PDF Publication Title:

Text from PDF Page: 041

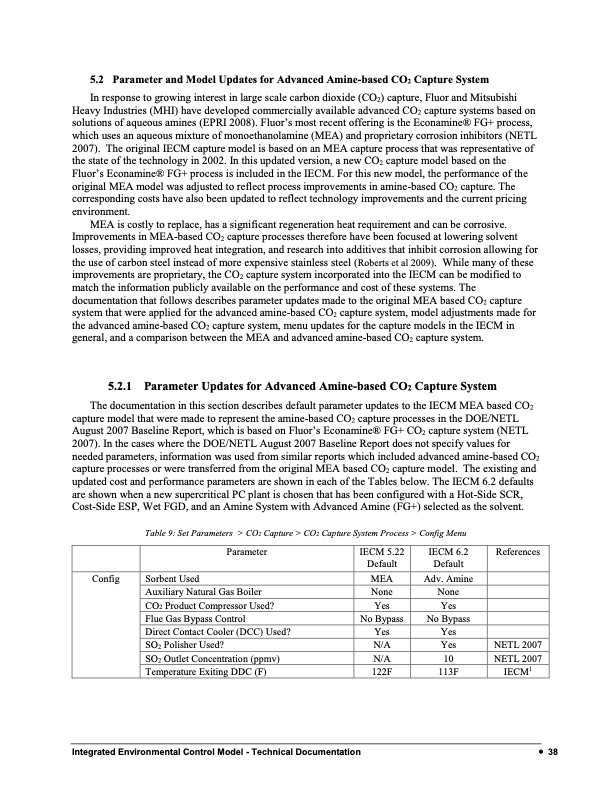

5.2 Parameter and Model Updates for Advanced Amine-based CO2 Capture System In response to growing interest in large scale carbon dioxide (CO2) capture, Fluor and Mitsubishi Heavy Industries (MHI) have developed commercially available advanced CO2 capture systems based on solutions of aqueous amines (EPRI 2008). Fluor’s most recent offering is the Econamine® FG+ process, which uses an aqueous mixture of monoethanolamine (MEA) and proprietary corrosion inhibitors (NETL 2007). The original IECM capture model is based on an MEA capture process that was representative of the state of the technology in 2002. In this updated version, a new CO2 capture model based on the Fluor’s Econamine® FG+ process is included in the IECM. For this new model, the performance of the original MEA model was adjusted to reflect process improvements in amine-based CO2 capture. The corresponding costs have also been updated to reflect technology improvements and the current pricing environment. MEA is costly to replace, has a significant regeneration heat requirement and can be corrosive. Improvements in MEA-based CO2 capture processes therefore have been focused at lowering solvent losses, providing improved heat integration, and research into additives that inhibit corrosion allowing for the use of carbon steel instead of more expensive stainless steel (Roberts et al 2009). While many of these improvements are proprietary, the CO2 capture system incorporated into the IECM can be modified to match the information publicly available on the performance and cost of these systems. The documentation that follows describes parameter updates made to the original MEA based CO2 capture system that were applied for the advanced amine-based CO2 capture system, model adjustments made for the advanced amine-based CO2 capture system, menu updates for the capture models in the IECM in general, and a comparison between the MEA and advanced amine-based CO2 capture system. 5.2.1 Parameter Updates for Advanced Amine-based CO2 Capture System The documentation in this section describes default parameter updates to the IECM MEA based CO2 capture model that were made to represent the amine-based CO2 capture processes in the DOE/NETL August 2007 Baseline Report, which is based on Fluor’s Econamine® FG+ CO2 capture system (NETL 2007). In the cases where the DOE/NETL August 2007 Baseline Report does not specify values for needed parameters, information was used from similar reports which included advanced amine-based CO2 capture processes or were transferred from the original MEA based CO2 capture model. The existing and updated cost and performance parameters are shown in each of the Tables below. The IECM 6.2 defaults are shown when a new supercritical PC plant is chosen that has been configured with a Hot-Side SCR, Cost-Side ESP, Wet FGD, and an Amine System with Advanced Amine (FG+) selected as the solvent. Table 9: Set Parameters > CO2 Capture > CO2 Capture System Process > Config Menu Config Parameter Sorbent Used Auxiliary Natural Gas Boiler CO2 Product Compressor Used? Flue Gas Bypass Control Direct Contact Cooler (DCC) Used? SO2 Polisher Used? SO2 Outlet Concentration (ppmv) Temperature Exiting DDC (F) IECM 5.22 Default MEA None Yes No Bypass Yes N/A N/A 122F IECM 6.2 Default Adv. Amine None Yes No Bypass Yes Yes 10 113F References NETL 2007 NETL 2007 IECM1 Integrated Environmental Control Model - Technical Documentation • 38PDF Image | Amine Based CO2 Capture

PDF Search Title:

Amine Based CO2 CaptureOriginal File Name Searched:

2019Jan_IECM-Amine-based-CO2-Capture.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |