PDF Publication Title:

Text from PDF Page: 016

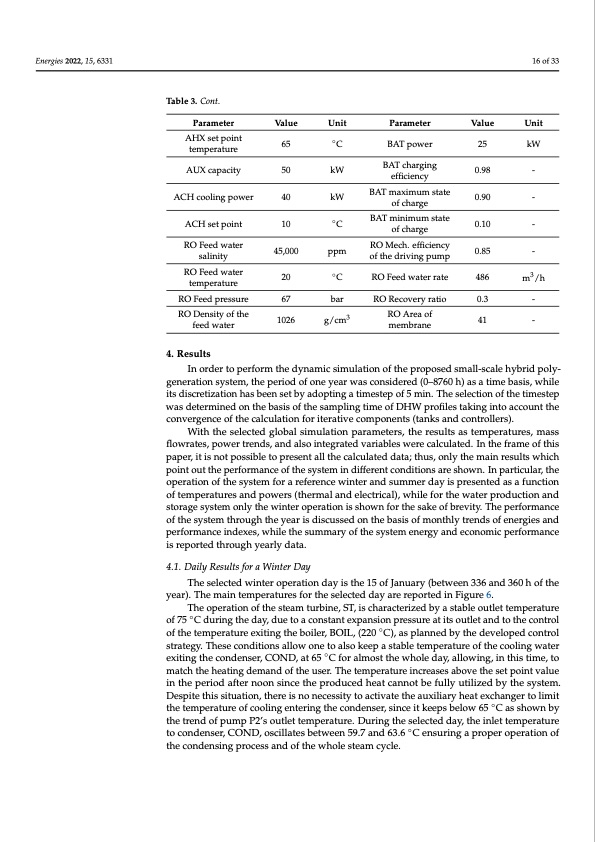

Energies 2022, 15, 6331 16 of 33 Table 3. Cont. Parameter AHX set point temperature AUX capacity ACH cooling power ACH set point RO Feed water salinity RO Feed water temperature RO Feed pressure RO Density of the feed water 4. Results Value Unit 65 ◦C 50 kW 40 kW 10 ◦C 45,000 ppm 20 ◦C 67 bar 1026 g/cm3 Parameter BAT power BAT charging efficiency BAT maximum state of charge BAT minimum state of charge RO Mech. efficiency of the driving pump RO Feed water rate RO Recovery ratio RO Area of membrane Value Unit 25 kW 0.98 - 0.90 - 0.10 - 0.85 - 486 m3/h 0.3 - 41 - In order to perform the dynamic simulation of the proposed small-scale hybrid poly- generation system, the period of one year was considered (0–8760 h) as a time basis, while its discretization has been set by adopting a timestep of 5 min. The selection of the timestep was determined on the basis of the sampling time of DHW profiles taking into account the convergence of the calculation for iterative components (tanks and controllers). With the selected global simulation parameters, the results as temperatures, mass flowrates, power trends, and also integrated variables were calculated. In the frame of this paper, it is not possible to present all the calculated data; thus, only the main results which point out the performance of the system in different conditions are shown. In particular, the operation of the system for a reference winter and summer day is presented as a function of temperatures and powers (thermal and electrical), while for the water production and storage system only the winter operation is shown for the sake of brevity. The performance of the system through the year is discussed on the basis of monthly trends of energies and performance indexes, while the summary of the system energy and economic performance is reported through yearly data. 4.1. Daily Results for a Winter Day The selected winter operation day is the 15 of January (between 336 and 360 h of the year). The main temperatures for the selected day are reported in Figure 6. The operation of the steam turbine, ST, is characterized by a stable outlet temperature of 75 ◦C during the day, due to a constant expansion pressure at its outlet and to the control of the temperature exiting the boiler, BOIL, (220 ◦C), as planned by the developed control strategy. These conditions allow one to also keep a stable temperature of the cooling water exiting the condenser, COND, at 65 ◦C for almost the whole day, allowing, in this time, to match the heating demand of the user. The temperature increases above the set point value in the period after noon since the produced heat cannot be fully utilized by the system. Despite this situation, there is no necessity to activate the auxiliary heat exchanger to limit the temperature of cooling entering the condenser, since it keeps below 65 ◦C as shown by the trend of pump P2’s outlet temperature. During the selected day, the inlet temperature to condenser, COND, oscillates between 59.7 and 63.6 ◦C ensuring a proper operation of the condensing process and of the whole steam cycle.PDF Image | Hybrid Polygeneration System Based on Biomass Wind and Solar Energy

PDF Search Title:

Hybrid Polygeneration System Based on Biomass Wind and Solar EnergyOriginal File Name Searched:

energies-15-06331-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Sand Battery Sand and Paraffin for TES Thermo Energy Storage More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |