PDF Publication Title:

Text from PDF Page: 020

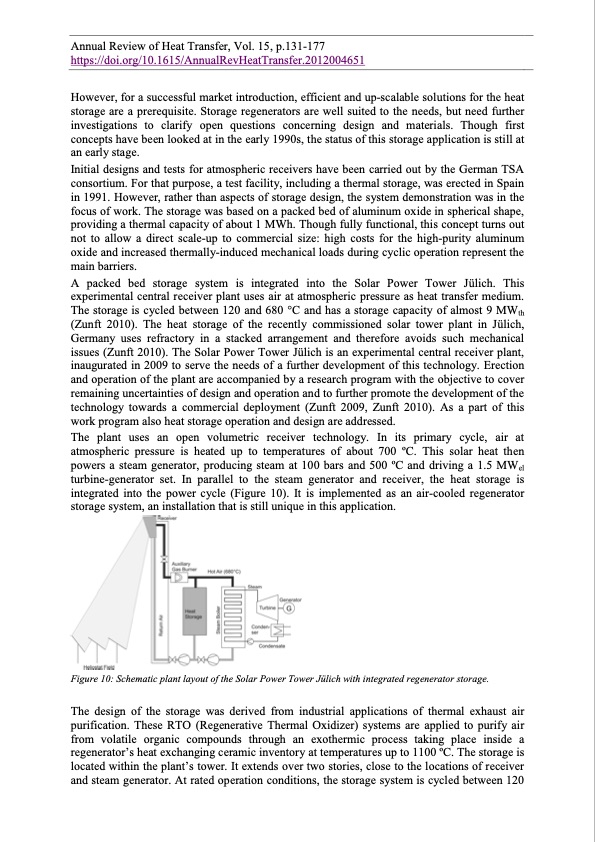

Annual Review of Heat Transfer, Vol. 15, p.131-177 https://doi.org/10.1615/AnnualRevHeatTransfer.2012004651 However, for a successful market introduction, efficient and up-scalable solutions for the heat storage are a prerequisite. Storage regenerators are well suited to the needs, but need further investigations to clarify open questions concerning design and materials. Though first concepts have been looked at in the early 1990s, the status of this storage application is still at an early stage. Initial designs and tests for atmospheric receivers have been carried out by the German TSA consortium. For that purpose, a test facility, including a thermal storage, was erected in Spain in 1991. However, rather than aspects of storage design, the system demonstration was in the focus of work. The storage was based on a packed bed of aluminum oxide in spherical shape, providing a thermal capacity of about 1 MWh. Though fully functional, this concept turns out not to allow a direct scale-up to commercial size: high costs for the high-purity aluminum oxide and increased thermally-induced mechanical loads during cyclic operation represent the main barriers. A packed bed storage system is integrated into the Solar Power Tower Jülich. This experimental central receiver plant uses air at atmospheric pressure as heat transfer medium. The storage is cycled between 120 and 680 °C and has a storage capacity of almost 9 MWth (Zunft 2010). The heat storage of the recently commissioned solar tower plant in Jülich, Germany uses refractory in a stacked arrangement and therefore avoids such mechanical issues (Zunft 2010). The Solar Power Tower Jülich is an experimental central receiver plant, inaugurated in 2009 to serve the needs of a further development of this technology. Erection and operation of the plant are accompanied by a research program with the objective to cover remaining uncertainties of design and operation and to further promote the development of the technology towards a commercial deployment (Zunft 2009, Zunft 2010). As a part of this work program also heat storage operation and design are addressed. The plant uses an open volumetric receiver technology. In its primary cycle, air at atmospheric pressure is heated up to temperatures of about 700 oC. This solar heat then powers a steam generator, producing steam at 100 bars and 500 oC and driving a 1.5 MWel turbine-generator set. In parallel to the steam generator and receiver, the heat storage is integrated into the power cycle (Figure 10). It is implemented as an air-cooled regenerator storage system, an installation that is still unique in this application. Figure 10: Schematic plant layout of the Solar Power Tower Jülich with integrated regenerator storage. The design of the storage was derived from industrial applications of thermal exhaust air purification. These RTO (Regenerative Thermal Oxidizer) systems are applied to purify air from volatile organic compounds through an exothermic process taking place inside a regenerator’s heat exchanging ceramic inventory at temperatures up to 1100 oC. The storage is located within the plant’s tower. It extends over two stories, close to the locations of receiver and steam generator. At rated operation conditions, the storage system is cycled between 120PDF Image | Annual Review of Heat Transfer

PDF Search Title:

Annual Review of Heat TransferOriginal File Name Searched:

2012_Thermal_Energy_Storage_Materials_and_Systems.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Sand Battery Sand and Paraffin for TES Thermo Energy Storage More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |