PDF Publication Title:

Text from PDF Page: 038

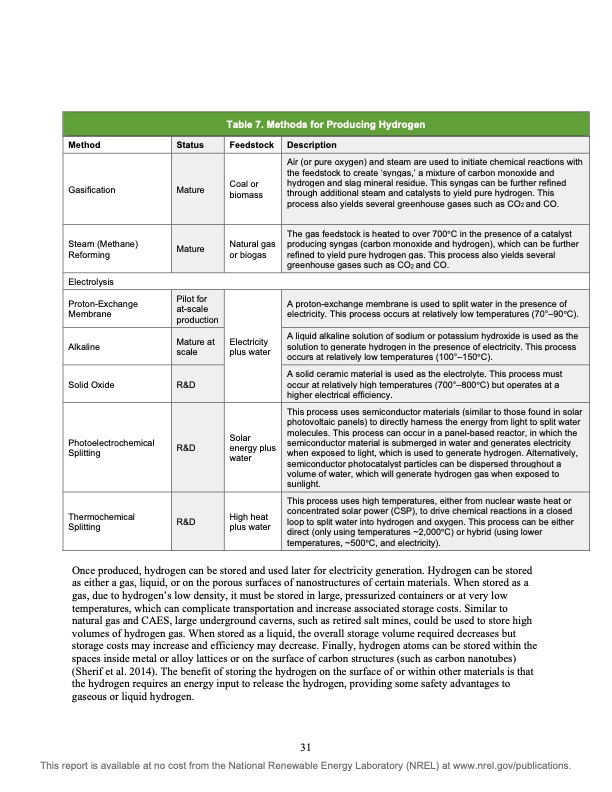

Method Table 7. Methods for Producing Hydrogen Status Feedstock Description Gasification Mature Coal or biomass Air (or pure oxygen) and steam are used to initiate chemical reactions with the feedstock to create ‘syngas,’ a mixture of carbon monoxide and hydrogen and slag mineral residue. This syngas can be further refined through additional steam and catalysts to yield pure hydrogen. This process also yields several greenhouse gases such as CO2 and CO. The gas feedstock is heated to over 700°C in the presence of a catalyst producing syngas (carbon monoxide and hydrogen), which can be further refined to yield pure hydrogen gas. This process also yields several greenhouse gases such as CO2 and CO. Steam (Methane) Reforming Mature Natural gas or biogas Electrolysis Proton-Exchange Membrane Alkaline ° Solid Oxide Mature at scale R&D A proton-exchange membrane is used to split water in the presence of electricity. This process occurs at relatively low temperatures (70°–90°C). Pilot for at-scale production Electricity plus water A liquid alkaline solution of sodium or potassium hydroxide is used as the solution to generate hydrogen in the presence of electricity. This process occurs at relatively low temperatures (100°–150 C). A solid ceramic material is used as the electrolyte. This process must occur at relatively high temperatures (700°–800°C) but operates at a higher electrical efficiency. Photoelectrochemical Splitting R&D Solar energy plus water This process uses semiconductor materials (similar to those found in solar photovoltaic panels) to directly harness the energy from light to split water molecules. This process can occur in a panel-based reactor, in which the semiconductor material is submerged in water and generates electricity when exposed to light, which is used to generate hydrogen. Alternatively, semiconductor photocatalyst particles can be dispersed throughout a volume of water, which will generate hydrogen gas when exposed to sunlight. Thermochemical Splitting R&D High heat plus water This process uses high temperatures, either from nuclear waste heat or concentrated solar power (CSP), to drive chemical reactions in a closed loop to split water into hydrogen and oxygen. This process can be either direct (only using temperatures ~2,000°C) or hybrid (using lower temperatures, ~500 C, and electricity). Once produced, hydrogen can be stored and used later for electricit°y generation. Hydrogen can be stored as either a gas, liquid, or on the porous surfaces of nanostructures of certain materials. When stored as a gas, due to hydrogen’s low density, it must be stored in large, pressurized containers or at very low temperatures, which can complicate transportation and increase associated storage costs. Similar to natural gas and CAES, large underground caverns, such as retired salt mines, could be used to store high volumes of hydrogen gas. When stored as a liquid, the overall storage volume required decreases but storage costs may increase and efficiency may decrease. Finally, hydrogen atoms can be stored within the spaces inside metal or alloy lattices or on the surface of carbon structures (such as carbon nanotubes) (Sherif et al. 2014). The benefit of storing the hydrogen on the surface of or within other materials is that the hydrogen requires an energy input to release the hydrogen, providing some safety advantages to gaseous or liquid hydrogen. 31 This report is available at no cost from the National Renewable Energy Laboratory (NREL) at www.nrel.gov/publications.PDF Image | USAID GRID-SCALE ENERGY STORAGE TECHNOLOGIES PRIMER

PDF Search Title:

USAID GRID-SCALE ENERGY STORAGE TECHNOLOGIES PRIMEROriginal File Name Searched:

76097.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Sand Battery Sand and Paraffin for TES Thermo Energy Storage More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |