PDF Publication Title:

Text from PDF Page: 012

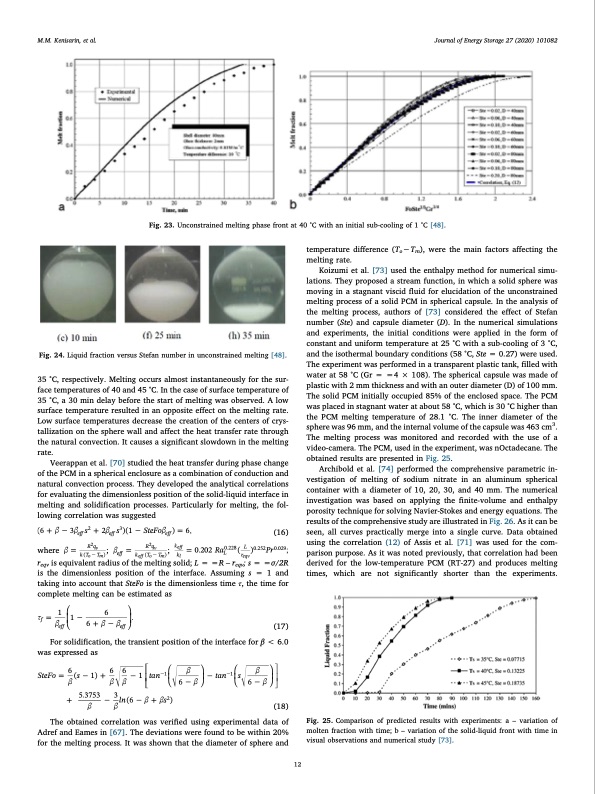

M.M. Kenisarin, et al. Journal of Energy Storage 27 (2020) 101082 Fig. 23. Unconstrained melting phase front Fig. 24. Liquid fraction versus Stefan number in unconstrained melting [48]. 35 °C, respectively. Melting occurs almost instantaneously for the sur- face temperatures of 40 and 45 °C. In the case of surface temperature of 35 °C, a 30 min delay before the start of melting was observed. A low surface temperature resulted in an opposite effect on the melting rate. Low surface temperatures decrease the creation of the centers of crys- tallization on the sphere wall and affect the heat transfer rate through the natural convection. It causes a significant slowdown in the melting rate. Veerappan et al. [70] studied the heat transfer during phase change of the PCM in a spherical enclosure as a combination of conduction and natural convection process. They developed the analytical correlations for evaluating the dimensionless position of the solid-liquid interface in melting and solidification processes. Particularly for melting, the fol- lowing correlation was suggested at 40 °C with an initial sub-cooling of 1 °C [48]. temperature difference (To−Tm), were the main factors affecting the melting rate. Koizumi et al. [73] used the enthalpy method for numerical simu- lations. They proposed a stream function, in which a solid sphere was moving in a stagnant viscid fluid for elucidation of the unconstrained melting process of a solid PCM in spherical capsule. In the analysis of the melting process, authors of [73] considered the effect of Stefan number (Ste) and capsule diameter (D). In the numerical simulations and experiments, the initial conditions were applied in the form of constant and uniform temperature at 25 °C with a sub-cooling of 3 °C, and the isothermal boundary conditions (58 °C, Ste = 0.27) were used. The experiment was performed in a transparent plastic tank, filled with water at 58 °C (Gr = =4 × 108). The spherical capsule was made of plastic with 2 mm thickness and with an outer diameter (D) of 100 mm. The solid PCM initially occupied 85% of the enclosed space. The PCM was placed in stagnant water at about 58 °C, which is 30 °C higher than the PCM melting temperature of 28.1 °C. The inner diameter of the sphere was 96 mm, and the internal volume of the capsule was 463 cm3. The melting process was monitored and recorded with the use of a video-camera. The PCM, used in the experiment, was nOctadecane. The obtained results are presented in Fig. 25. Archibold et al. [74] performed the comprehensive parametric in- vestigation of melting of sodium nitrate in an aluminum spherical container with a diameter of 10, 20, 30, and 40 mm. The numerical investigation was based on applying the finite-volume and enthalpy porosity technique for solving Navier-Stokes and energy equations. The results of the comprehensive study are illustrated in Fig. 26. As it can be seen, all curves practically merge into a single curve. Data obtained using the correlation (12) of Assis et al. [71] was used for the com- parison purpose. As it was noted previously, that correlation had been derived for the low-temperature PCM (RT-27) and produces melting times, which are not significantly shorter than the experiments. Fig. 25. Comparison of predicted results with experiments: a – variation of molten fraction with time; b – variation of the solid-liquid front with time in visual observations and numerical study [73]. (6+ 3 effs2 +2 effs3)(1 = SteFo eff)=6, (16) R2qv ; keff = 0.202 Ra0.228 ( L )0.252Pr0.029; where = R2qv ; k(To Tm) keff (To Tm) kl L reqv is equivalent radius of the melting solid; L = =R – reqv; s = =σ/2R is the dimensionless position of the interface. Assuming s = 1 and taking into account that SteFo is the dimensionless time τ, the time for eff reqv f=116. eff 6+ eff (17) For solidification, the transient position of the interface for β < 6.0 was expressed as complete melting can be estimated as SteFo=6(s 1)+6 6 1 tan1 + 5.3753 3ln(6 + s2) tan1 s 66 (18) The obtained correlation was verified using experimental data of Adref and Eames in [67]. The deviations were found to be within 20% for the melting process. It was shown that the diameter of sphere and 12PDF Image | Journal of Energy Storage 27

PDF Search Title:

Journal of Energy Storage 27Original File Name Searched:

tes-spherical-ball-storage-paraffin.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Sand Battery Sand and Paraffin for TES Thermo Energy Storage More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |