PDF Publication Title:

Text from PDF Page: 009

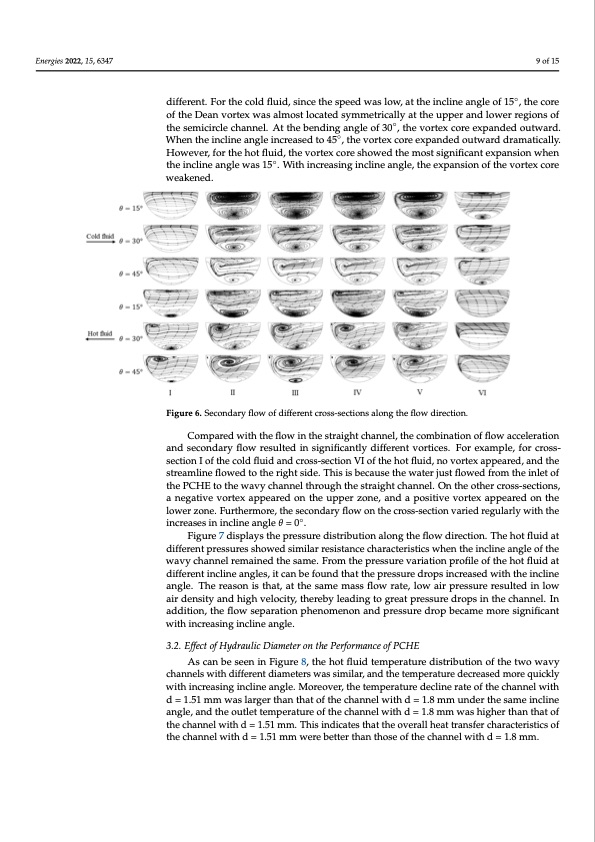

Energies 2022, 15, x FOR PEER REVIEW 9 of 15 Energies 2022, 15, 6347 9 of 15 For the cold fluid, since the speed was low, at the incline angle of 15°, the core of the Dean different. For the cold fluid, since the speed was low, at the incline angle of 15◦, the core vortex was almost located symmetrically at the upper and lower regions of the semicircle of the Dean vortex was almost located symmetrically at the upper and lower regions of channel. At the bending angle of 30°, the vortex core expanded outward. When the incline the semicircle channel. At the bending angle of 30◦, the vortex core expanded outward. angle increased to 45°, the vortex core◦ expanded outward dramatically. However, for the When the incline angle increased to 45 , the vortex core expanded outward dramatically. hot fluid, the vortex core showed the most significant expansion when the incline angle was However, for the hot fluid, the vortex core showed the most significant expansion when ◦ 15t°h.eWinitchlininecarnegalseinwgaisn1c5lin.eWainthglien,crtheaeseinxgpaincslionneaonfgtlhee,tvhoeretxepxacnosrieonwoefatkhenveodr.texcore weakened. Figure 6. Secondary flow of different cross-sections along the flow direction. Figure 6. Secondary flow of different cross-sections along the flow direction. Compared with the flow in the straight channel, the combination of flow acceleration Compared with the flow in the straight channel, the combination of flow acceleration and secondary flow resulted in significantly different vortices. For example, for cross- and secondary flow resulted in significantly different vortices. For example, for cross-sec- section I of the cold fluid and cross-section VI of the hot fluid, no vortex appeared, and the tion I of the cold fluid and cross-section VI of the hot fluid, no vortex appeared, and the streamline flowed to the right side. This is because the water just flowed from the inlet of strtehaemPClinHeEftlowthedwtaovtyhcehraingnhetlstihdreo.uTghitshiessbtreaciaguhtsechtahnenwela. tOenr jtuhsetoftlhoewrecdrofsrso-smectihoensin, let of thea PneCgHatEivteovtohretewx avpypecahraednnoenl therouupgpherthzeonsetr, aingdhtacphoasnitniveel. vOonrtethxeapoptheearecdrosns-tsheections, lower zone. Furthermore, the secondary flow on the cross-section varied regularly with the a negative vortex appeared on the upper zone, and a positive vortex appeared on the increases in incline angle θ = 0◦. lower zone. Furthermore, the secondary flow on the cross-section varied regularly with Figure 7 displays the pressure distribution along the flow direction. The hot fluid at the increases in incline angle 𝜃 = 0°. different pressures showed similar resistance characteristics when the incline angle of the Figure 7 displays the pressure distribution along the flow direction. The hot fluid at wavy channel remained the same. From the pressure variation profile of the hot fluid at different pressures showed similar resistance characteristics when the incline angle of the different incline angles, it can be found that the pressure drops increased with the incline wavy channel remained the same. From the pressure variation profile of the hot fluid at angle. The reason is that, at the same mass flow rate, low air pressure resulted in low different incline angles, it can be found that the pressure drops increased with the incline air density and high velocity, thereby leading to great pressure drops in the channel. In anagdled.itTiohne,rtheeasfloonwisetpharta,taiotnthpehseanmomeemnoanssafnlodwprreastseu,rleodwroapirbpecraemsseurmeoressuilgtneidficinanltowair with increasing incline angle. density and high velocity, thereby leading to great pressure drops in the channel. In ad- dition, the flow separation phenomenon and pressure drop became more significant with 3.2. Effect of Hydraulic Diameter on the Performance of PCHE increasing incline angle. As can be seen in Figure 8, the hot fluid temperature distribution of the two wavy channels with different diameters was similar, and the temperature decreased more quickly with increasing incline angle. Moreover, the temperature decline rate of the channel with d = 1.51 mm was larger than that of the channel with d = 1.8 mm under the same incline angle, and the outlet temperature of the channel with d = 1.8 mm was higher than that of the channel with d = 1.51 mm. This indicates that the overall heat transfer characteristics of the channel with d = 1.51 mm were better than those of the channel with d = 1.8 mm.PDF Image | Thermal–Hydraulic Performance of a Printed Circuit Heat Exchanger

PDF Search Title:

Thermal–Hydraulic Performance of a Printed Circuit Heat ExchangerOriginal File Name Searched:

energies-15-06347.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Sand Battery Sand and Paraffin for TES Thermo Energy Storage More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |