PDF Publication Title:

Text from PDF Page: 006

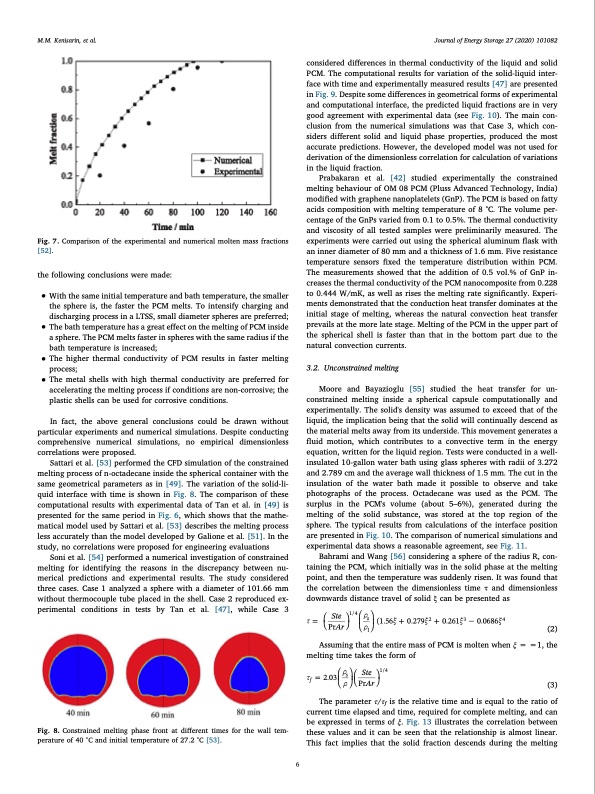

M.M. Kenisarin, et al. Journal of Energy Storage 27 (2020) 101082 considered differences in thermal conductivity of the liquid and solid PCM. The computational results for variation of the solid-liquid inter- face with time and experimentally measured results [47] are presented in Fig. 9. Despite some differences in geometrical forms of experimental and computational interface, the predicted liquid fractions are in very good agreement with experimental data (see Fig. 10). The main con- clusion from the numerical simulations was that Case 3, which con- siders different solid and liquid phase properties, produced the most accurate predictions. However, the developed model was not used for derivation of the dimensionless correlation for calculation of variations in the liquid fraction. Prabakaran et al. [42] studied experimentally the constrained melting behaviour of OM 08 PCM (Pluss Advanced Technology, India) modified with graphene nanoplatelets (GnP). The PCM is based on fatty acids composition with melting temperature of 8 °C. The volume per- centage of the GnPs varied from 0.1 to 0.5%. The thermal conductivity and viscosity of all tested samples were preliminarily measured. The experiments were carried out using the spherical aluminum flask with an inner diameter of 80 mm and a thickness of 1.6 mm. Five resistance temperature sensors fixed the temperature distribution within PCM. The measurements showed that the addition of 0.5 vol.% of GnP in- creases the thermal conductivity of the PCM nanocomposite from 0.228 to 0.444 W/mK, as well as rises the melting rate significantly. Experi- ments demonstrated that the conduction heat transfer dominates at the initial stage of melting, whereas the natural convection heat transfer prevails at the more late stage. Melting of the PCM in the upper part of the spherical shell is faster than that in the bottom part due to the natural convection currents. 3.2. Unconstrained melting Moore and Bayazioglu [55] studied the heat transfer for un- constrained melting inside a spherical capsule computationally and experimentally. The solid's density was assumed to exceed that of the liquid, the implication being that the solid will continually descend as the material melts away from its underside. This movement generates a fluid motion, which contributes to a convective term in the energy equation, written for the liquid region. Tests were conducted in a well- insulated 10-gallon water bath using glass spheres with radii of 3.272 and 2.789 cm and the average wall thickness of 1.5 mm. The cut in the insulation of the water bath made it possible to observe and take photographs of the process. Octadecane was used as the PCM. The surplus in the PCM's volume (about 5–6%), generated during the melting of the solid substance, was stored at the top region of the sphere. The typical results from calculations of the interface position are presented in Fig. 10. The comparison of numerical simulations and experimental data shows a reasonable agreement, see Fig. 11. Bahrami and Wang [56] considering a sphere of the radius R, con- taining the PCM, which initially was in the solid phase at the melting point, and then the temperature was suddenly risen. It was found that the correlation between the dimensionless time τ and dimensionless downwards distance travel of solid ξ can be presented as = Ste 1/4 s (1.56 +0.279 2 +0.261 3 0.0686 4 Fig. 7. Comparison of the experimental and numerical molten mass fractions [52]. the following conclusions were made: • With the same initial temperature and bath temperature, the smaller the sphere is, the faster the PCM melts. To intensify charging and • discharging process in a LTSS, small diameter spheres are preferred; The bath temperature has a great effect on the melting of PCM inside a sphere. The PCM melts faster in spheres with the same radius if the • bath temperature is increased; The higher thermal conductivity of PCM results in faster melting • process; The metal shells with high thermal conductivity are preferred for accelerating the melting process if conditions are non-corrosive; the plastic shells can be used for corrosive conditions. In fact, the above general conclusions could be drawn without particular experiments and numerical simulations. Despite conducting comprehensive numerical simulations, no empirical dimensionless correlations were proposed. Sattari et al. [53] performed the CFD simulation of the constrained melting process of n-octadecane inside the spherical container with the same geometrical parameters as in [49]. The variation of the solid-li- quid interface with time is shown in Fig. 8. The comparison of these computational results with experimental data of Tan et al. in [49] is presented for the same period in Fig. 6, which shows that the mathe- matical model used by Sattari et al. [53] describes the melting process less accurately than the model developed by Galione et al. [51]. In the study, no correlations were proposed for engineering evaluations Soni et al. [54] performed a numerical investigation of constrained melting for identifying the reasons in the discrepancy between nu- merical predictions and experimental results. The study considered three cases. Case 1 analyzed a sphere with a diameter of 101.66 mm without thermocouple tube placed in the shell. Case 2 reproduced ex- perimental conditions in tests by Tan et al. [47], while Case 3 Fig. 8. Constrained melting phase front at different times for the wall tem- perature of 40 °C and initial temperature of 27.2 °C [53]. l (2) melting time takes the form of PrAr Assuming that the entire mass of PCM is molten when ξ = =1, the 6 f=2.03 s Ste 1/4 PrAr (3) The parameter τ/τf is the relative time and is equal to the ratio of current time elapsed and time, required for complete melting, and can be expressed in terms of ξ. Fig. 13 illustrates the correlation between these values and it can be seen that the relationship is almost linear. This fact implies that the solid fraction descends during the meltingPDF Image | Journal of Energy Storage 27

PDF Search Title:

Journal of Energy Storage 27Original File Name Searched:

tes-spherical-ball-storage-paraffin.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Sand Battery Sand and Paraffin for TES Thermo Energy Storage More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |