PDF Publication Title:

Text from PDF Page: 006

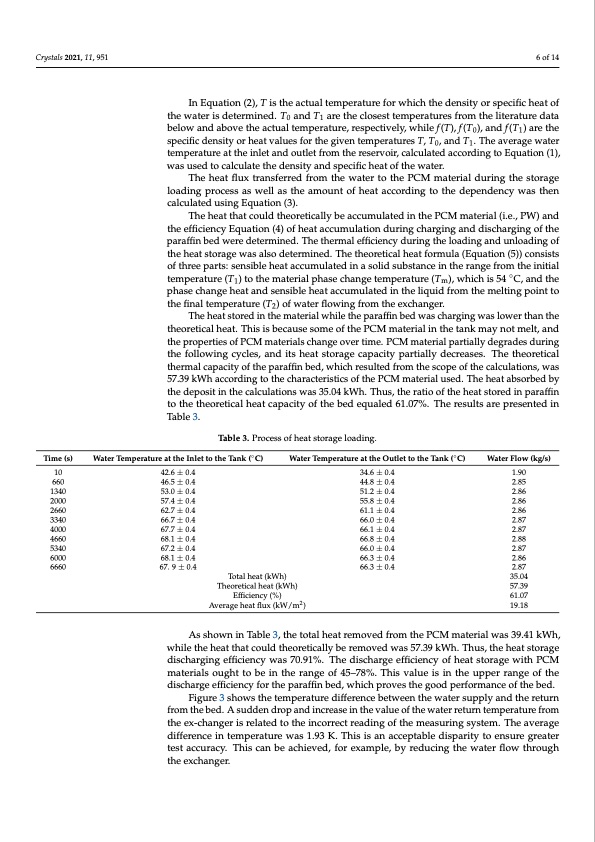

Crystals 2021, 11, 951 6 of 14 Time (s) 10 660 1340 2000 2660 3340 4000 4660 5340 6000 6660 Water Temperature at the Inlet to the Tank (◦C) 42.6 ± 0.4 Water Temperature at the Outlet to the Tank (◦C) 34.6 ± 0.4 44.8 ± 0.4 51.2 ± 0.4 55.8 ± 0.4 61.1 ± 0.4 66.0 ± 0.4 66.1 ± 0.4 66.8 ± 0.4 66.0 ± 0.4 66.3 ± 0.4 66.3 ± 0.4 Water Flow (kg/s) 1.90 2.85 2.86 2.86 2.86 2.87 2.87 2.88 2.87 2.86 2.87 35.04 57.39 61.07 19.18 In Equation (2), T is the actual temperature for which the density or specific heat of the water is determined. T0 and T1 are the closest temperatures from the literature data below and above the actual temperature, respectively, while f (T), f (T0), and f (T1) are the specific density or heat values for the given temperatures T, T0, and T1. The average water temperature at the inlet and outlet from the reservoir, calculated according to Equation (1), was used to calculate the density and specific heat of the water. The heat flux transferred from the water to the PCM material during the storage loading process as well as the amount of heat according to the dependency was then calculated using Equation (3). The heat that could theoretically be accumulated in the PCM material (i.e., PW) and the efficiency Equation (4) of heat accumulation during charging and discharging of the paraffin bed were determined. The thermal efficiency during the loading and unloading of the heat storage was also determined. The theoretical heat formula (Equation (5)) consists of three parts: sensible heat accumulated in a solid substance in the range from the initial temperature (T1) to the material phase change temperature (Tm), which is 54 ◦C, and the phase change heat and sensible heat accumulated in the liquid from the melting point to the final temperature (T2) of water flowing from the exchanger. The heat stored in the material while the paraffin bed was charging was lower than the theoretical heat. This is because some of the PCM material in the tank may not melt, and the properties of PCM materials change over time. PCM material partially degrades during the following cycles, and its heat storage capacity partially decreases. The theoretical thermal capacity of the paraffin bed, which resulted from the scope of the calculations, was 57.39 kWh according to the characteristics of the PCM material used. The heat absorbed by the deposit in the calculations was 35.04 kWh. Thus, the ratio of the heat stored in paraffin to the theoretical heat capacity of the bed equaled 61.07%. The results are presented in Table 3. Table 3. Process of heat storage loading. 46.5 ± 0.4 53.0 ± 0.4 57.4 ± 0.4 62.7 ± 0.4 66.7 ± 0.4 67.7 ± 0.4 68.1 ± 0.4 67.2 ± 0.4 68.1 ± 0.4 67. 9 ± 0.4 Total heat (kWh) Theoretical heat (kWh) Efficiency (%) Average heat flux (kW/m2) As shown in Table 3, the total heat removed from the PCM material was 39.41 kWh, while the heat that could theoretically be removed was 57.39 kWh. Thus, the heat storage discharging efficiency was 70.91%. The discharge efficiency of heat storage with PCM materials ought to be in the range of 45–78%. This value is in the upper range of the discharge efficiency for the paraffin bed, which proves the good performance of the bed. Figure 3 shows the temperature difference between the water supply and the return from the bed. A sudden drop and increase in the value of the water return temperature from the ex-changer is related to the incorrect reading of the measuring system. The average difference in temperature was 1.93 K. This is an acceptable disparity to ensure greater test accuracy. This can be achieved, for example, by reducing the water flow through the exchanger.PDF Image | Paraffin Wax As a Phase Changing Material PCM

PDF Search Title:

Paraffin Wax As a Phase Changing Material PCMOriginal File Name Searched:

crystals-11-00951.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Sand Battery Sand and Paraffin for TES Thermo Energy Storage More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |