PDF Publication Title:

Text from PDF Page: 021

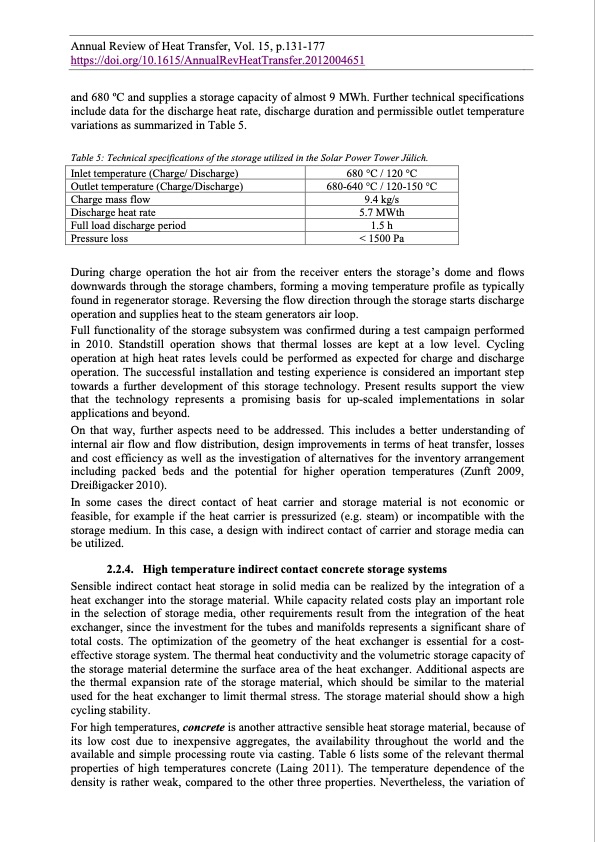

Annual Review of Heat Transfer, Vol. 15, p.131-177 https://doi.org/10.1615/AnnualRevHeatTransfer.2012004651 and 680 oC and supplies a storage capacity of almost 9 MWh. Further technical specifications include data for the discharge heat rate, discharge duration and permissible outlet temperature variations as summarized in Table 5. Table 5: Technical specifications of the storage utilized in the Solar Power Tower Jülich. Inlet temperature (Charge/ Discharge) Outlet temperature (Charge/Discharge) Charge mass flow Discharge heat rate Full load discharge period Pressure loss 680 °C / 120 °C 680-640 °C / 120-150 °C 9.4 kg/s 5.7 MWth 1.5 h < 1500 Pa During charge operation the hot air from the receiver enters the storage’s dome and flows downwards through the storage chambers, forming a moving temperature profile as typically found in regenerator storage. Reversing the flow direction through the storage starts discharge operation and supplies heat to the steam generators air loop. Full functionality of the storage subsystem was confirmed during a test campaign performed in 2010. Standstill operation shows that thermal losses are kept at a low level. Cycling operation at high heat rates levels could be performed as expected for charge and discharge operation. The successful installation and testing experience is considered an important step towards a further development of this storage technology. Present results support the view that the technology represents a promising basis for up-scaled implementations in solar applications and beyond. On that way, further aspects need to be addressed. This includes a better understanding of internal air flow and flow distribution, design improvements in terms of heat transfer, losses and cost efficiency as well as the investigation of alternatives for the inventory arrangement including packed beds and the potential for higher operation temperatures (Zunft 2009, Dreißigacker 2010). In some cases the direct contact of heat carrier and storage material is not economic or feasible, for example if the heat carrier is pressurized (e.g. steam) or incompatible with the storage medium. In this case, a design with indirect contact of carrier and storage media can be utilized. 2.2.4. High temperature indirect contact concrete storage systems Sensible indirect contact heat storage in solid media can be realized by the integration of a heat exchanger into the storage material. While capacity related costs play an important role in the selection of storage media, other requirements result from the integration of the heat exchanger, since the investment for the tubes and manifolds represents a significant share of total costs. The optimization of the geometry of the heat exchanger is essential for a cost- effective storage system. The thermal heat conductivity and the volumetric storage capacity of the storage material determine the surface area of the heat exchanger. Additional aspects are the thermal expansion rate of the storage material, which should be similar to the material used for the heat exchanger to limit thermal stress. The storage material should show a high cycling stability. For high temperatures, concrete is another attractive sensible heat storage material, because of its low cost due to inexpensive aggregates, the availability throughout the world and the available and simple processing route via casting. Table 6 lists some of the relevant thermal properties of high temperatures concrete (Laing 2011). The temperature dependence of the density is rather weak, compared to the other three properties. Nevertheless, the variation ofPDF Image | Annual Review of Heat Transfer

PDF Search Title:

Annual Review of Heat TransferOriginal File Name Searched:

2012_Thermal_Energy_Storage_Materials_and_Systems.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Sand Battery Sand and Paraffin for TES Thermo Energy Storage More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |