PDF Publication Title:

Text from PDF Page: 011

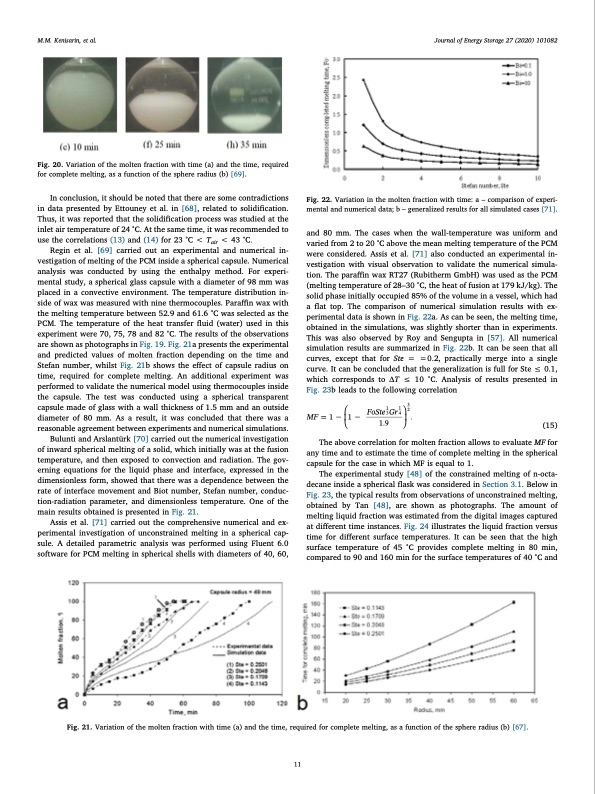

M.M. Kenisarin, et al. Journal of Energy Storage 27 (2020) 101082 Fig. 20. Variation of the molten fraction with time (a) and the time, required for complete melting, as a function of the sphere radius (b) [69]. In conclusion, it should be noted that there are some contradictions in data presented by Ettouney et al. in [68], related to solidification. Thus, it was reported that the solidification process was studied at the inlet air temperature of 24 °C. At the same time, it was recommended to use the correlations (13) and (14) for 23 °C < Tair < 43 °C. Regin et al. [69] carried out an experimental and numerical in- vestigation of melting of the PCM inside a spherical capsule. Numerical analysis was conducted by using the enthalpy method. For experi- mental study, a spherical glass capsule with a diameter of 98 mm was placed in a convective environment. The temperature distribution in- side of wax was measured with nine thermocouples. Paraffin wax with the melting temperature between 52.9 and 61.6 °C was selected as the PCM. The temperature of the heat transfer fluid (water) used in this experiment were 70, 75, 78 and 82 °C. The results of the observations are shown as photographs in Fig. 19. Fig. 21a presents the experimental and predicted values of molten fraction depending on the time and Stefan number, whilst Fig. 21b shows the effect of capsule radius on time, required for complete melting. An additional experiment was performed to validate the numerical model using thermocouples inside the capsule. The test was conducted using a spherical transparent capsule made of glass with a wall thickness of 1.5 mm and an outside diameter of 80 mm. As a result, it was concluded that there was a reasonable agreement between experiments and numerical simulations. Bulunti and Arslantürk [70] carried out the numerical investigation of inward spherical melting of a solid, which initially was at the fusion temperature, and then exposed to convection and radiation. The gov- erning equations for the liquid phase and interface, expressed in the dimensionless form, showed that there was a dependence between the rate of interface movement and Biot number, Stefan number, conduc- tion-radiation parameter, and dimensionless temperature. One of the main results obtained is presented in Fig. 21. Assis et al. [71] carried out the comprehensive numerical and ex- perimental investigation of unconstrained melting in a spherical cap- sule. A detailed parametric analysis was performed using Fluent 6.0 software for PCM melting in spherical shells with diameters of 40, 60, Fig. 22. Variation in the molten fraction with time: a – comparison of experi- mental and numerical data; b – generalized results for all simulated cases [71]. and 80 mm. The cases when the wall-temperature was uniform and varied from 2 to 20 °C above the mean melting temperature of the PCM were considered. Assis et al. [71] also conducted an experimental in- vestigation with visual observation to validate the numerical simula- tion. The paraffin wax RT27 (Rubitherm GmbH) was used as the PCM (melting temperature of 28–30 °C, the heat of fusion at 179 kJ/kg). The solid phase initially occupied 85% of the volume in a vessel, which had a flat top. The comparison of numerical simulation results with ex- perimental data is shown in Fig. 22a. As can be seen, the melting time, obtained in the simulations, was slightly shorter than in experiments. This was also observed by Roy and Sengupta in [57]. All numerical simulation results are summarized in Fig. 22b. It can be seen that all curves, except that for Ste = =0.2, practically merge into a single curve. It can be concluded that the generalization is full for Ste ≤ 0.1, which corresponds to ΔT ≤ 10 °C. Analysis of results presented in Fig. 23b leads to the following correlation MF = 1 1 1 1 32 FoSte3Gr4 . 1.9 (15) The above correlation for molten fraction allows to evaluate MF for any time and to estimate the time of complete melting in the spherical capsule for the case in which MF is equal to 1. The experimental study [48] of the constrained melting of n-octa- decane inside a spherical flask was considered in Section 3.1. Below in Fig. 23, the typical results from observations of unconstrained melting, obtained by Tan [48], are shown as photographs. The amount of melting liquid fraction was estimated from the digital images captured at different time instances. Fig. 24 illustrates the liquid fraction versus time for different surface temperatures. It can be seen that the high surface temperature of 45 °C provides complete melting in 80 min, compared to 90 and 160 min for the surface temperatures of 40 °C and Fig. 21. Variation of the molten fraction with time (a) and the time, required for complete melting, as a function of the sphere radius (b) [67]. 11PDF Image | Journal of Energy Storage 27

PDF Search Title:

Journal of Energy Storage 27Original File Name Searched:

tes-spherical-ball-storage-paraffin.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Sand Battery Sand and Paraffin for TES Thermo Energy Storage More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |