PDF Publication Title:

Text from PDF Page: 011

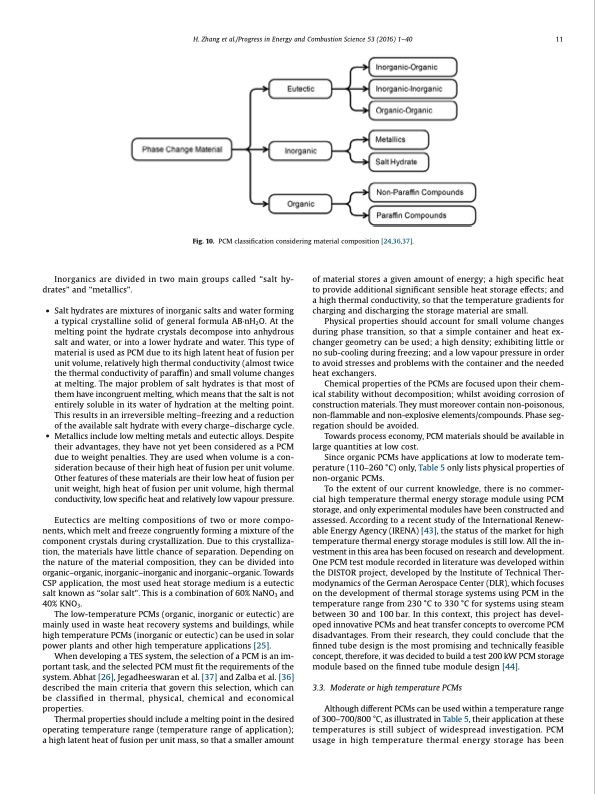

Inorganics are divided in two main groups called “salt hy- drates” and “metallics”. • Salt hydrates are mixtures of inorganic salts and water forming a typical crystalline solid of general formula AB·nH2O. At the melting point the hydrate crystals decompose into anhydrous salt and water, or into a lower hydrate and water. This type of material is used as PCM due to its high latent heat of fusion per unit volume, relatively high thermal conductivity (almost twice the thermal conductivity of paraffin) and small volume changes at melting. The major problem of salt hydrates is that most of them have incongruent melting, which means that the salt is not entirely soluble in its water of hydration at the melting point. This results in an irreversible melting–freezing and a reduction of the available salt hydrate with every charge–discharge cycle. • Metallics include low melting metals and eutectic alloys. Despite their advantages, they have not yet been considered as a PCM due to weight penalties. They are used when volume is a con- sideration because of their high heat of fusion per unit volume. Other features of these materials are their low heat of fusion per unit weight, high heat of fusion per unit volume, high thermal conductivity, low specific heat and relatively low vapour pressure. Eutectics are melting compositions of two or more compo- nents, which melt and freeze congruently forming a mixture of the component crystals during crystallization. Due to this crystalliza- tion, the materials have little chance of separation. Depending on the nature of the material composition, they can be divided into organic–organic, inorganic–inorganic and inorganic–organic. Towards CSP application, the most used heat storage medium is a eutectic salt known as “solar salt”. This is a combination of 60% NaNO3 and 40% KNO3. The low-temperature PCMs (organic, inorganic or eutectic) are mainly used in waste heat recovery systems and buildings, while high temperature PCMs (inorganic or eutectic) can be used in solar power plants and other high temperature applications [25]. When developing a TES system, the selection of a PCM is an im- portant task, and the selected PCM must fit the requirements of the system. Abhat [26], Jegadheeswaran et al. [37] and Zalba et al. [36] described the main criteria that govern this selection, which can be classified in thermal, physical, chemical and economical properties. Thermal properties should include a melting point in the desired operating temperature range (temperature range of application); a high latent heat of fusion per unit mass, so that a smaller amount of material stores a given amount of energy; a high specific heat to provide additional significant sensible heat storage effects; and a high thermal conductivity, so that the temperature gradients for charging and discharging the storage material are small. Physical properties should account for small volume changes during phase transition, so that a simple container and heat ex- changer geometry can be used; a high density; exhibiting little or no sub-cooling during freezing; and a low vapour pressure in order to avoid stresses and problems with the container and the needed heat exchangers. Chemical properties of the PCMs are focused upon their chem- ical stability without decomposition; whilst avoiding corrosion of construction materials. They must moreover contain non-poisonous, non-flammable and non-explosive elements/compounds. Phase seg- regation should be avoided. Towards process economy, PCM materials should be available in large quantities at low cost. Since organic PCMs have applications at low to moderate tem- perature (110–260 °C) only, Table 5 only lists physical properties of non-organic PCMs. To the extent of our current knowledge, there is no commer- cial high temperature thermal energy storage module using PCM storage, and only experimental modules have been constructed and assessed. According to a recent study of the International Renew- able Energy Agency (IRENA) [43], the status of the market for high temperature thermal energy storage modules is still low. All the in- vestment in this area has been focused on research and development. One PCM test module recorded in literature was developed within the DISTOR project, developed by the Institute of Technical Ther- modynamics of the German Aerospace Center (DLR), which focuses on the development of thermal storage systems using PCM in the temperature range from 230 °C to 330 °C for systems using steam between 30 and 100 bar. In this context, this project has devel- oped innovative PCMs and heat transfer concepts to overcome PCM disadvantages. From their research, they could conclude that the finned tube design is the most promising and technically feasible concept, therefore, it was decided to build a test 200 kW PCM storage module based on the finned tube module design [44]. 3.3. Moderate or high temperature PCMs Although different PCMs can be used within a temperature range of 300–700/800 °C, as illustrated in Table 5, their application at these temperatures is still subject of widespread investigation. PCM usage in high temperature thermal energy storage has been H. Zhang et al./Progress in Energy and Combustion Science 53 (2016) 1–40 11 Fig. 10. PCM classification considering material composition [24,36,37].PDF Image | Thermal energy storage: Recent developments

PDF Search Title:

Thermal energy storage: Recent developmentsOriginal File Name Searched:

3-Thermal-Energy-storage-recent-developments-and-practical-aspects.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Sand Battery Sand and Paraffin for TES Thermo Energy Storage More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |