PDF Publication Title:

Text from PDF Page: 066

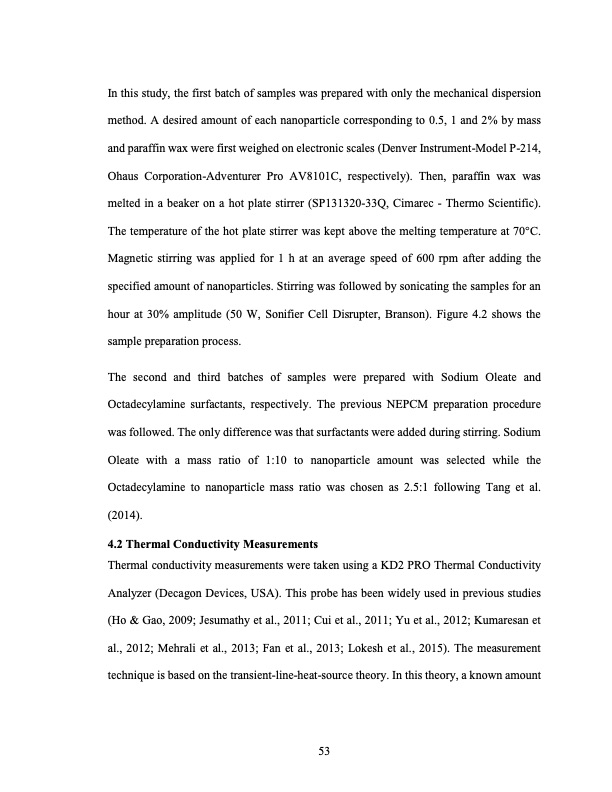

In this study, the first batch of samples was prepared with only the mechanical dispersion method. A desired amount of each nanoparticle corresponding to 0.5, 1 and 2% by mass and paraffin wax were first weighed on electronic scales (Denver Instrument-Model P-214, Ohaus Corporation-Adventurer Pro AV8101C, respectively). Then, paraffin wax was melted in a beaker on a hot plate stirrer (SP131320-33Q, Cimarec - Thermo Scientific). The temperature of the hot plate stirrer was kept above the melting temperature at 70°C. Magnetic stirring was applied for 1 h at an average speed of 600 rpm after adding the specified amount of nanoparticles. Stirring was followed by sonicating the samples for an hour at 30% amplitude (50 W, Sonifier Cell Disrupter, Branson). Figure 4.2 shows the sample preparation process. The second and third batches of samples were prepared with Sodium Oleate and Octadecylamine surfactants, respectively. The previous NEPCM preparation procedure was followed. The only difference was that surfactants were added during stirring. Sodium Oleate with a mass ratio of 1:10 to nanoparticle amount was selected while the Octadecylamine to nanoparticle mass ratio was chosen as 2.5:1 following Tang et al. (2014). 4.2 Thermal Conductivity Measurements Thermal conductivity measurements were taken using a KD2 PRO Thermal Conductivity Analyzer (Decagon Devices, USA). This probe has been widely used in previous studies (Ho & Gao, 2009; Jesumathy et al., 2011; Cui et al., 2011; Yu et al., 2012; Kumaresan et al., 2012; Mehrali et al., 2013; Fan et al., 2013; Lokesh et al., 2015). The measurement technique is based on the transient-line-heat-source theory. In this theory, a known amount 53PDF Image | THERMAL ENERGY STORAGE USING PARAFFIN WAX

PDF Search Title:

THERMAL ENERGY STORAGE USING PARAFFIN WAXOriginal File Name Searched:

PARAFFIN-WAX-TES.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Sand Battery Sand and Paraffin for TES Thermo Energy Storage More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |