TES systems can be utilized. For the different storage mechanisms, Figure 2 shows the working temperature and the relation between energy density and maturity. Storage mechanism Sensible heat: Solids Liquids Latent heat Heat of sorption Heat of reaction Maturity low high 0 °C -50 °C 100 °C 500°C 1000 °C Energy density Figure 2: Thermal energy storage mechanism, their working temperature and correlation to energy density and status of technical maturity. TES systems differ not only widely in terms of the temperature level, but also in terms of the heat carrier, or also known as heat transfer fluid (HTF). HTFs may be of single phase type (e.g. water, air, thermal oil) or two phase type with a condensation and evaporation process in high lowPDF Image | Annual Review of Heat Transfer

PDF Search Title:

Annual Review of Heat TransferOriginal File Name Searched:

2012_Thermal_Energy_Storage_Materials_and_Systems.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Sand Battery Sand and Paraffin for TES Thermo Energy Storage More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |