PDF Publication Title:

Text from PDF Page: 008

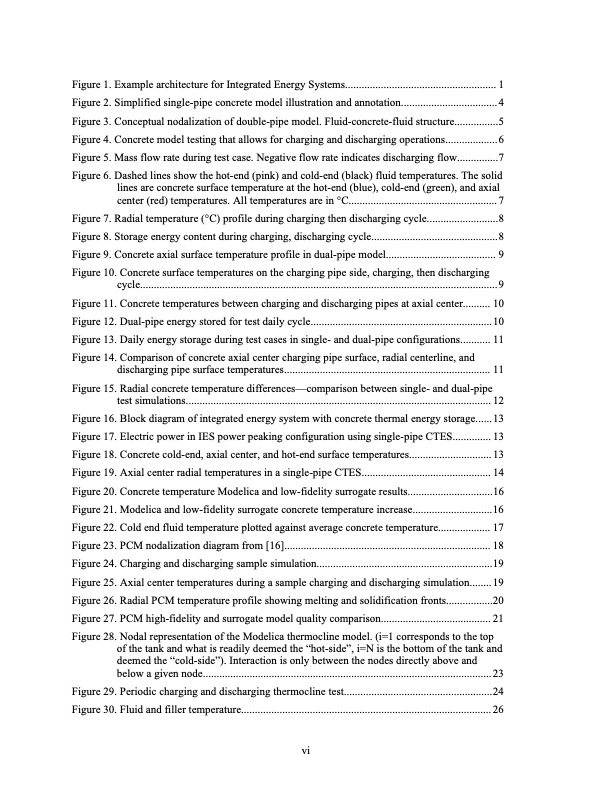

Figure 1. Example architecture for Integrated Energy Systems....................................................... 1 Figure 2. Simplified single-pipe concrete model illustration and annotation................................... 4 Figure 3. Conceptual nodalization of double-pipe model. Fluid-concrete-fluid structure................5 Figure 4. Concrete model testing that allows for charging and discharging operations...................6 Figure 5. Mass flow rate during test case. Negative flow rate indicates discharging flow...............7 Figure 6. Dashed lines show the hot-end (pink) and cold-end (black) fluid temperatures. The solid lines are concrete surface temperature at the hot-end (blue), cold-end (green), and axial center (red) temperatures. All temperatures are in °C...................................................... 7 Figure 7. Radial temperature (°C) profile during charging then discharging cycle..........................8 Figure 8. Storage energy content during charging, discharging cycle..............................................8 Figure 9. Concrete axial surface temperature profile in dual-pipe model........................................ 9 Figure 10. Concrete surface temperatures on the charging pipe side, charging, then discharging cycle.................................................................................................................................. 9 Figure 11. Concrete temperatures between charging and discharging pipes at axial center.......... 10 Figure 12. Dual-pipe energy stored for test daily cycle..................................................................10 Figure 13. Daily energy storage during test cases in single- and dual-pipe configurations........... 11 Figure 14. Comparison of concrete axial center charging pipe surface, radial centerline, and discharging pipe surface temperatures........................................................................... 11 Figure 15. Radial concrete temperature differences—comparison between single- and dual-pipe test simulations............................................................................................................... 12 Figure 16. Block diagram of integrated energy system with concrete thermal energy storage......13 Figure 17. Electric power in IES power peaking configuration using single-pipe CTES.............. 13 Figure 18. Concrete cold-end, axial center, and hot-end surface temperatures.............................. 13 Figure 19. Axial center radial temperatures in a single-pipe CTES............................................... 14 Figure 20. Concrete temperature Modelica and low-fidelity surrogate results...............................16 Figure 21. Modelica and low-fidelity surrogate concrete temperature increase.............................16 Figure 22. Cold end fluid temperature plotted against average concrete temperature................... 17 Figure 23. PCM nodalization diagram from [16]........................................................................... 18 Figure 24. Charging and discharging sample simulation................................................................19 Figure 25. Axial center temperatures during a sample charging and discharging simulation........ 19 Figure 26. Radial PCM temperature profile showing melting and solidification fronts.................20 Figure 27. PCM high-fidelity and surrogate model quality comparison........................................ 21 Figure 28. Nodal representation of the Modelica thermocline model. (i=1 corresponds to the top of the tank and what is readily deemed the “hot-side”, i=N is the bottom of the tank and deemed the “cold-side”). Interaction is only between the nodes directly above and below a given node......................................................................................................... 23 Figure 29. Periodic charging and discharging thermocline test......................................................24 Figure 30. Fluid and filler temperature........................................................................................... 26 viPDF Image | Thermal Energy Storage Model Development

PDF Search Title:

Thermal Energy Storage Model DevelopmentOriginal File Name Searched:

Sort_44972.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Sand Battery Sand and Paraffin for TES Thermo Energy Storage More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |