PDF Publication Title:

Text from PDF Page: 007

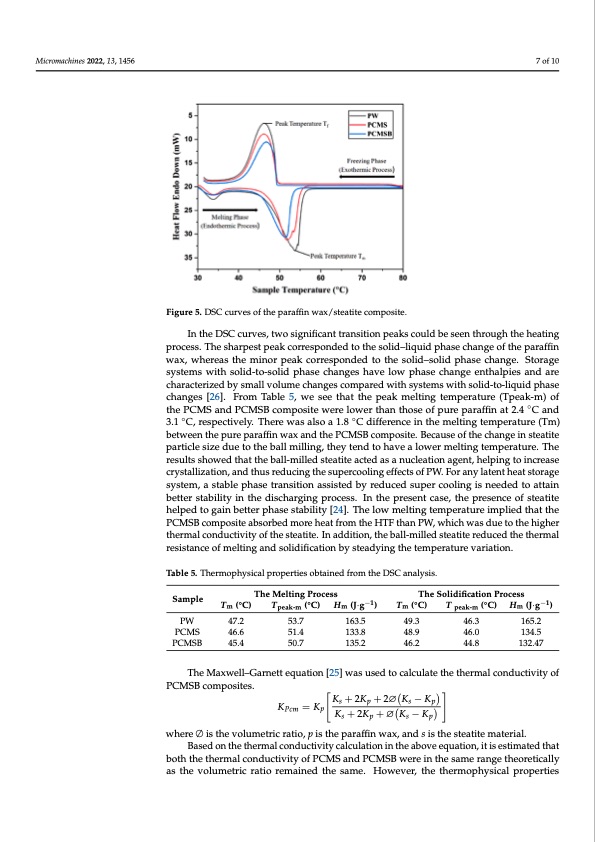

Micromachines 2022, 13, 1456 3.4. DSC Analysis A differential scanning calorimeter (DSC 6000, PerkinElmer, Inc., Waltham, MA, USA) was used to examine the thermal characteristics of the PW, PCMS, and PCMSB. During melting, a PCM composite sample was heated continuously from 30 °C to 80 °C 7 of 10 at a rate of 5 °C/min and then cooled back to 30 °C. Figure 5 shows the heating and cooling behavior curves of the paraffin wax and PCM/Steatite composites. Fiigurre5..DSCcurvesoffttheparafffifinwax/steatite composite. In the DSC curves, two significant transition peaks could be seen through the heating In the DSC curves, two significant transition peaks could be seen through the heating process. The sharpest peak corresponded to the solid–liquid phase change of the paraffin process. The sharpest peak corresponded to the solid–liquid phase change of the paraffin wax, whereas the minor peak corresponded to the solid–solid phase change. Storage wax, whereas the minor peak corresponded to the solid–solid phase change. Storage systems with solid-to-solid phase changes have low phase change enthalpies and are systems with solid-to-solid phase changes have low phase change enthalpies and are characterized by small volume changes compared with systems with solid-to-liquid phase characterized by small volume changes compared with systems with solid-to-liquid phase changes [26]. From Table 5, we see that the peak melting temperature (Tpeak-m) of changes [26]. From Table 5, we see that the peak melting temperature (Tpeak-m) of the the PCMS and PCMSB composite were lower than those of pure paraffin at 2.4 ◦C and PCMS and PCMSB composite were lower than those of pure paraffin at 2.4 °C and 3.1 °C, 3.1 ◦C, respectively. There was also a 1.8 ◦C difference in the melting temperature (Tm) respectively. There was also a 1.8 °C difference in the melting temperature (Tm) between between the pure paraffin wax and the PCMSB composite. Because of the change in steatite the pure paraffin wax and the PCMSB composite. Because of the change in steatite particle particle size due to the ball milling, they tend to have a lower melting temperature. The size due to the ball milling, they tend to have a lower melting temperature. The results results showed that the ball-milled steatite acted as a nucleation agent, helping to increase showed that the ball-milled steatite acted as a nucleation agent, helping to increase crystallization, and thus reducing the supercooling effects of PW. For any latent heat storage crystallization, and thus reducing the supercooling effects of PW. For any latent heat system, a stable phase transition assisted by reduced super cooling is needed to attain storage system, a stable phase transition assisted by reduced super cooling is needed to better stability in the discharging process. In the present case, the presence of steatite attain better stability in the discharging process. In the present case, the presence of helped to gain better phase stability [24]. The low melting temperature implied that the steatite helped to gain better phase stability [24]. The low melting temperature implied PCMSB composite absorbed more heat from the HTF than PW, which was due to the higher that the PCMSB composite absorbed more heat from the HTF than PW, which was due to thermal conductivity of the steatite. In addition, the ball-milled steatite reduced the thermal the higher thermal conductivity of the steatite. In addition, the ball-milled steatite reduced resistance of melting and solidification by steadying the temperature variation. the thermal resistance of melting and solidification by steadying the temperature variation. Table 5. Thermophysical properties obtained from the DSC analysis. Sample PW PCMS PCMSB The Melting Process The Solidification Process Tm (°C) 47.2 46.6 45.4 Tpeak-m (°C) 53.7 51.4 50.7 Hm (J·g−1) 163.5 133.8 135.2 Tm (°C) 49.3 48.9 46.2 T peak-m (°C) 46.3 46.0 44.8 Hm (J·g−1) 165.2 134.5 132.47 The Maxwell–Garnett equation [25] was used to calculate the thermal conductivity of PCMSB composites. Ks +2Kp +2∅Ks −Kp KPcm = Kp Ks +2Kp +∅Ks −Kp where ∅ is the volumetric ratio, p is the paraffin wax, and s is the steatite material. Based on the thermal conductivity calculation in the above equation, it is estimated that both the thermal conductivity of PCMS and PCMSB were in the same range theoretically as the volumetric ratio remained the same. However, the thermophysical propertiesPDF Image | Heat Charging–Discharging Periods of Paraffin Wax

PDF Search Title:

Heat Charging–Discharging Periods of Paraffin WaxOriginal File Name Searched:

micromachines-13-01456-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Sand Battery Sand and Paraffin for TES Thermo Energy Storage More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |