PDF Publication Title:

Text from PDF Page: 013

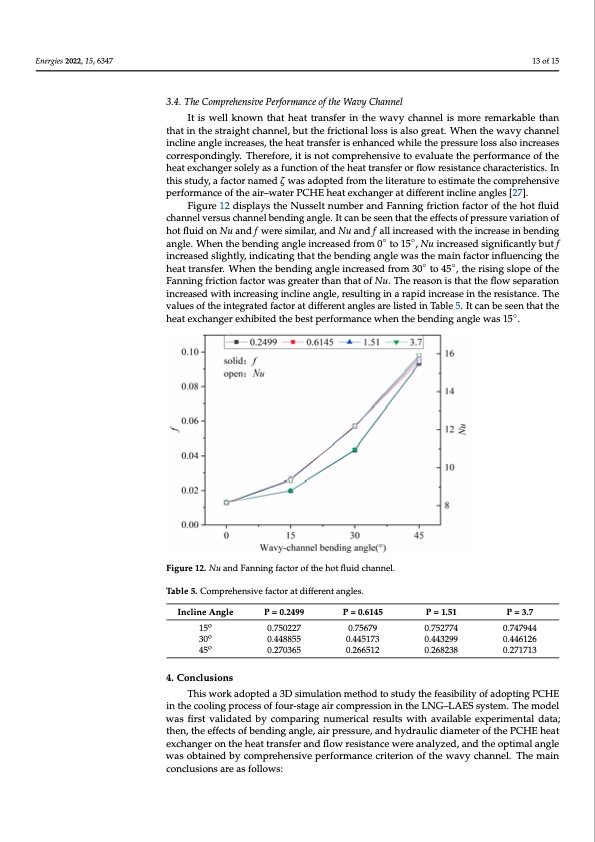

e e y e s e d n y g f n Energies 2022, 15, 6347 ferent trend. As seen in the figure, the heat flux of Ei was greater than that of Di, and th difference between the maxima and minima of the heat flux was smaller when the angl was smaller. This also confirms the conclusion that the flow direction changes in the wav channel can enhance the heat transfer. 13 of 15 3.4. The Comprehensive Performance of the Wavy Channel It is well known that heat transfer in the wavy channel is more remarkable than tha 3.4. The Comprehensive Performance of the Wavy Channel in the straight channel, but the frictional loss is also great. When the wavy channel inclin anglIet iinscwreallseksn,otwhenhtehat threaantstfrearnisfernihnatnhcedwwavhyilcehtahneneplreisssmuorreeloresms alrskoabinlecrtheasnes corre that in the straight channel, but the frictional loss is also great. When the wavy channel spondingly. Therefore, it is not comprehensive to evaluate the performance of the hea incline angle increases, the heat transfer is enhanced while the pressure loss also increases exchanger solely as a function of the heat transfer or flow resistance characteristics. In thi correspondingly. Therefore, it is not comprehensive to evaluate the performance of the study, a factor named 𝜁 was adopted from the literature to estimate the comprehensiv heat exchanger solely as a function of the heat transfer or flow resistance characteristics. In performance of the air–water PCHE heat exchanger at different incline angles [27]. this study, a factor named ζ was adopted from the literature to estimate the comprehensive Figure 12 displays the Nusselt number and Fanning friction factor of the hot flui performance of the air–water PCHE heat exchanger at different incline angles [27]. channel versus channel bending angle. It can be seen that the effects of pressure variatio Figure 12 displays the Nusselt number and Fanning friction factor of the hot fluid of hot fluid on Nu and f were similar, and Nu and f all increased with the increase in bend channel versus channel bending angle. It can be seen that the effects of pressure variation of hinogtflaunidgloen.WNuhaendtfhweebrensdiminilgar,aanngdleNiunacnredafseadllifnrcormeas0e°dtwoit1h5t°h,eNinucrienacsreeiansebdensdiignngificantl abnugtlfe.inWcrheanstehdesbleignhdtilnyg, aindgliecainticnrgeatsheadtftrhoemb0entdoi1n5g ,aNnugliencwreaasstehdesmignaifincfaancttloyrbiuntffluencin increased slightly, indicating that the bending angle was the main factor influencing the the heat transfer. When the bending angle increased from 30° to 45°, the rising slope o heat transfer. When the bending angle increased from 30◦ to 45◦, the rising slope of the the Fanning friction factor was greater than that of Nu. The reason is that the flow separa Fanning friction factor was greater than that of Nu. The reason is that the flow separation tion increased with increasing incline angle, resulting in a rapid increase in the resistance increased with increasing incline angle, resulting in a rapid increase in the resistance. The The values of the integrated factor at different angles are listed in Table 5. It can be see values of the integrated factor at different angles are listed in Table 5. It can be seen that the that the heat exchanger exhibited the best performance when the bendin◦ g angle was 15°. heat exchanger exhibited the best performance when the bending angle was 15 . ◦◦ Figurree1122. .NNuuanadndFaFnanninginfagcftoarctofrthoef hthoet flhuoitdfcluhiadnncehla. nnel. Table 5. Comprehensive factor at different angles. Table 5. Comprehensive factor at different angles. Incline Angle P = 0.2499 P = 0.6145 P = 1.51 P = 3.7 P = 3.7 Incline Angle P = 0.2499 P = 0.6145 P = 1.51 15o o 0.750227 15 0.750227 0.75679 0.752774 30o 0.747944 30o o 45 0.270365 0.266512 0.268238 0.446126 0.75679 0.448855 0.445173 0.443299 0.448855 0.445173 0.443299 0.446126 45o 0.270365 0.266512 0.268238 4. Conclusions 0.271713 0.752774 0.747944 0.271713 This work adopted a 3D simulation method to study the feasibility of adopting PCHE in the cooling process of four-stage air compression in the LNG–LAES system. The model was first validated by comparing numerical results with available experimental data; then, the effects of bending angle, air pressure, and hydraulic diameter of the PCHE heat exchanger on the heat transfer and flow resistance were analyzed, and the optimal angle was obtained by comprehensive performance criterion of the wavy channel. The main conclusions are as follows:PDF Image | Thermal–Hydraulic Performance of a Printed Circuit Heat Exchanger

PDF Search Title:

Thermal–Hydraulic Performance of a Printed Circuit Heat ExchangerOriginal File Name Searched:

energies-15-06347.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Sand Battery Sand and Paraffin for TES Thermo Energy Storage More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |