PDF Publication Title:

Text from PDF Page: 028

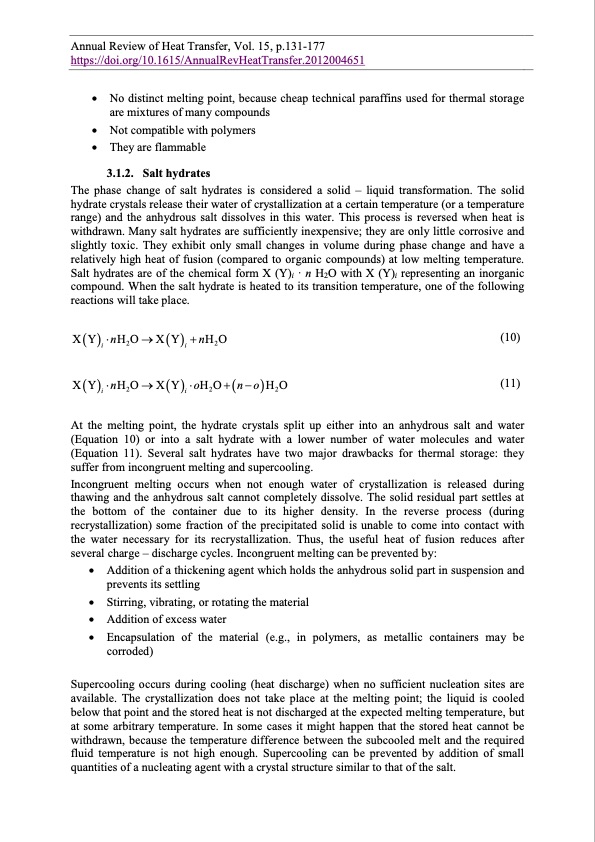

Annual Review of Heat Transfer, Vol. 15, p.131-177 https://doi.org/10.1615/AnnualRevHeatTransfer.2012004651 No distinct melting point, because cheap technical paraffins used for thermal storage are mixtures of many compounds Not compatible with polymers They are flammable 3.1.2. Salt hydrates The phase change of salt hydrates is considered a solid – liquid transformation. The solid hydrate crystals release their water of crystallization at a certain temperature (or a temperature range) and the anhydrous salt dissolves in this water. This process is reversed when heat is withdrawn. Many salt hydrates are sufficiently inexpensive; they are only little corrosive and slightly toxic. They exhibit only small changes in volume during phase change and have a relatively high heat of fusion (compared to organic compounds) at low melting temperature. Salt hydrates are of the chemical form X (Y)i · n H2O with X (Y)i representing an inorganic compound. When the salt hydrate is heated to its transition temperature, one of the following reactions will take place. XYi nH2OXYi nH2O XYi nH2OXYi oH2OnoH2O (10) (11) At the melting point, the hydrate crystals split up either into an anhydrous salt and water (Equation 10) or into a salt hydrate with a lower number of water molecules and water (Equation 11). Several salt hydrates have two major drawbacks for thermal storage: they suffer from incongruent melting and supercooling. Incongruent melting occurs when not enough water of crystallization is released during thawing and the anhydrous salt cannot completely dissolve. The solid residual part settles at the bottom of the container due to its higher density. In the reverse process (during recrystallization) some fraction of the precipitated solid is unable to come into contact with the water necessary for its recrystallization. Thus, the useful heat of fusion reduces after several charge – discharge cycles. Incongruent melting can be prevented by: Addition of a thickening agent which holds the anhydrous solid part in suspension and prevents its settling Stirring, vibrating, or rotating the material Addition of excess water Encapsulation of the material (e.g., in polymers, as metallic containers may be corroded) Supercooling occurs during cooling (heat discharge) when no sufficient nucleation sites are available. The crystallization does not take place at the melting point; the liquid is cooled below that point and the stored heat is not discharged at the expected melting temperature, but at some arbitrary temperature. In some cases it might happen that the stored heat cannot be withdrawn, because the temperature difference between the subcooled melt and the required fluid temperature is not high enough. Supercooling can be prevented by addition of small quantities of a nucleating agent with a crystal structure similar to that of the salt.PDF Image | Annual Review of Heat Transfer

PDF Search Title:

Annual Review of Heat TransferOriginal File Name Searched:

2012_Thermal_Energy_Storage_Materials_and_Systems.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Sand Battery Sand and Paraffin for TES Thermo Energy Storage More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |