PDF Publication Title:

Text from PDF Page: 005

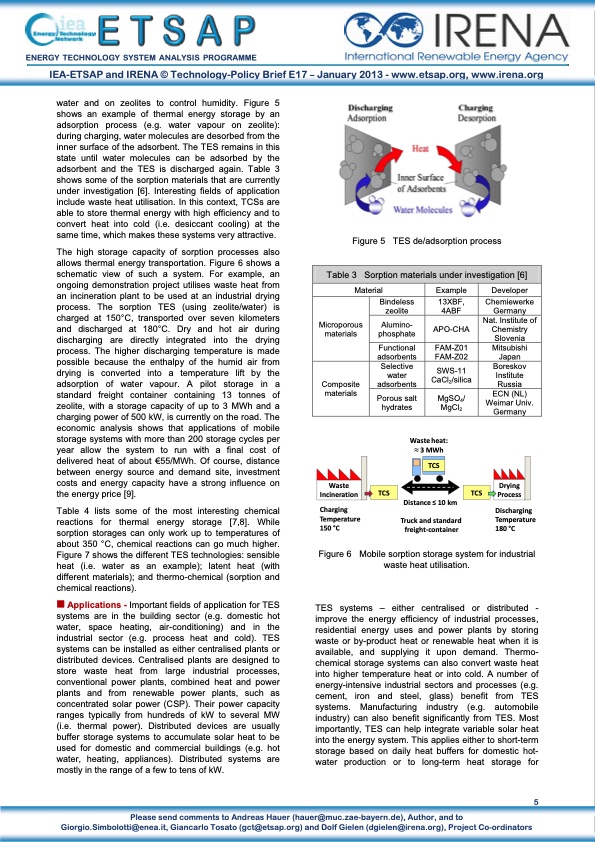

ENERGY TECHNOLOGY SYSTEM ANALYSIS PROGRAMME IEA-ETSAP and IRENA © Technology-Policy Brief E17 – January 2013 - www.etsap.org, www.irena.org water and on zeolites to control humidity. Figure 5 shows an example of thermal energy storage by an adsorption process (e.g. water vapour on zeolite): during charging, water molecules are desorbed from the inner surface of the adsorbent. The TES remains in this state until water molecules can be adsorbed by the adsorbent and the TES is discharged again. Table 3 shows some of the sorption materials that are currently under investigation [6]. Interesting fields of application include waste heat utilisation. In this context, TCSs are able to store thermal energy with high efficiency and to convert heat into cold (i.e. desiccant cooling) at the same time, which makes these systems very attractive. The high storage capacity of sorption processes also allows thermal energy transportation. Figure 6 shows a schematic view of such a system. For example, an ongoing demonstration project utilises waste heat from an incineration plant to be used at an industrial drying process. The sorption TES (using zeolite/water) is charged at 150°C, transported over seven kilometers and discharged at 180°C. Dry and hot air during discharging are directly integrated into the drying process. The higher discharging temperature is made possible because the enthalpy of the humid air from drying is converted into a temperature lift by the adsorption of water vapour. A pilot storage in a standard freight container containing 13 tonnes of zeolite, with a storage capacity of up to 3 MWh and a charging power of 500 kW, is currently on the road. The economic analysis shows that applications of mobile storage systems with more than 200 storage cycles per year allow the system to run with a final cost of delivered heat of about €55/MWh. Of course, distance between energy source and demand site, investment costs and energy capacity have a strong influence on the energy price [9]. Table 4 lists some of the most interesting chemical reactions for thermal energy storage [7,8]. While sorption storages can only work up to temperatures of about 350 °C, chemical reactions can go much higher. Figure 7 shows the different TES technologies: sensible heat (i.e. water as an example); latent heat (with different materials); and thermo-chemical (sorption and chemical reactions). Applications - Important fields of application for TES systems are in the building sector (e.g. domestic hot water, space heating, air-conditioning) and in the industrial sector (e.g. process heat and cold). TES systems can be installed as either centralised plants or distributed devices. Centralised plants are designed to store waste heat from large industrial processes, conventional power plants, combined heat and power plants and from renewable power plants, such as concentrated solar power (CSP). Their power capacity ranges typically from hundreds of kW to several MW (i.e. thermal power). Distributed devices are usually buffer storage systems to accumulate solar heat to be used for domestic and commercial buildings (e.g. hot water, heating, appliances). Distributed systems are mostly in the range of a few to tens of kW. Figure 5 TES de/adsorption process Table 3 Sorption materials under investigation [6] Material Example 13XBF, 4ABF APO-CHA FAM-Z01 FAM-Z02 SWS-11 CaCl2/silica Developer Chemiewerke Germany Nat. Institute of Chemistry Slovenia Mitsubishi Japan Boreskov Institute Russia ECN (NL) Weimar Univ. Germany Discharging Temperature 180 °C Microporous materials Composite materials Charging Temperature 150 °C Bindeless zeolite Alumino- phosphate Functional adsorbents Selective water adsorbents Porous salt MgSO4/ hydrates MgCl2 5 Giorgio.Simbolotti@enea.it, Giancarlo Tosato (gct@etsap.org) and Dolf Gielen (dgielen@irena.org), Project Co-ordinators Waste Incineration Figure 6 Mobile sorption storage system for industrial waste heat utilisation. TCS Waste heat: ≈ 3 MWh TCS Distance ≤ 10 km Truck and standard freight‐container TCS TES systems – either centralised or distributed - improve the energy efficiency of industrial processes, residential energy uses and power plants by storing waste or by-product heat or renewable heat when it is available, and supplying it upon demand. Thermo- chemical storage systems can also convert waste heat into higher temperature heat or into cold. A number of energy-intensive industrial sectors and processes (e.g. cement, iron and steel, glass) benefit from TES systems. Manufacturing industry (e.g. automobile industry) can also benefit significantly from TES. Most importantly, TES can help integrate variable solar heat into the energy system. This applies either to short-term storage based on daily heat buffers for domestic hot- water production or to long-term heat storage for Drying Process Please send comments to Andreas Hauer (hauer@muc.zae-bayern.de), Author, and toPDF Image | ENERGY TECHNOLOGY SYSTEM ANALYSIS

PDF Search Title:

ENERGY TECHNOLOGY SYSTEM ANALYSISOriginal File Name Searched:

E17IR-ThEnergy Stor_AH_Jan2013_final_GSOK.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Sand Battery Sand and Paraffin for TES Thermo Energy Storage More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |