PDF Publication Title:

Text from PDF Page: 014

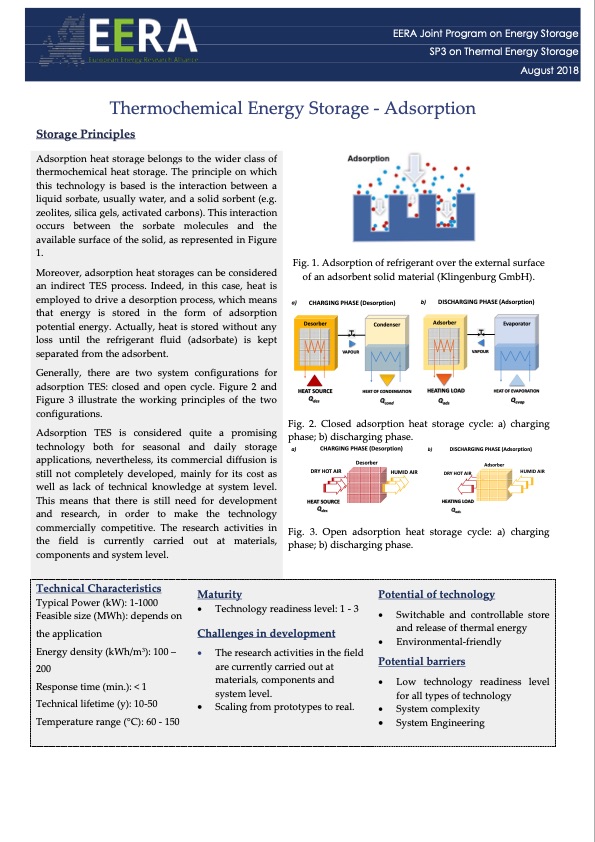

Thermochemical Energy Storage - Adsorption Storage Principles Adsorption heat storage belongs to the wider class of thermochemical heat storage. The principle on which this technology is based is the interaction between a liquid sorbate, usually water, and a solid sorbent (e.g. zeolites, silica gels, activated carbons). This interaction occurs between the sorbate molecules and the available surface of the solid, as represented in Figure 1. Moreover, adsorption heat storages can be considered an indirect TES process. Indeed, in this case, heat is employed to drive a desorption process, which means that energy is stored in the form of adsorption potential energy. Actually, heat is stored without any loss until the refrigerant fluid (adsorbate) is kept separated from the adsorbent. Generally, there are two system configurations for adsorption TES: closed and open cycle. Figure 2 and Figure 3 illustrate the working principles of the two configurations. Adsorption TES is considered quite a promising technology both for seasonal and daily storage applications, nevertheless, its commercial diffusion is still not completely developed, mainly for its cost as well as lack of technical knowledge at system level. This means that there is still need for development and research, in order to make the technology commercially competitive. The research activities in the field is currently carried out at materials, components and system level. Fig. 1. Adsorption of refrigerant over the external surface of an adsorbent solid material (Klingenburg GmbH). a) CHARGING PHASE (Desorption) b) DISCHARGING PHASE (Adsorption) VAPOUR CHARGING PHASE (Desorption) Evaporator Condenser VAPOUR HEAT SOURCE HEAT OF CONDENSATION a) HEATING LOAD HEAT OF EVAPORATION Q Desorber des Q Q cond ads Q phase; b) discharging phase. Qdes DISCHARGING PHASE (Adsorption) Adsorber a) b) CHARGING PHASE (Desorption) Desorber b) DRY HOT AIR eHvaUpMID AIR Fig. 2. Closed adsorption heat storage cycle: a) charging HEAT SOURCE DRY HOT AIR HEAT SOURCE HUMID AIR DRY HOT AIR HUMID AIR Q des HEATING Q LOAD ads DISCHARGING PHASE (Adsorption) Fig. 3. Open adsorption heat storage cycle: a) charging Qads Potential of technology phase; b) discharging phase. DRY HOT AIR HEATING LOAD Adsorber HUMID AIR Technical Characteristics Typical Power (kW): 1-1000 Feasible size (MWh): depends on the application Energy density (kWh/m3): 100 – 200 Response time (min.): < 1 Technical lifetime (y): 10-50 Temperature range (°C): 60 - 150 Maturity Technology readiness level: 1 - 3 Challenges in development The research activities in the field are currently carried out at materials, components and system level. Scaling from prototypes to real. Switchable and controllable store and release of thermal energy Environmental-friendly Potential barriers Low technology readiness level for all types of technology System complexity System Engineering Desorber Adsorber EERA Joint Program on Energy Storage SP3 on Thermal Energy Storage August 2018PDF Image | Brochure on Thermal Energy Storage Technologies

PDF Search Title:

Brochure on Thermal Energy Storage TechnologiesOriginal File Name Searched:

tes-brochure.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Sand Battery Sand and Paraffin for TES Thermo Energy Storage More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |