PDF Publication Title:

Text from PDF Page: 014

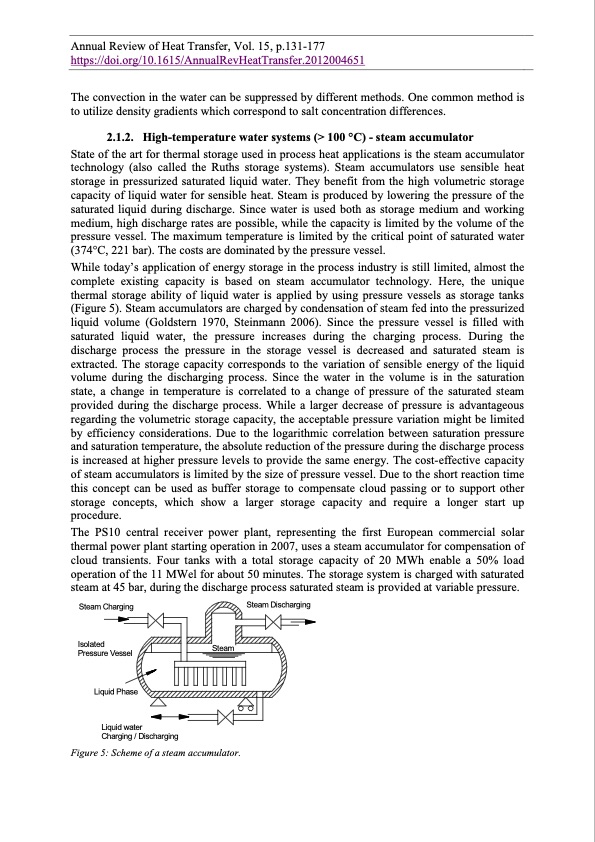

Annual Review of Heat Transfer, Vol. 15, p.131-177 https://doi.org/10.1615/AnnualRevHeatTransfer.2012004651 The convection in the water can be suppressed by different methods. One common method is to utilize density gradients which correspond to salt concentration differences. 2.1.2. High-temperature water systems (> 100 °C) - steam accumulator State of the art for thermal storage used in process heat applications is the steam accumulator technology (also called the Ruths storage systems). Steam accumulators use sensible heat storage in pressurized saturated liquid water. They benefit from the high volumetric storage capacity of liquid water for sensible heat. Steam is produced by lowering the pressure of the saturated liquid during discharge. Since water is used both as storage medium and working medium, high discharge rates are possible, while the capacity is limited by the volume of the pressure vessel. The maximum temperature is limited by the critical point of saturated water (374°C, 221 bar). The costs are dominated by the pressure vessel. While today’s application of energy storage in the process industry is still limited, almost the complete existing capacity is based on steam accumulator technology. Here, the unique thermal storage ability of liquid water is applied by using pressure vessels as storage tanks (Figure 5). Steam accumulators are charged by condensation of steam fed into the pressurized liquid volume (Goldstern 1970, Steinmann 2006). Since the pressure vessel is filled with saturated liquid water, the pressure increases during the charging process. During the discharge process the pressure in the storage vessel is decreased and saturated steam is extracted. The storage capacity corresponds to the variation of sensible energy of the liquid volume during the discharging process. Since the water in the volume is in the saturation state, a change in temperature is correlated to a change of pressure of the saturated steam provided during the discharge process. While a larger decrease of pressure is advantageous regarding the volumetric storage capacity, the acceptable pressure variation might be limited by efficiency considerations. Due to the logarithmic correlation between saturation pressure and saturation temperature, the absolute reduction of the pressure during the discharge process is increased at higher pressure levels to provide the same energy. The cost-effective capacity of steam accumulators is limited by the size of pressure vessel. Due to the short reaction time this concept can be used as buffer storage to compensate cloud passing or to support other storage concepts, which show a larger storage capacity and require a longer start up procedure. The PS10 central receiver power plant, representing the first European commercial solar thermal power plant starting operation in 2007, uses a steam accumulator for compensation of cloud transients. Four tanks with a total storage capacity of 20 MWh enable a 50% load operation of the 11 MWel for about 50 minutes. The storage system is charged with saturated steam at 45 bar, during the discharge process saturated steam is provided at variable pressure. Steam Charging Isolated Pressure Vessel Liquid Phase Liquid water Charging / Discharging Steam Discharging Steam Figure 5: Scheme of a steam accumulator.PDF Image | Annual Review of Heat Transfer

PDF Search Title:

Annual Review of Heat TransferOriginal File Name Searched:

2012_Thermal_Energy_Storage_Materials_and_Systems.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Sand Battery Sand and Paraffin for TES Thermo Energy Storage More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |