PDF Publication Title:

Text from PDF Page: 004

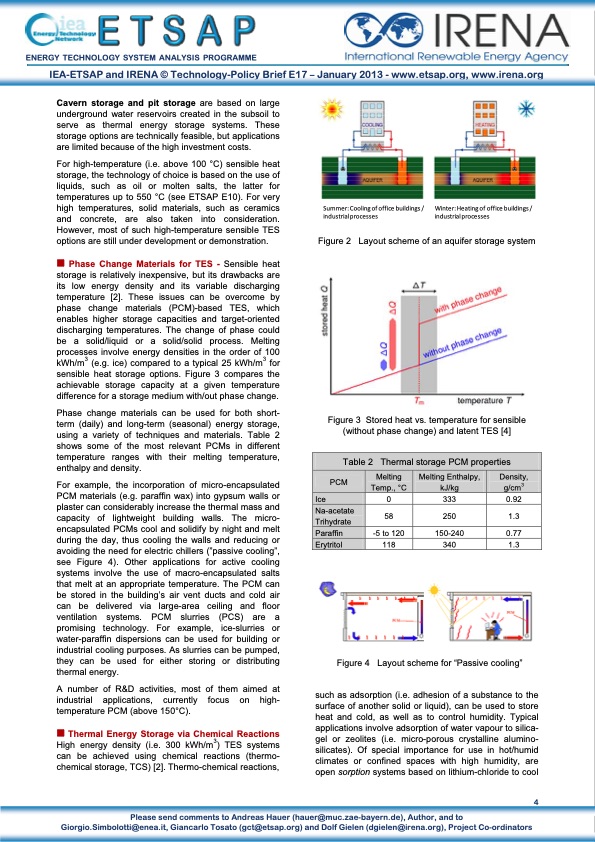

ENERGY TECHNOLOGY SYSTEM ANALYSIS PROGRAMME IEA-ETSAP and IRENA © Technology-Policy Brief E17 – January 2013 - www.etsap.org, www.irena.org Cavern storage and pit storage are based on large underground water reservoirs created in the subsoil to serve as thermal energy storage systems. These storage options are technically feasible, but applications are limited because of the high investment costs. For high-temperature (i.e. above 100 °C) sensible heat storage, the technology of choice is based on the use of liquids, such as oil or molten salts, the latter for temperatures up to 550 °C (see ETSAP E10). For very high temperatures, solid materials, such as ceramics and concrete, are also taken into consideration. However, most of such high-temperature sensible TES options are still under development or demonstration. Phase Change Materials for TES - Sensible heat storage is relatively inexpensive, but its drawbacks are its low energy density and its variable discharging temperature [2]. These issues can be overcome by phase change materials (PCM)-based TES, which enables higher storage capacities and target-oriented discharging temperatures. The change of phase could be a solid/liquid or a solid/solid process. Melting processes involve energy densities in the order of 100 kWh/m3 (e.g. ice) compared to a typical 25 kWh/m3 for sensible heat storage options. Figure 3 compares the achievable storage capacity at a given temperature difference for a storage medium with/out phase change. Phase change materials can be used for both short- term (daily) and long-term (seasonal) energy storage, using a variety of techniques and materials. Table 2 shows some of the most relevant PCMs in different temperature ranges with their melting temperature, enthalpy and density. For example, the incorporation of micro-encapsulated PCM materials (e.g. paraffin wax) into gypsum walls or plaster can considerably increase the thermal mass and capacity of lightweight building walls. The micro- encapsulated PCMs cool and solidify by night and melt during the day, thus cooling the walls and reducing or avoiding the need for electric chillers (”passive cooling”, see Figure 4). Other applications for active cooling systems involve the use of macro-encapsulated salts that melt at an appropriate temperature. The PCM can be stored in the building’s air vent ducts and cold air can be delivered via large-area ceiling and floor ventilation systems. PCM slurries (PCS) are a promising technology. For example, ice-slurries or water-paraffin dispersions can be used for building or industrial cooling purposes. As slurries can be pumped, they can be used for either storing or distributing thermal energy. A number of R&D activities, most of them aimed at industrial applications, currently focus on high- temperature PCM (above 150°C). Thermal Energy Storage via Chemical Reactions High energy density (i.e. 300 kWh/m3) TES systems can be achieved using chemical reactions (thermo- chemical storage, TCS) [2]. Thermo-chemical reactions, Summer: Cooling of office buildings / industrial processes Winter: Heating of office buildings / industrial processes Figure 2 Layout scheme of an aquifer storage system Figure 3 Stored heat vs. temperature for sensible (without phase change) and latent TES [4] Table 2 Thermal storage PCM properties PCM Melting Temp., °C Melting Enthalpy, kJ/kg Density, g/cm3 Ice Na-acetate Trihydrate Paraffin Erytritol 4 Giorgio.Simbolotti@enea.it, Giancarlo Tosato (gct@etsap.org) and Dolf Gielen (dgielen@irena.org), Project Co-ordinators Figure 4 0 333 0.92 58 250 1.3 -5 to 120 150-240 0.77 118 340 1.3 Layout scheme for “Passive cooling” such as adsorption (i.e. adhesion of a substance to the surface of another solid or liquid), can be used to store heat and cold, as well as to control humidity. Typical applications involve adsorption of water vapour to silica- gel or zeolites (i.e. micro-porous crystalline alumino- silicates). Of special importance for use in hot/humid climates or confined spaces with high humidity, are open sorption systems based on lithium-chloride to cool Please send comments to Andreas Hauer (hauer@muc.zae-bayern.de), Author, and toPDF Image | ENERGY TECHNOLOGY SYSTEM ANALYSIS

PDF Search Title:

ENERGY TECHNOLOGY SYSTEM ANALYSISOriginal File Name Searched:

E17IR-ThEnergy Stor_AH_Jan2013_final_GSOK.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Sand Battery Sand and Paraffin for TES Thermo Energy Storage More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |