PDF Publication Title:

Text from PDF Page: 006

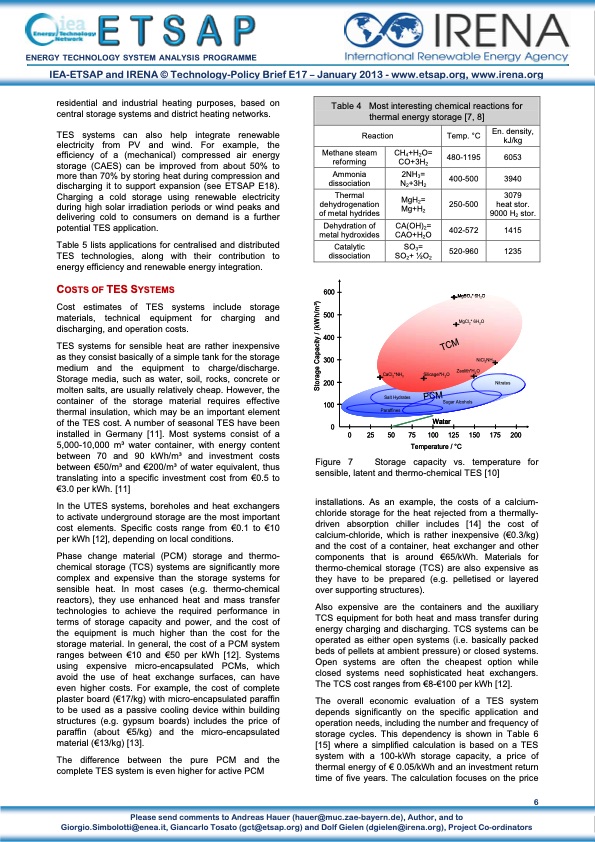

ENERGY TECHNOLOGY SYSTEM ANALYSIS PROGRAMME IEA-ETSAP and IRENA © Technology-Policy Brief E17 – January 2013 - www.etsap.org, www.irena.org residential and industrial heating purposes, based on central storage systems and district heating networks. TES systems can also help integrate renewable electricity from PV and wind. For example, the efficiency of a (mechanical) compressed air energy storage (CAES) can be improved from about 50% to more than 70% by storing heat during compression and discharging it to support expansion (see ETSAP E18). Charging a cold storage using renewable electricity during high solar irradiation periods or wind peaks and delivering cold to consumers on demand is a further potential TES application. Table 5 lists applications for centralised and distributed TES technologies, along with their contribution to energy efficiency and renewable energy integration. COSTS OF TES SYSTEMS Cost estimates of TES systems include storage materials, technical equipment for charging and discharging, and operation costs. TES systems for sensible heat are rather inexpensive as they consist basically of a simple tank for the storage medium and the equipment to charge/discharge. Storage media, such as water, soil, rocks, concrete or molten salts, are usually relatively cheap. However, the container of the storage material requires effective thermal insulation, which may be an important element of the TES cost. A number of seasonal TES have been installed in Germany [11]. Most systems consist of a 5,000-10,000 m3 water container, with energy content between 70 and 90 kWh/m3 and investment costs between €50/m3 and €200/m3 of water equivalent, thus translating into a specific investment cost from €0.5 to €3.0 per kWh. [11] In the UTES systems, boreholes and heat exchangers to activate underground storage are the most important cost elements. Specific costs range from €0.1 to €10 per kWh [12], depending on local conditions. Phase change material (PCM) storage and thermo- chemical storage (TCS) systems are significantly more complex and expensive than the storage systems for sensible heat. In most cases (e.g. thermo-chemical reactors), they use enhanced heat and mass transfer technologies to achieve the required performance in terms of storage capacity and power, and the cost of the equipment is much higher than the cost for the storage material. In general, the cost of a PCM system ranges between €10 and €50 per kWh [12]. Systems using expensive micro-encapsulated PCMs, which avoid the use of heat exchange surfaces, can have even higher costs. For example, the cost of complete plaster board (€17/kg) with micro-encapsulated paraffin to be used as a passive cooling device within building structures (e.g. gypsum boards) includes the price of paraffin (about €5/kg) and the micro-encapsulated material (€13/kg) [13]. The difference between the pure PCM and the complete TES system is even higher for active PCM Reaction Methane steam CH4+H2O= reforming CO+3H2 Temp. °C 480-1195 400-500 250-500 402-572 520-960 En. density, kJ/kg 6053 3940 3079 heat stor. 9000 H2 stor. Table 4 Most interesting chemical reactions for thermal energy storage [7, 8] Ammonia 2NH3= dissociation N2+3H2 Thermal MgH2= dehydrogenation Mg+H2 of metal hydrides Dehydration of CA(OH)2= metal hydroxides CAO+H2O Catalytic SO3= dissociation SO2+ 1⁄2O2 600 500 400 300 200 100 s 0 W 1415 1235 P P P s C H 3S 2O 2 C Ca S a aC Sa S s Sug s a a ar r r C C a a ra a a a f f f l l l2 f f f i i i * * * in n N N NH ne e e H S s s e e s S i i i l l l i i i c c ca a a g g g e e e l l l * * * H H OZ O g a ar r A M Mg Z Z Al e e e lc gS Mg o o o o SO4 oh Cl l l l i i it t t hol l2 h h h* l 4* 2* 6 * * * 6H2O H H O 6H H2 H2O N NH3 Ni O O M iCl l2 2 3 2 H 2O 2 3 3 2 2 N N N N N s i i i i i t t t t t r r r r r a a a a a t t t t te e e e e s s s s S s S a l l l lt t t t H H H H y y y d d d r r r ra a at t t te e W Wa a at t t e er r r 6 Giorgio.Simbolotti@enea.it, Giancarlo Tosato (gct@etsap.org) and Dolf Gielen (dgielen@irena.org), Project Co-ordinators 0 25 Figure 7 sensible, latent and thermo-chemical TES [10] installations. As an example, the costs of a calcium- chloride storage for the heat rejected from a thermally- driven absorption chiller includes [14] the cost of calcium-chloride, which is rather inexpensive (€0.3/kg) and the cost of a container, heat exchanger and other components that is around €65/kWh. Materials for thermo-chemical storage (TCS) are also expensive as they have to be prepared (e.g. pelletised or layered over supporting structures). Also expensive are the containers and the auxiliary TCS equipment for both heat and mass transfer during energy charging and discharging. TCS systems can be operated as either open systems (i.e. basically packed beds of pellets at ambient pressure) or closed systems. Open systems are often the cheapest option while closed systems need sophisticated heat exchangers. The TCS cost ranges from €8-€100 per kWh [12]. The overall economic evaluation of a TES system depends significantly on the specific application and operation needs, including the number and frequency of storage cycles. This dependency is shown in Table 6 [15] where a simplified calculation is based on a TES system with a 100-kWh storage capacity, a price of thermal energy of € 0.05/kWh and an investment return time of five years. The calculation focuses on the price 50 75 100 125 150 Temperature / °C 175 200 Storage capacity vs. temperature for Please send comments to Andreas Hauer (hauer@muc.zae-bayern.de), Author, and to TCM Storage Capacity / (kWh/m3) PCMPDF Image | ENERGY TECHNOLOGY SYSTEM ANALYSIS

PDF Search Title:

ENERGY TECHNOLOGY SYSTEM ANALYSISOriginal File Name Searched:

E17IR-ThEnergy Stor_AH_Jan2013_final_GSOK.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Sand Battery Sand and Paraffin for TES Thermo Energy Storage More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |