PDF Publication Title:

Text from PDF Page: 007

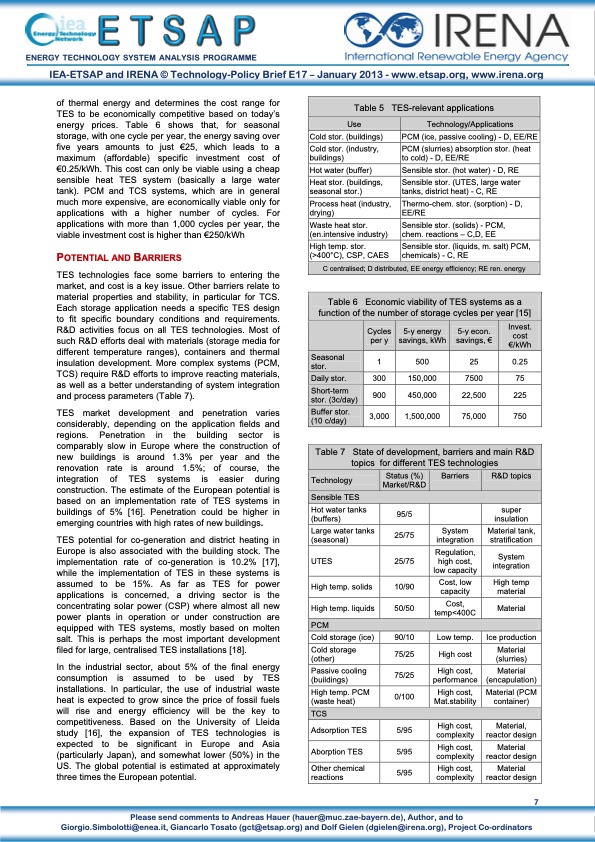

ENERGY TECHNOLOGY SYSTEM ANALYSIS PROGRAMME IEA-ETSAP and IRENA © Technology-Policy Brief E17 – January 2013 - www.etsap.org, www.irena.org Table 5 TES-relevant applications Use Technology/Applications of thermal energy and determines the cost range for TES to be economically competitive based on today’s energy prices. Table 6 shows that, for seasonal storage, with one cycle per year, the energy saving over five years amounts to just €25, which leads to a maximum (affordable) specific investment cost of €0.25/kWh. This cost can only be viable using a cheap sensible heat TES system (basically a large water tank). PCM and TCS systems, which are in general much more expensive, are economically viable only for applications with a higher number of cycles. For applications with more than 1,000 cycles per year, the viable investment cost is higher than €250/kWh POTENTIAL AND BARRIERS TES technologies face some barriers to entering the market, and cost is a key issue. Other barriers relate to material properties and stability, in particular for TCS. Each storage application needs a specific TES design to fit specific boundary conditions and requirements. R&D activities focus on all TES technologies. Most of such R&D efforts deal with materials (storage media for different temperature ranges), containers and thermal insulation development. More complex systems (PCM, TCS) require R&D efforts to improve reacting materials, as well as a better understanding of system integration and process parameters (Table 7). TES market development and penetration varies considerably, depending on the application fields and regions. Penetration in the building sector is comparably slow in Europe where the construction of new buildings is around 1.3% per year and the renovation rate is around 1.5%; of course, the integration of TES systems is easier during construction. The estimate of the European potential is based on an implementation rate of TES systems in buildings of 5% [16]. Penetration could be higher in emerging countries with high rates of new buildings. TES potential for co-generation and district heating in Europe is also associated with the building stock. The implementation rate of co-generation is 10.2% [17], while the implementation of TES in these systems is assumed to be 15%. As far as TES for power applications is concerned, a driving sector is the concentrating solar power (CSP) where almost all new power plants in operation or under construction are equipped with TES systems, mostly based on molten salt. This is perhaps the most important development filed for large, centralised TES installations [18]. In the industrial sector, about 5% of the final energy consumption is assumed to be used by TES installations. In particular, the use of industrial waste heat is expected to grow since the price of fossil fuels will rise and energy efficiency will be the key to competitiveness. Based on the University of Lleida study [16], the expansion of TES technologies is expected to be significant in Europe and Asia (particularly Japan), and somewhat lower (50%) in the US. The global potential is estimated at approximately three times the European potential. 7 Giorgio.Simbolotti@enea.it, Giancarlo Tosato (gct@etsap.org) and Dolf Gielen (dgielen@irena.org), Project Co-ordinators Cold stor. (buildings) Cold stor. (industry, buildings) Hot water (buffer) Heat stor. (buildings, seasonal stor.) Process heat (industry, drying) Waste heat stor. (en.intensive industry) High temp. stor. (>400°C), CSP, CAES PCM (ice, passive cooling) - D, EE/RE PCM (slurries) absorption stor. (heat to cold) - D, EE/RE Sensible stor. (hot water) - D, RE Sensible stor. (UTES, large water tanks, district heat) - C, RE Thermo-chem. stor. (sorption) - D, EE/RE Sensible stor. (solids) - PCM, chem. reactions – C,D, EE Sensible stor. (liquids, m. salt) PCM, chemicals) - C, RE C centralised; D distributed, EE energy efficiency; RE ren. energy 1 300 900 3,000 500 150,000 450,000 1,500,000 25 7500 22,500 75,000 5-y energy savings, kWh 5-y econ. savings, € Invest. cost €/kWh Seasonal stor. Daily stor. Short-term stor. (3c/day) Buffer stor. (10 c/day) Table 7 State of development, barriers and main R&D topics for different TES technologies Technology Status (%) Market/R&D Barriers R&D topics Sensible TES Hot water tanks 95/5 (buffers) Large water tanks 25/75 (seasonal) UTES 25/75 High temp. solids 10/90 High temp. liquids 50/50 PCM Cold storage (ice) 90/10 Cold storage 75/25 (other) Passive cooling 75/25 (buildings) High temp. PCM 0/100 (waste heat) TCS Adsorption TES 5/95 Aborption TES 5/95 Other chemical 5/95 reactions complexity 0.25 75 225 750 super insulation Material tank, stratification System integration High temp material Material Ice production Material (slurries) Material (encapulation) Material (PCM container) Material, reactor design Material reactor design Material reactor design System integration Regulation, high cost, low capacity Cost, low capacity Cost, temp<400C Low temp. High cost High cost, performance High cost, Mat.stability High cost, complexity High cost, complexity Please send comments to Andreas Hauer (hauer@muc.zae-bayern.de), Author, and to Table 6 Economic viability of TES systems as a function of the number of storage cycles per year [15] Cycles per y High cost,PDF Image | ENERGY TECHNOLOGY SYSTEM ANALYSIS

PDF Search Title:

ENERGY TECHNOLOGY SYSTEM ANALYSISOriginal File Name Searched:

E17IR-ThEnergy Stor_AH_Jan2013_final_GSOK.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Sand Battery Sand and Paraffin for TES Thermo Energy Storage More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |