PDF Publication Title:

Text from PDF Page: 010

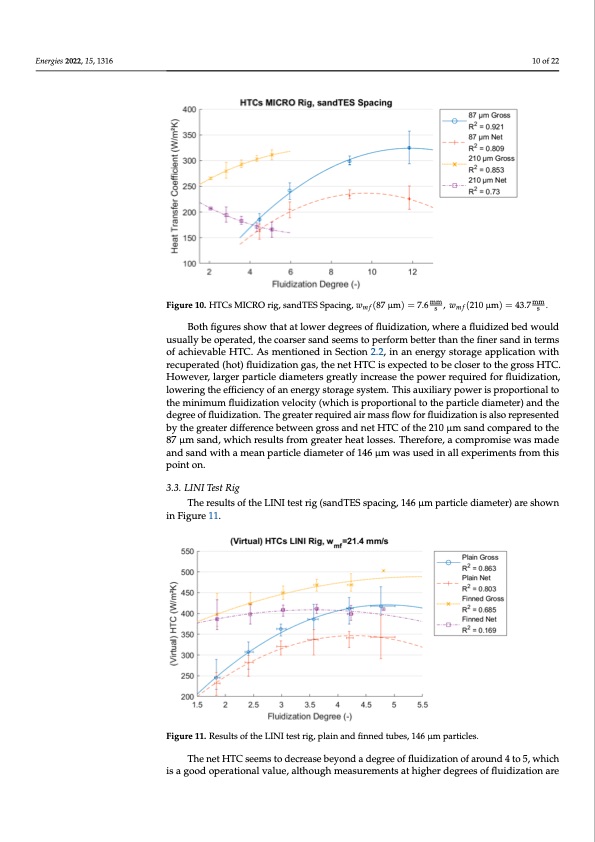

Energies 2022, 15, x FOR PEER REVIEW Energies 2022, 15, 1316 10 of 22 The heat losses appear to be greater than with the regular tube spacing, in particular usually be operated, the coarser sand seems to perform better than the finer sand in terms when using 210 μm sand, where the heat losses are disproportionate and the net HTC of achievable HTC. As mentioned in Section 2.2, in an energy storage application with decreases steadily. The net HTC of the 87 μm sand seems to decrease faster than with the recuperated (hot) fluidization gas, the net HTC is expected to be closer to the gross HTC. regular tube spacing shown in Figure 9 and has a maximum value at a lower degree of However, larger particle diameters greatly increase the power required for fluidization, fluidization. lowering the efficiency of an energy storage system. This auxiliary power is proportional to In comparison, the sandTES tube spacing performs consistently better than the the minimum fluidization velocity (which is proportional to the particle diameter) and the regular tube spacing within the limits of the measured degrees of fluidization. Therefore, degree of fluidization. The greater required air mass flow for fluidization is also represented the better performance of the sandTES tube spacing seems to be confirmed by the results by the greater difference between gross and net HTC of the 210 μm sand compared to the of these experiments. This is why it was decided to conduct experiments with the sandTES 87 μm sand, which results from greater heat losses. Therefore, a compromise was made tube spacing only from this point on. and sand with a mean particle diameter of 146 μm was used in all experiments from this Both figures show that at lower degrees of fluidization, where a fluidized bed would point on. usually be operated, the coarser sand seems to perform better than the finer sand in terms of achievable HTC. As mentioned in Section 2.2, in an energy storage application with 3.3. LINI Test Rig recuperated (hot) fluidization gas, the net HTC is expected to be closer to the gross HTC. Energies 2022, 15, x FOR PEER REVIEW 11 of 22 The results of the LINI test rig (sandTES spacing, 146 μm particle diameter) are shown However, larger particle diameters greatly increase the power required for fluidization, in Figure 11. lowering the efficiency of an energy storage system. This auxiliary power is proportional to the minimum fluidization velocity (which is proportional to the particle diameter) and the degree of fluidization. The greater required air mass flow for fluidization is also represented by the greater difference between gross and net HTC of the 210 μm sand compared to the 87 μm sand, which results from greater heat losses. Therefore, a compromise was made and sand with a mean particle diameter of 146 μm was used in all experiments from this point on. 3.3. LINI Test Rig The results of the LINI test rig (sandTES spacing, 146 μm particle diameter) are shown in Figure 11. Figure 11. Results of the LINI test rig, plain and finned tubes, 146 μm particles. Figure 11. Results of the LINI test rig, plain and finned tubes, 146 μm particles. ThTehennetetHTTCseems to decrreeaasseebbeeyyoonndda adedgergeereoef oflfuifdluizidatizioantionf aorof uanrodu4ntdo 54, twoh5ic, h wihsiachgoiosdaopgeoroadtionoaplevratliuoen,allthvoalugeh, malethasourgehmemntesasaut rheimgheenrtsdeagtrehesigohfeflrudideigzraeteiosnoafre fluidization are missing for a definitive conclusion. Compared to the MICRO experiments with 210 μm sand, the HTCs are slightly better, in particular the net HTC, which is not very surprising given the lower air mass flow required for the same degree of fluidization. One can see that the finned tubes perform better than the plain tubes, especially at lower degrees of fluidization. The difference between gross and net HTCs is slightly 10 of 22 Figure 10. HTCs MICRO rig, sandTES Spacing, 𝑤 (87 μ𝑚) = 7.6 mm, 𝑤 (210 μ𝑚) = 43.7 m.m Figure10.HTCsMICROrig,sandTESSpacing,w (87μm)=7.6 ,w (210μm)=43.7 . mf smf s Both figures show that at lower degrees of fluidization, where a fluidized bed would PDF Image | Heat Transfer between Finned Tubes

PDF Search Title:

Heat Transfer between Finned TubesOriginal File Name Searched:

energies-15-01316.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Sand Battery Sand and Paraffin for TES Thermo Energy Storage More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |