PDF Publication Title:

Text from PDF Page: 020

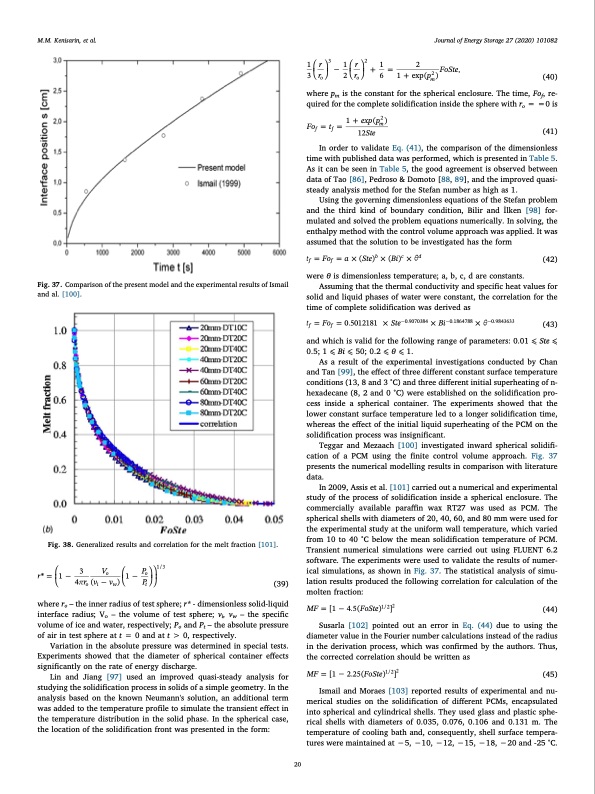

M.M. Kenisarin, et al. Journal of Energy Storage 27 (2020) 101082 1r31r212 + = 2 FoSte, 3 ro 2 ro 6 1+exp(pm) (40) where pm is the constant for the spherical enclosure. The time, Fof, re- quired for the complete solidification inside the sphere with ro = =0 is F o f = t f = 1 + e x p ( p m2 ) 12Ste (41) Fig. 37. Comparison of the present model and the experimental results of Ismail and al. [100]. Fig. 38. Generalized results and correlation for the melt fraction [101]. In order to validate Eq. (41), the comparison of the dimensionless time with published data was performed, which is presented in Table 5. As it can be seen in Table 5, the good agreement is observed between data of Tao [86], Pedroso & Domoto [88, 89], and the improved quasi- steady analysis method for the Stefan number as high as 1. Using the governing dimensionless equations of the Stefan problem and the third kind of boundary condition, Bilir and İlken [98] for- mulated and solved the problem equations numerically. In solving, the enthalpy method with the control volume approach was applied. It was assumed that the solution to be investigated has the form tf =Fof =a×(Ste)b ×(Bi)c × d (42) were θ is dimensionless temperature; a, b, c, d are constants. Assuming that the thermal conductivity and specific heat values for solid and liquid phases of water were constant, the correlation for the time of complete solidification was derived as tf = Fof = 0.5012181 × Ste 0.9070384 × Bi 0.1864788 × 0.9843633 (43) and which is valid for the following range of parameters: 0.01 ⩽ Ste ⩽ 0.5; 1 ⩽ Bi ⩽ 50; 0.2 ⩽ θ ⩽ 1. As a result of the experimental investigations conducted by Chan and Tan [99], the effect of three different constant surface temperature conditions (13, 8 and 3 °C) and three different initial superheating of n- hexadecane (8, 2 and 0 °C) were established on the solidification pro- cess inside a spherical container. The experiments showed that the lower constant surface temperature led to a longer solidification time, whereas the effect of the initial liquid superheating of the PCM on the solidification process was insignificant. Teggar and Mezaach [100] investigated inward spherical solidifi- cation of a PCM using the finite control volume approach. Fig. 37 presents the numerical modelling results in comparison with literature data. In 2009, Assis et al. [101] carried out a numerical and experimental study of the process of solidification inside a spherical enclosure. The commercially available paraffin wax RT27 was used as PCM. The spherical shells with diameters of 20, 40, 60, and 80 mm were used for the experimental study at the uniform wall temperature, which varied from 10 to 40 °C below the mean solidification temperature of PCM. Transient numerical simulations were carried out using FLUENT 6.2 software. The experiments were used to validate the results of numer- ical simulations, as shown in Fig. 37. The statistical analysis of simu- lation results produced the following correlation for calculation of the molten fraction: MF = [1 4.5(FoSte)1/2]2 (44) Susarla [102] pointed out an error in Eq. (44) due to using the diameter value in the Fourier number calculations instead of the radius in the derivation process, which was confirmed by the authors. Thus, the corrected correlation should be written as MF = [1 2.25(FoSte)1/2]2 (45) Ismail and Moraes [103] reported results of experimental and nu- merical studies on the solidification of different PCMs, encapsulated into spherical and cylindrical shells. They used glass and plastic sphe- rical shells with diameters of 0.035, 0.076, 0.106 and 0.131 m. The temperature of cooling bath and, consequently, shell surface tempera- tures were maintained at −5, −10, −12, −15, −18, −20 and -25 °C. 3VP r*=1 o1o 1/3 4r(vv) P oiw t (39) where ro – the inner radius of test sphere; r* - dimensionless solid-liquid interface radius; Vo – the volume of test sphere; vi, vw – the specific volume of ice and water, respectively; Po and Pt – the absolute pressure of air in test sphere at t = 0 and at t > 0, respectively. Variation in the absolute pressure was determined in special tests. Experiments showed that the diameter of spherical container effects significantly on the rate of energy discharge. Lin and Jiang [97] used an improved quasi-steady analysis for studying the solidification process in solids of a simple geometry. In the analysis based on the known Neumann's solution, an additional term was added to the temperature profile to simulate the transient effect in the temperature distribution in the solid phase. In the spherical case, the location of the solidification front was presented in the form: 20PDF Image | Journal of Energy Storage 27

PDF Search Title:

Journal of Energy Storage 27Original File Name Searched:

tes-spherical-ball-storage-paraffin.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Sand Battery Sand and Paraffin for TES Thermo Energy Storage More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |