PDF Publication Title:

Text from PDF Page: 035

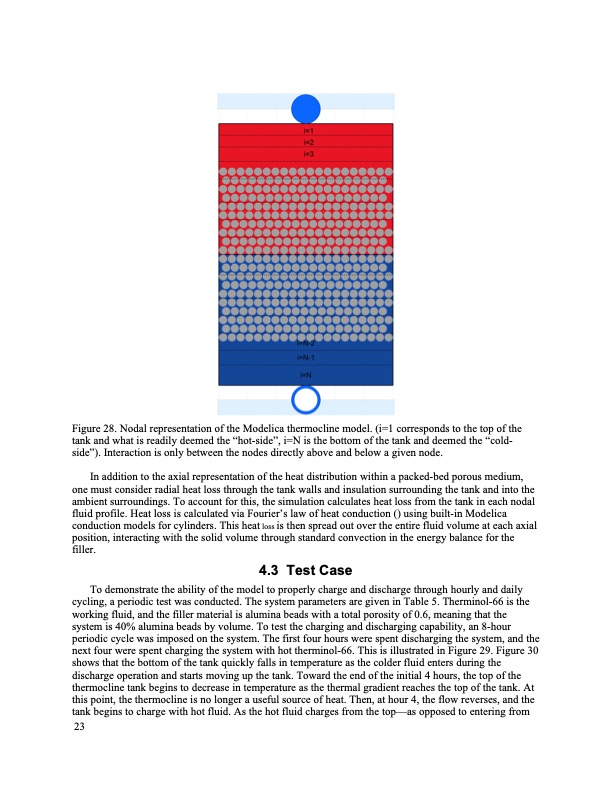

Figure 28. Nodal representation of the Modelica thermocline model. (i=1 corresponds to the top of the tank and what is readily deemed the “hot-side”, i=N is the bottom of the tank and deemed the “cold- side”). Interaction is only between the nodes directly above and below a given node. In addition to the axial representation of the heat distribution within a packed-bed porous medium, one must consider radial heat loss through the tank walls and insulation surrounding the tank and into the ambient surroundings. To account for this, the simulation calculates heat loss from the tank in each nodal fluid profile. Heat loss is calculated via Fourier’s law of heat conduction () using built-in Modelica conduction models for cylinders. This heat loss is then spread out over the entire fluid volume at each axial position, interacting with the solid volume through standard convection in the energy balance for the filler. 4.3 Test Case To demonstrate the ability of the model to properly charge and discharge through hourly and daily cycling, a periodic test was conducted. The system parameters are given in Table 5. Therminol-66 is the working fluid, and the filler material is alumina beads with a total porosity of 0.6, meaning that the system is 40% alumina beads by volume. To test the charging and discharging capability, an 8-hour periodic cycle was imposed on the system. The first four hours were spent discharging the system, and the next four were spent charging the system with hot therminol-66. This is illustrated in Figure 29. Figure 30 shows that the bottom of the tank quickly falls in temperature as the colder fluid enters during the discharge operation and starts moving up the tank. Toward the end of the initial 4 hours, the top of the thermocline tank begins to decrease in temperature as the thermal gradient reaches the top of the tank. At this point, the thermocline is no longer a useful source of heat. Then, at hour 4, the flow reverses, and the tank begins to charge with hot fluid. As the hot fluid charges from the top—as opposed to entering from 23PDF Image | Thermal Energy Storage Model Development

PDF Search Title:

Thermal Energy Storage Model DevelopmentOriginal File Name Searched:

Sort_44972.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Sand Battery Sand and Paraffin for TES Thermo Energy Storage More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |