PDF Publication Title:

Text from PDF Page: 022

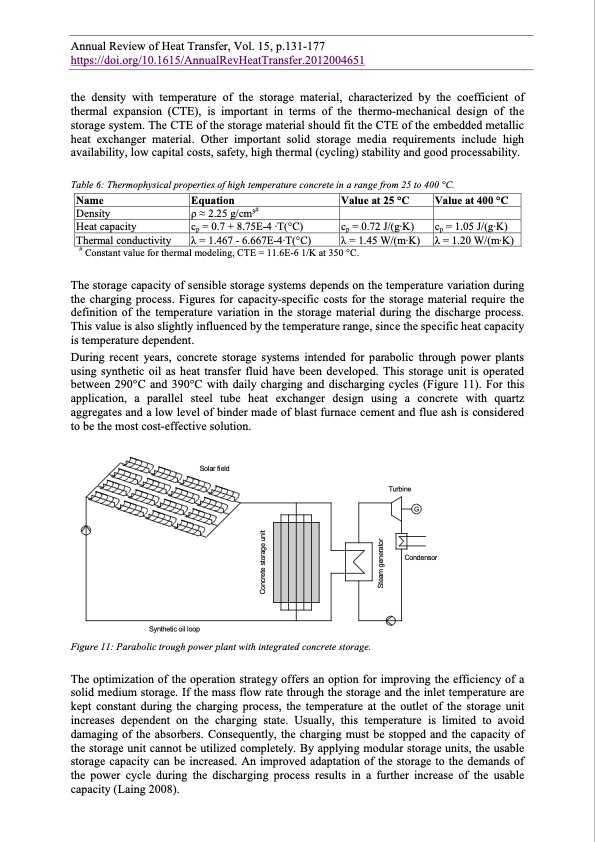

Annual Review of Heat Transfer, Vol. 15, p.131-177 https://doi.org/10.1615/AnnualRevHeatTransfer.2012004651 the density with temperature of the storage material, characterized by the coefficient of thermal expansion (CTE), is important in terms of the thermo-mechanical design of the storage system. The CTE of the storage material should fit the CTE of the embedded metallic heat exchanger material. Other important solid storage media requirements include high availability, low capital costs, safety, high thermal (cycling) stability and good processability. Table 6: Thermophysical properties of high temperature concrete in a range from 25 to 400 °C. Name Density Heat capacity Thermal conductivity The storage capacity of sensible storage systems depends on the temperature variation during the charging process. Figures for capacity-specific costs for the storage material require the definition of the temperature variation in the storage material during the discharge process. This value is also slightly influenced by the temperature range, since the specific heat capacity is temperature dependent. During recent years, concrete storage systems intended for parabolic through power plants using synthetic oil as heat transfer fluid have been developed. This storage unit is operated between 290°C and 390°C with daily charging and discharging cycles (Figure 11). For this application, a parallel steel tube heat exchanger design using a concrete with quartz aggregates and a low level of binder made of blast furnace cement and flue ash is considered to be the most cost-effective solution. Equation ρ ≈ 2.25 g/cm3# cp = 0.7 + 8.75E-4 ∙T(°C) λ = 1.467 - 6.667E-4∙T(°C) Value at 25 °C cp = 0.72 J/(g∙K) Value at 400 °C cp = 1.05 J/(g∙K) λ = 1.20 W/(m∙K) λ = 1.45 W/(m∙K) # Constant value for thermal modeling, CTE = 11.6E-6 1/K at 350 °C. Solar field Turbine G Condensor Synthetic oil loop Figure 11: Parabolic trough power plant with integrated concrete storage. The optimization of the operation strategy offers an option for improving the efficiency of a solid medium storage. If the mass flow rate through the storage and the inlet temperature are kept constant during the charging process, the temperature at the outlet of the storage unit increases dependent on the charging state. Usually, this temperature is limited to avoid damaging of the absorbers. Consequently, the charging must be stopped and the capacity of the storage unit cannot be utilized completely. By applying modular storage units, the usable storage capacity can be increased. An improved adaptation of the storage to the demands of the power cycle during the discharging process results in a further increase of the usable capacity (Laing 2008). Concrete storage unit Steam generatorPDF Image | Annual Review of Heat Transfer

PDF Search Title:

Annual Review of Heat TransferOriginal File Name Searched:

2012_Thermal_Energy_Storage_Materials_and_Systems.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Sand Battery Sand and Paraffin for TES Thermo Energy Storage More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |