PDF Publication Title:

Text from PDF Page: 019

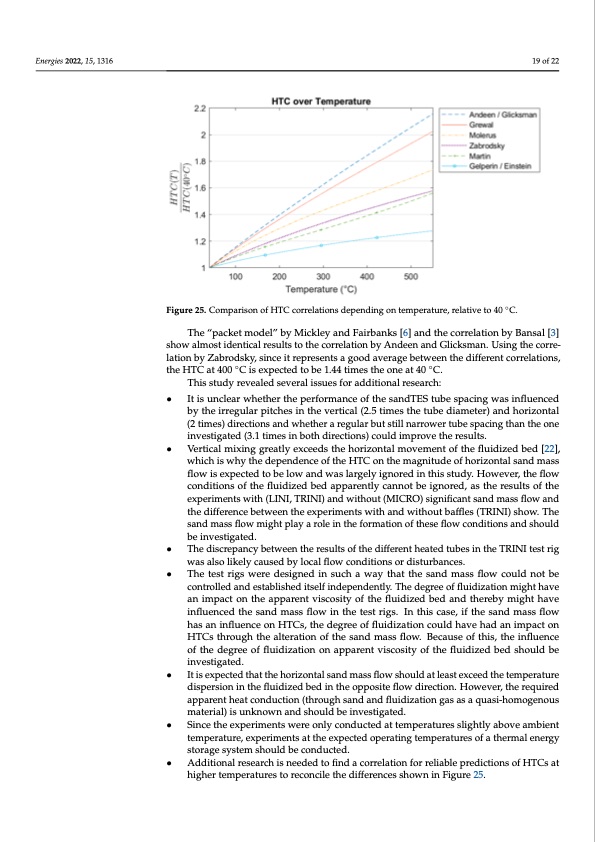

Energies 2022, 15, 1316 above ambient temperature (40 °C) was determined. In order to estimate the temperature dependence of the HTC, several of the aforementioned correlations were investigated in respect to their sensitivity to temperature changes, namely the ones by Andeen and Glicksman [2], Grewal [4], Molerus [5], Zabrodsky [20], Martin [7], and Gelperin and Einstein [21]. Unfortunately, there are great discrepancies between the pred1i9cotifo2n2 s, as shown in Figure 25. ◦ The “packet model” by Mickley and Fairbanks [6] and the correlation by Bansal [3] The “packet model” by Mickley and Fairbanks [6] and the correlation by Bansal [3] Figure 25. Comparison of HTC correlations depending on temperature, relative to 40 °C. Figure 25. Comparison of HTC correlations depending on temperature, relative to 40 C. show almost identical results to the correlation by Andeen and Glicksman. Using the corre- • This study revealed several issues for additional research: • The test rigs were designed in such a way that the sand mass flow could not be show almost identical results to the correlation by Andeen and Glicksman. Using the lation by Zabrodsky, since it represents a good average between the different correlations, correlation by Zabrodsky, since it represents a good average between the different the HTC at 400 ◦C is expected to be 1.44 times the one at 40 ◦C. correlations, the HTC at 400 °C is expected to be 1.44 times the one at 40 °C. • It is unclear whether the performance of the sandTES tube spacing was influenced • • • investigated (3.1 times in both directions) could improve the results. • The discrepancy between the results of the different heated tubes in the TRINI test • • • • The test rigs were designed in such a way that the sand mass flow could not be This study revealed several issues for additional research: It is unclear whether the performance of the sandTES tube spacing was influenced by the irregular pitches in the vertical (2.5 times the tube diameter) and horizontal by the irregular pitches in the vertical (2.5 times the tube diameter) and horizontal (2 (2 times) directions and whether a regular but still narrower tube spacing than the one times) directions and whether a regular but still narrower tube spacing than the one investigated (3.1 times in both directions) could improve the results. Vertical mixing greatly exceeds the horizontal movement of the fluidized bed [22], Vertical mixing greatly exceeds the horizontal movement of the fluidized bed [22], which is why the dependence of the HTC on the magnitude of horizontal sand mass which is why the dependence of the HTC on the magnitude of horizontal sand mass flow is expected to be low and was largely ignored in this study. However, the flow cfolnodwitisonesxpoefcttheedfltuoibdeizleodwbaenddapwpaasrelanrtglyelcyanignnootrbeediignntohriesds,tausdtyh.eHroeswueltvseor,f the flow ecxopnerdimitieontswofitthh(eLIfNluIi,dTiRzeINdIb)eadndawppitahroeuntt(lMyIcCaRnOno)tsibgeniifigcnaonrtesda,ndasmtahsesrfleoswulatsndofthe the difference between the experiments with and without baffles (TRINI) show. The experiments with (LINI, TRINI) and without (MICRO) significant sand mass flow sand mass flow might play a role in the formation of these flow conditions and should and the difference between the experiments with and without baffles (TRINI) show. be investigated. The sand mass flow might play a role in the formation of these flow conditions and The discrepancy between the results of the different heated tubes in the TRINI test rig should be investigated. was also likely caused by local flow conditions or disturbances. rig was also likely caused by local flow conditions or disturbances. controlled and established itself independently. The degree of fluidization might have an impact on the apparent viscosity of the fluidized bed and thereby might have controlled and established itself independently. The degree of fluidization might influenced the sand mass flow in the test rigs. In this case, if the sand mass flow has an influence on HTCs, the degree of fluidization could have had an impact on HTCs through the alteration of the sand mass flow. Because of this, the influence of the degree of fluidization on apparent viscosity of the fluidized bed should be investigated. It is expected that the horizontal sand mass flow should at least exceed the temperature dispersion in the fluidized bed in the opposite flow direction. However, the required apparent heat conduction (through sand and fluidization gas as a quasi-homogenous material) is unknown and should be investigated. Since the experiments were only conducted at temperatures slightly above ambient temperature, experiments at the expected operating temperatures of a thermal energy storage system should be conducted. Additional research is needed to find a correlation for reliable predictions of HTCs at higher temperatures to reconcile the differences shown in Figure 25.PDF Image | Heat Transfer between Finned Tubes

PDF Search Title:

Heat Transfer between Finned TubesOriginal File Name Searched:

energies-15-01316.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Sand Battery Sand and Paraffin for TES Thermo Energy Storage More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |