PDF Publication Title:

Text from PDF Page: 008

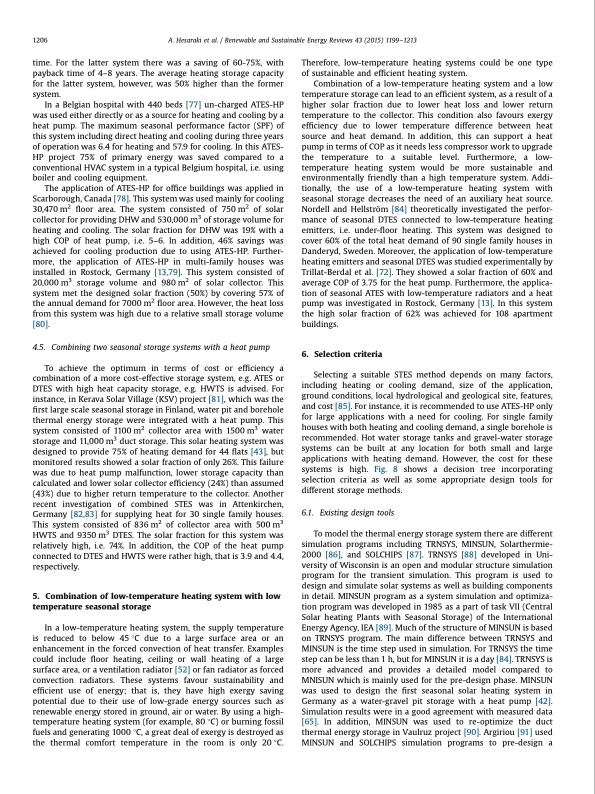

1206 A. Hesaraki et al. / Renewable and Sustainable Energy Reviews 43 (2015) 1199–1213 time. For the latter system there was a saving of 60-75%, with payback time of 4–8 years. The average heating storage capacity for the latter system, however, was 50% higher than the former system. In a Belgian hospital with 440 beds [77] un-charged ATES-HP was used either directly or as a source for heating and cooling by a heat pump. The maximum seasonal performance factor (SPF) of this system including direct heating and cooling during three years of operation was 6.4 for heating and 57.9 for cooling. In this ATES- HP project 75% of primary energy was saved compared to a conventional HVAC system in a typical Belgium hospital, i.e. using boiler and cooling equipment. The application of ATES-HP for office buildings was applied in Scarborough, Canada [78]. This system was used mainly for cooling 30,470 m2 floor area. The system consisted of 750 m2 of solar collector for providing DHW and 530,000 m3 of storage volume for heating and cooling. The solar fraction for DHW was 19% with a high COP of heat pump, i.e. 5–6. In addition, 46% savings was achieved for cooling production due to using ATES-HP. Further- more, the application of ATES-HP in multi-family houses was installed in Rostock, Germany [13,79]. This system consisted of 20,000 m3 storage volume and 980 m2 of solar collector. This system met the designed solar fraction (50%) by covering 57% of the annual demand for 7000 m2 floor area. However, the heat loss from this system was high due to a relative small storage volume [80]. 4.5. Combining two seasonal storage systems with a heat pump To achieve the optimum in terms of cost or efficiency a combination of a more cost-effective storage system, e.g. ATES or DTES with high heat capacity storage, e.g. HWTS is advised. For instance, in Kerava Solar Village (KSV) project [81], which was the first large scale seasonal storage in Finland, water pit and borehole thermal energy storage were integrated with a heat pump. This system consisted of 1100 m2 collector area with 1500 m3 water storage and 11,000 m3 duct storage. This solar heating system was designed to provide 75% of heating demand for 44 flats [43], but monitored results showed a solar fraction of only 26%. This failure was due to heat pump malfunction, lower storage capacity than calculated and lower solar collector efficiency (24%) than assumed (43%) due to higher return temperature to the collector. Another recent investigation of combined STES was in Attenkirchen, Germany [82,83] for supplying heat for 30 single family houses. This system consisted of 836 m2 of collector area with 500 m3 HWTS and 9350 m3 DTES. The solar fraction for this system was relatively high, i.e. 74%. In addition, the COP of the heat pump connected to DTES and HWTS were rather high, that is 3.9 and 4.4, respectively. 5. Combination of low-temperature heating system with low temperature seasonal storage In a low-temperature heating system, the supply temperature is reduced to below 451C due to a large surface area or an enhancement in the forced convection of heat transfer. Examples could include floor heating, ceiling or wall heating of a large surface area, or a ventilation radiator [52] or fan radiator as forced convection radiators. These systems favour sustainability and efficient use of energy; that is, they have high exergy saving potential due to their use of low-grade energy sources such as renewable energy stored in ground, air or water. By using a high- temperature heating system (for example, 80 1C) or burning fossil fuels and generating 1000 1C, a great deal of exergy is destroyed as the thermal comfort temperature in the room is only 201C. Therefore, low-temperature heating systems could be one type of sustainable and efficient heating system. Combination of a low-temperature heating system and a low temperature storage can lead to an efficient system, as a result of a higher solar fraction due to lower heat loss and lower return temperature to the collector. This condition also favours exergy efficiency due to lower temperature difference between heat source and heat demand. In addition, this can support a heat pump in terms of COP as it needs less compressor work to upgrade the temperature to a suitable level. Furthermore, a low- temperature heating system would be more sustainable and environmentally friendly than a high temperature system. Addi- tionally, the use of a low-temperature heating system with seasonal storage decreases the need of an auxiliary heat source. Nordell and Hellström [84] theoretically investigated the perfor- mance of seasonal DTES connected to low-temperature heating emitters, i.e. under-floor heating. This system was designed to cover 60% of the total heat demand of 90 single family houses in Danderyd, Sweden. Moreover, the application of low-temperature heating emitters and seasonal DTES was studied experimentally by Trillat-Berdal et al. [72]. They showed a solar fraction of 60% and average COP of 3.75 for the heat pump. Furthermore, the applica- tion of seasonal ATES with low-temperature radiators and a heat pump was investigated in Rostock, Germany [13]. In this system the high solar fraction of 62% was achieved for 108 apartment buildings. 6. Selection criteria Selecting a suitable STES method depends on many factors, including heating or cooling demand, size of the application, ground conditions, local hydrological and geological site, features, and cost [85]. For instance, it is recommended to use ATES-HP only for large applications with a need for cooling. For single family houses with both heating and cooling demand, a single borehole is recommended. Hot water storage tanks and gravel-water storage systems can be built at any location for both small and large applications with heating demand. However, the cost for these systems is high. Fig. 8 shows a decision tree incorporating selection criteria as well as some appropriate design tools for different storage methods. 6.1. Existing design tools To model the thermal energy storage system there are different simulation programs including TRNSYS, MINSUN, Solarthermie- 2000 [86], and SOLCHIPS [87]. TRNSYS [88] developed in Uni- versity of Wisconsin is an open and modular structure simulation program for the transient simulation. This program is used to design and simulate solar systems as well as building components in detail. MINSUN program as a system simulation and optimiza- tion program was developed in 1985 as a part of task VII (Central Solar heating Plants with Seasonal Storage) of the International Energy Agency, IEA [89]. Much of the structure of MINSUN is based on TRNSYS program. The main difference between TRNSYS and MINSUN is the time step used in simulation. For TRNSYS the time step can be less than 1 h, but for MINSUN it is a day [84]. TRNSYS is more advanced and provides a detailed model compared to MNISUN which is mainly used for the pre-design phase. MINSUN was used to design the first seasonal solar heating system in Germany as a water-gravel pit storage with a heat pump [42]. Simulation results were in a good agreement with measured data [65]. In addition, MINSUN was used to re-optimize the duct thermal energy storage in Vaulruz project [90]. Argiriou [91] used MINSUN and SOLCHIPS simulation programs to pre-design aPDF Image | Renewable and Sustainable Energy Reviews 43

PDF Search Title:

Renewable and Sustainable Energy Reviews 43Original File Name Searched:

tes-heat-pumps.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Sand Battery Sand and Paraffin for TES Thermo Energy Storage More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |