PDF Publication Title:

Text from PDF Page: 043

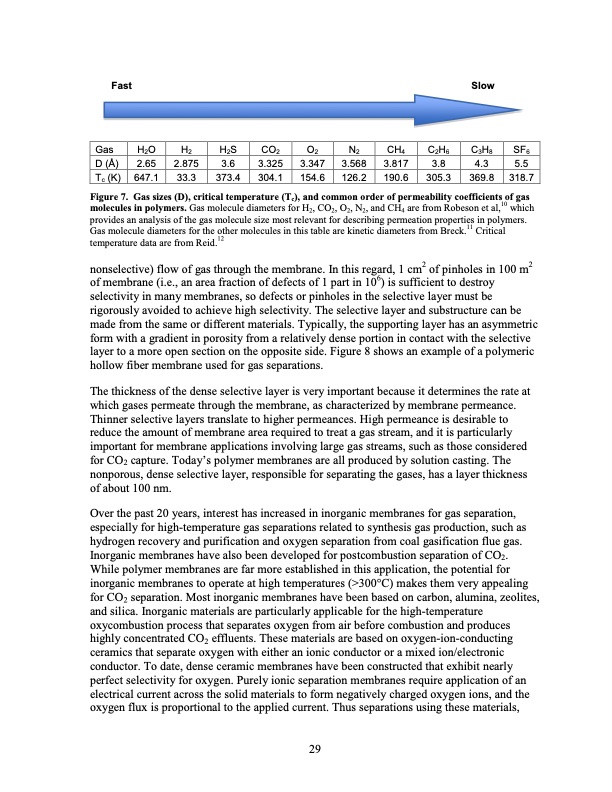

Fast Gas H2O H2 H2S D (Å) 2.65 2.875 3.6 Tc (K) 647.1 33.3 373.4 CO2 3.325 304.1 O2 3.347 154.6 N2 3.568 126.2 CH4 3.817 190.6 Slow C2H6 C3H8 SF6 3.8 4.3 5.5 305.3 369.8 318.7 Figure 7. Gas sizes (D), critical temperature (Tc), and common order of permeability coefficients of gas molecules in polymers. Gas molecule diameters for H2, CO2, O2, N2, and CH4 are from Robeson et al,10 which provides an analysis of the gas molecule size most relevant for describing permeation properties in polymers. Gas molecule diameters for the other molecules in this table are kinetic diameters from Breck.11 Critical temperature data are from Reid.12 nonselective) flow of gas through the membrane. In this regard, 1 cm2 of pinholes in 100 m2 of membrane (i.e., an area fraction of defects of 1 part in 106) is sufficient to destroy selectivity in many membranes, so defects or pinholes in the selective layer must be rigorously avoided to achieve high selectivity. The selective layer and substructure can be made from the same or different materials. Typically, the supporting layer has an asymmetric form with a gradient in porosity from a relatively dense portion in contact with the selective layer to a more open section on the opposite side. Figure 8 shows an example of a polymeric hollow fiber membrane used for gas separations. The thickness of the dense selective layer is very important because it determines the rate at which gases permeate through the membrane, as characterized by membrane permeance. Thinner selective layers translate to higher permeances. High permeance is desirable to reduce the amount of membrane area required to treat a gas stream, and it is particularly important for membrane applications involving large gas streams, such as those considered for CO2 capture. Today’s polymer membranes are all produced by solution casting. The nonporous, dense selective layer, responsible for separating the gases, has a layer thickness of about 100 nm. Over the past 20 years, interest has increased in inorganic membranes for gas separation, especially for high-temperature gas separations related to synthesis gas production, such as hydrogen recovery and purification and oxygen separation from coal gasification flue gas. Inorganic membranes have also been developed for postcombustion separation of CO2. While polymer membranes are far more established in this application, the potential for inorganic membranes to operate at high temperatures (>300°C) makes them very appealing for CO2 separation. Most inorganic membranes have been based on carbon, alumina, zeolites, and silica. Inorganic materials are particularly applicable for the high-temperature oxycombustion process that separates oxygen from air before combustion and produces highly concentrated CO2 effluents. These materials are based on oxygen-ion-conducting ceramics that separate oxygen with either an ionic conductor or a mixed ion/electronic conductor. To date, dense ceramic membranes have been constructed that exhibit nearly perfect selectivity for oxygen. Purely ionic separation membranes require application of an electrical current across the solid materials to form negatively charged oxygen ions, and the oxygen flux is proportional to the applied current. Thus separations using these materials, 29PDF Image | 2020 Carbon Capture

PDF Search Title:

2020 Carbon CaptureOriginal File Name Searched:

1291240.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |