PDF Publication Title:

Text from PDF Page: 004

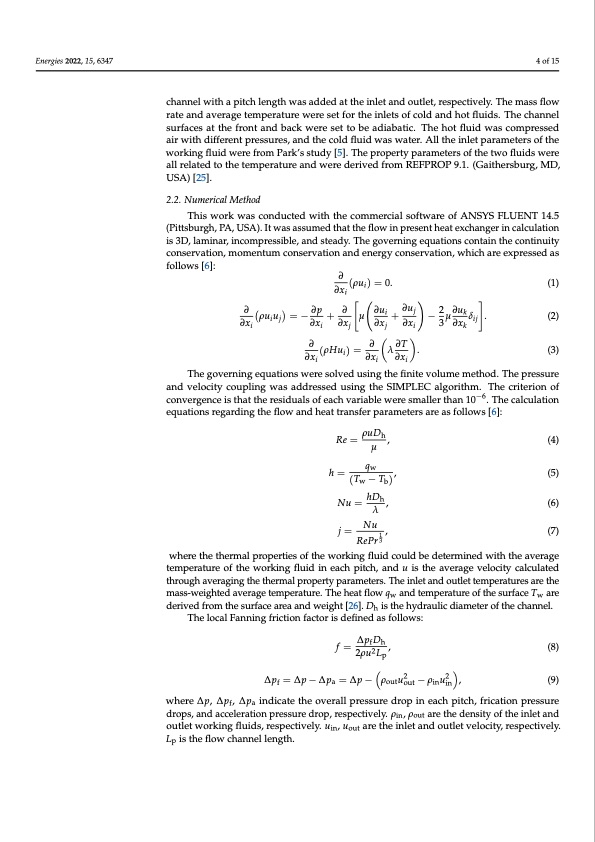

Energies 2022, 15, 6347 4 of 15 channel with a pitch length was added at the inlet and outlet, respectively. The mass flow rate and average temperature were set for the inlets of cold and hot fluids. The channel surfaces at the front and back were set to be adiabatic. The hot fluid was compressed air with different pressures, and the cold fluid was water. All the inlet parameters of the working fluid were from Park’s study [5]. The property parameters of the two fluids were all related to the temperature and were derived from REFPROP 9.1. (Gaithersburg, MD, USA) [25]. 2.2. Numerical Method This work was conducted with the commercial software of ANSYS FLUENT 14.5 (Pittsburgh, PA, USA). It was assumed that the flow in present heat exchanger in calculation is 3D, laminar, incompressible, and steady. The governing equations contain the continuity conservation, momentum conservation and energy conservation, which are expressed as follows [6]: ∂ (ρui) = 0. (1) ∂xi ∂ρuiuj=−∂p+∂ μ∂ui+∂uj −2μ∂ukδij. (2) 3 ∂xk (3) ∂xi ∂xi ∂xj ∂ ∂xi ∂xj ∂xi ∂ ∂T (ρHui) = ∂xi λ . ∂xi The governing equations were solved using the finite volume method. The pressure and velocity coupling was addressed using the SIMPLEC algorithm. The criterion of convergence is that the residuals of each variable were smaller than 10−6. The calculation equations regarding the flow and heat transfer parameters are as follows [6]: Re = ρuDh , (4) μ h= qw , (5) (Tw − Tb) Nu = hDh , (6) λ j= Nu , (7) R e P r 13 where the thermal properties of the working fluid could be determined with the average temperature of the working fluid in each pitch, and u is the average velocity calculated through averaging the thermal property parameters. The inlet and outlet temperatures are the mass-weighted average temperature. The heat flow qw and temperature of the surface Tw are derived from the surface area and weight [26]. Dh is the hydraulic diameter of the channel. The local Fanning friction factor is defined as follows: f = ∆pfDh , (8) 2ρu2 Lp 22 ∆pf = ∆p−∆pa = ∆p− ρoutuout −ρinuin , (9) where ∆p, ∆pf, ∆pa indicate the overall pressure drop in each pitch, frication pressure drops, and acceleration pressure drop, respectively. ρin, ρout are the density of the inlet and outlet working fluids, respectively. uin, uout are the inlet and outlet velocity, respectively. Lp is the flow channel length.PDF Image | Thermal–Hydraulic Performance of a Printed Circuit Heat Exchanger

PDF Search Title:

Thermal–Hydraulic Performance of a Printed Circuit Heat ExchangerOriginal File Name Searched:

energies-15-06347.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Sand Battery Sand and Paraffin for TES Thermo Energy Storage More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |