PDF Publication Title:

Text from PDF Page: 025

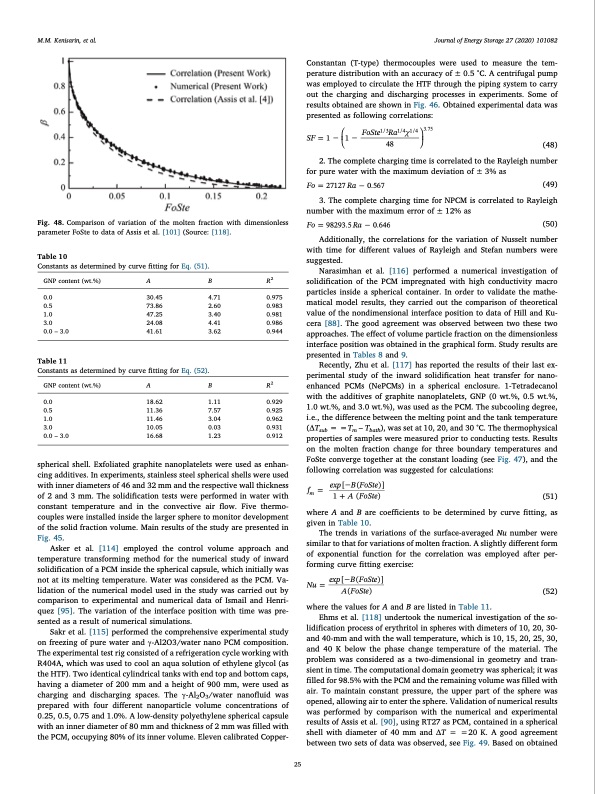

M.M. Kenisarin, et al. Journal of Energy Storage 27 (2020) 101082 Constantan (T-type) thermocouples were used to measure the tem- perature distribution with an accuracy of ± 0.5 °C. A centrifugal pump was employed to circulate the HTF through the piping system to carry out the charging and discharging processes in experiments. Some of results obtained are shown in Fig. 46. Obtained experimental data was presented as following correlations: FoSte1/3Ra1/4 1/4 3.75 48 (48) Fig. 48. Comparison of variation of the molten fraction with dimensionless parameter FoSte to data of Assis et al. [101] (Source: [118]. Table 10 Constants as determined by curve fitting for Eq. (51). SF = 1 1 2. The complete charging time is correlated to the Rayleigh number for pure water with the maximum deviation of ± 3% as Fo = 27127 Ra 0.567 3. The complete charging time for NPCM is correlated to Rayleigh number with the maximum error of ± 12% as Fo = 98293.5 Ra 0.646 (50) Additionally, the correlations for the variation of Nusselt number with time for different values of Rayleigh and Stefan numbers were suggested. Narasimhan et al. [116] performed a numerical investigation of solidification of the PCM impregnated with high conductivity macro particles inside a spherical container. In order to validate the mathe- matical model results, they carried out the comparison of theoretical value of the nondimensional interface position to data of Hill and Ku- cera [88]. The good agreement was observed between two these two approaches. The effect of volume particle fraction on the dimensionless interface position was obtained in the graphical form. Study results are presented in Tables 8 and 9. Recently, Zhu et al. [117] has reported the results of their last ex- perimental study of the inward solidification heat transfer for nano- enhanced PCMs (NePCMs) in a spherical enclosure. 1-Tetradecanol with the additives of graphite nanoplatelets, GNP (0 wt.%, 0.5 wt.%, 1.0 wt.%, and 3.0 wt.%), was used as the PCM. The subcooling degree, i.e., the difference between the melting point and the tank temperature (ΔTsub = =Tm – Tbath), was set at 10, 20, and 30 °C. The thermophysical properties of samples were measured prior to conducting tests. Results on the molten fraction change for three boundary temperatures and FoSte converge together at the constant loading (see Fig. 47), and the following correlation was suggested for calculations: f = exp[ B(FoSte)] m 1 + A (FoSte) (51) where A and B are coefficients to be determined by curve fitting, as given in Table 10. The trends in variations of the surface-averaged Nu number were similar to that for variations of molten fraction. A slightly different form of exponential function for the correlation was employed after per- forming curve fitting exercise: Nu = exp[ B(FoSte)] A (FoSte) (52) where the values for A and B are listed in Table 11. Ehms et al. [118] undertook the numerical investigation of the so- lidification process of erythritol in spheres with dimeters of 10, 20, 30- and 40-mm and with the wall temperature, which is 10, 15, 20, 25, 30, and 40 K below the phase change temperature of the material. The problem was considered as a two-dimensional in geometry and tran- sient in time. The computational domain geometry was spherical; it was filled for 98.5% with the PCM and the remaining volume was filled with air. To maintain constant pressure, the upper part of the sphere was opened, allowing air to enter the sphere. Validation of numerical results was performed by comparison with the numerical and experimental results of Assis et al. [90], using RT27 as PCM, contained in a spherical shell with diameter of 40 mm and ΔT = =20 K. A good agreement between two sets of data was observed, see Fig. 49. Based on obtained (49) GNP content (wt.%) 0.0 0.5 1.0 3.0 0.0 – 3.0 Table 11 A B 30.45 4.71 73.86 2.60 47.25 3.40 24.08 4.41 41.61 3.62 R2 0.975 0.983 0.981 0.986 0.944 R2 0.929 0.925 0.962 0.931 0.912 Constants as determined by curve fitting for Eq. (52). GNP content (wt.%) 0.0 0.5 1.0 3.0 0.0 – 3.0 A B 18.62 1.11 11.36 7.57 11.46 3.04 10.05 0.03 16.68 1.23 spherical shell. Exfoliated graphite nanoplatelets were used as enhan- cing additives. In experiments, stainless steel spherical shells were used with inner diameters of 46 and 32 mm and the respective wall thickness of 2 and 3 mm. The solidification tests were performed in water with constant temperature and in the convective air flow. Five thermo- couples were installed inside the larger sphere to monitor development of the solid fraction volume. Main results of the study are presented in Fig. 45. Asker et al. [114] employed the control volume approach and temperature transforming method for the numerical study of inward solidification of a PCM inside the spherical capsule, which initially was not at its melting temperature. Water was considered as the PCM. Va- lidation of the numerical model used in the study was carried out by comparison to experimental and numerical data of Ismail and Henri- quez [95]. The variation of the interface position with time was pre- sented as a result of numerical simulations. Sakr et al. [115] performed the comprehensive experimental study on freezing of pure water and γ-Al2O3/water nano PCM composition. The experimental test rig consisted of a refrigeration cycle working with R404A, which was used to cool an aqua solution of ethylene glycol (as the HTF). Two identical cylindrical tanks with end top and bottom caps, having a diameter of 200 mm and a height of 900 mm, were used as charging and discharging spaces. The γ-Al2O3/water nanofluid was prepared with four different nanoparticle volume concentrations of 0.25, 0.5, 0.75 and 1.0%. A low-density polyethylene spherical capsule with an inner diameter of 80 mm and thickness of 2 mm was filled with the PCM, occupying 80% of its inner volume. Eleven calibrated Copper- 25PDF Image | Journal of Energy Storage 27

PDF Search Title:

Journal of Energy Storage 27Original File Name Searched:

tes-spherical-ball-storage-paraffin.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Sand Battery Sand and Paraffin for TES Thermo Energy Storage More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |