PDF Publication Title:

Text from PDF Page: 020

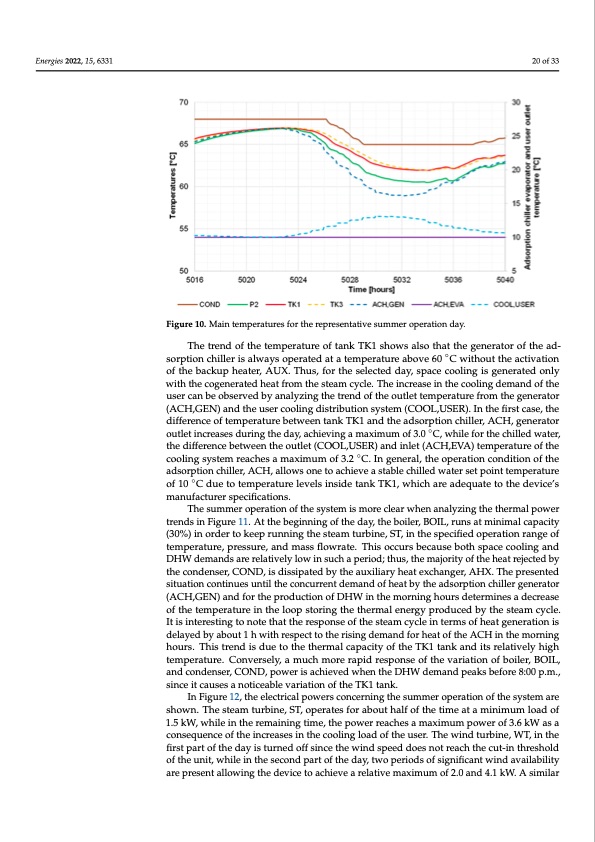

tem can be observed starting from the maximum of 67 °C. TK1 tank temperatur o n n x v n e c e l d a c r T n e d s h Energies 2022, 15, 6331 below 65 °C before 11:00 am, and one hour earlier, the same occurs for the outlet P2, which determines the end of the necessity of cooling down the water returni condenser, COND, by the auxiliary heat exchanger, AHX. As occurred in the wi here, also, TK3 tank temperature follows that of TK1 due to continuous heat e between the tanks. Figure 10. Main temperatures for the representative summer operation day. Figure 10. Main temperatures for the representative summer operation day. of the backup heater, AUX. Thus, for the selected day, space cooling is generated only sorption chiller is always operated at a temperature above 60 °C without the acti with the cogenerated heat from the steam cycle. The increase in the cooling demand of the the backup heater, AUX. Thus, for the selected day, space cooling is generated o user can be observed by analyzing the trend of the outlet temperature from the generator (tAheCHco,GgEeNne) raantdetdhehuesaetrfcroomlintghdeisttreibaumtiocnyscylset.eTmh(eCOinOcLre,UaSsEeRin). Itnhtehceofiorslitncgased,ethmeand of difference of temperature between tank TK1 and the adsorption chiller, ACH, generator 20 of 33 The trend of the temperature of tank TK1 shows also that the generator of the ad- sorption chiller is always operated at a temperature above 60 ◦C without the activation The trend of the temperature of tank TK1 shows also that the generator of can be observed by analyzing the trend of the outlet temperature from the g outlet increases during the day, achieving a maximum of 3.0 ◦C, while for the chilled water, (ACH,GEN) and the user cooling distribution system (COOL,USER). In the first the difference between the outlet (COOL,USER) and inlet (ACH,EVA) temperature of the difference of temperature between t◦ank TK1 and the adsorption chiller, ACH, g cooling system reaches a maximum of 3.2 C. In general, the operation condition of the outlet increases during the day, achieving a maximum of 3.0 °C, while for the chi adsorption chiller, ACH, allows one to achieve a stable chilled water set point temperature ◦ ter, the difference between the outlet (COOL,USER) and inlet (ACH,EVA) temper of 10 C due to temperature levels inside tank TK1, which are adequate to the device’s manufacturer specifications. the cooling system reaches a maximum of 3.2 °C. In general, the operation con The summer operation of the system is more clear when analyzing the thermal power the adsorption chiller, ACH, allows one to achieve a stable chilled water set point trends in Figure 11. At the beginning of the day, the boiler, BOIL, runs at minimal capacity ature of 10 °C due to temperature levels inside tank TK1, which are adequate to (30%) in order to keep running the steam turbine, ST, in the specified operation range of vteimcep’esramtuarne,upfraecstsure,rasnpdemciafiscsafltoiownrsa.te. This occurs because both space cooling and DHW demands are relatively low in such a period; thus, the majority of the heat rejected by The summer operation of the system is more clear when analyzing the therm the condenser, COND, is dissipated by the auxiliary heat exchanger, AHX. The presented trends in Figure 11. At the beginning of the day, the boiler, BOIL, runs at minimal situation continues until the concurrent demand of heat by the adsorption chiller generator (30%) in order to keep running the steam turbine, ST, in the specified operation (ACH,GEN) and for the production of DHW in the morning hours determines a decrease toefmthpeetermatpuerea,tuprereinsstuhreel,ooapndstomrinagssthfelothwermatael.eTnehrigsyopcrocudurscebdebcyatuhseestbeoamthcsypclae.ce cool It is interesting to note that the response of the steam cycle in terms of heat generation is DHW demands are relatively low in such a period; thus, the majority of the heat delayed by about 1 h with respect to the rising demand for heat of the ACH in the morning by the condenser, COND, is dissipated by the auxiliary heat exchanger, AHX. hours. This trend is due to the thermal capacity of the TK1 tank and its relatively high sented situation continues until the concurrent demand of heat by the adsorptio temperature. Conversely, a much more rapid response of the variation of boiler, BOIL, generator (ACH,GEN) and for the production of DHW in the morning hours det and condenser, COND, power is achieved when the DHW demand peaks before 8:00 p.m., asindcecitrceaussesoafntohtiecetaebmlepveariatuiorneofinthethTeK1lotoanpk.storing the thermal energy produce In Figure 12, the electrical powers concerning the summer operation of the system are steam cycle. It is interesting to note that the response of the steam cycle in term shown. The steam turbine, ST, operates for about half of the time at a minimum load of generation is delayed by about 1 h with respect to the rising demand for heat of t 1.5 kW, while in the remaining time, the power reaches a maximum power of 3.6 kW as a consequence of the increases in the cooling load of the user. The wind turbine, WT, in the first part of the day is turned off since the wind speed does not reach the cut-in threshold of the unit, while in the second part of the day, two periods of significant wind availability are present allowing the device to achieve a relative maximum of 2.0 and 4.1 kW. A similarPDF Image | Hybrid Polygeneration System Based on Biomass Wind and Solar Energy

PDF Search Title:

Hybrid Polygeneration System Based on Biomass Wind and Solar EnergyOriginal File Name Searched:

energies-15-06331-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Sand Battery Sand and Paraffin for TES Thermo Energy Storage More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |