PDF Publication Title:

Text from PDF Page: 123

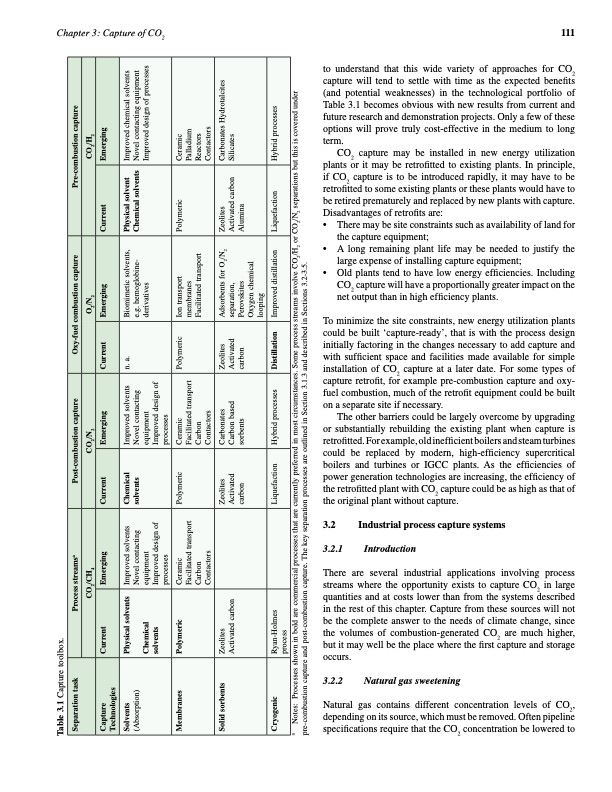

Chapter 3: Capture of CO2 111 to understand that this wide variety of approaches for CO2 capture will tend to settle with time as the expected benefits (and potential weaknesses) in the technological portfolio of Table 3.1 becomes obvious with new results from current and future research and demonstration projects. Only a few of these options will prove truly cost-effective in the medium to long term. CO2 capture may be installed in new energy utilization plants or it may be retrofitted to existing plants. In principle, if CO2 capture is to be introduced rapidly, it may have to be retrofitted to some existing plants or these plants would have to be retired prematurely and replaced by new plants with capture. Disadvantages of retrofits are: • There may be site constraints such as availability of land for the capture equipment; • A long remaining plant life may be needed to justify the large expense of installing capture equipment; • Old plants tend to have low energy efficiencies. Including CO2 capture will have a proportionally greater impact on the net output than in high efficiency plants. To minimize the site constraints, new energy utilization plants could be built ‘capture-ready’, that is with the process design initially factoring in the changes necessary to add capture and with sufficient space and facilities made available for simple installation of CO2 capture at a later date. For some types of capture retrofit, for example pre-combustion capture and oxy- fuel combustion, much of the retrofit equipment could be built on a separate site if necessary. The other barriers could be largely overcome by upgrading or substantially rebuilding the existing plant when capture is retrofitted. For example, old inefficient boilers and steam turbines could be replaced by modern, high-efficiency supercritical boilers and turbines or IGCC plants. As the efficiencies of power generation technologies are increasing, the efficiency of the retrofitted plant with CO2 capture could be as high as that of the original plant without capture. 3.2 industrial process capture systems 3.2.1 Introduction There are several industrial applications involving process streams where the opportunity exists to capture CO2 in large quantities and at costs lower than from the systems described in the rest of this chapter. Capture from these sources will not be the complete answer to the needs of climate change, since the volumes of combustion-generated CO2 are much higher, but it may well be the place where the first capture and storage occurs. 3.2.2 Natural gas sweetening Natural gas contains different concentration levels of CO2, depending on its source, which must be removed. Often pipeline specifications require that the CO2 concentration be lowered to table 3.1 Capture toolbox. Separation task Process streamsa CO2/CH4 Post-combustion capture Oxy-fuel combustion capture Pre-combustion capture CO2/H2 Capture technologies Current Emerging Current CO2/N2 Emerging Current O2/N2 Emerging Current Emerging Solvents Physical solvents Improved solvents Novel contacting equipment Improved design of processes Chemical solvents Improved solvents Novel contacting equipment Improved design of processes n. a. Biomimetic solvents, e.g. hemoglobine- derivatives Physical solvent Chemical solvents Improved chemical solvents Novel contacting equipment Improved design of processes (Absorption) Chemical solvents membranes Solid sorbents Polymeric Ceramic Facilitated transport Carbon Contactors Polymeric Ceramic Facilitated transport Carbon Contactors Polymeric Ion transport membranes Facilitated transport Polymeric Ceramic Palladium Reactors Contactors Cryogenic Ryan-Holmes Liquefaction Hybrid processes Distillation Improved distillation Liquefaction Hybrid processes Zeolites Activated carbon Zeolites Activated carbon Carbonates Carbon based sorbents Zeolites Activated carbon Adsorbents for O2/N2 separation, Perovskites Oxygen chemical looping Zeolites Activated carbon Alumina Carbonates Hydrotalcites Silicates process Notes: Processes shown in bold are commercial processes that are currently preferred in most circumstances. Some process streams involve CO2/H2 or CO2/N2 separations but this is covered under a pre-combustion capture and post-combustion capture. The key separation processes are outlined in Section 3.1.3 and described in Sections 3.2-3.5.PDF Image | CARBON DIOXIDE CAPTURE AND STORAGE

PDF Search Title:

CARBON DIOXIDE CAPTURE AND STORAGEOriginal File Name Searched:

srccs_wholereport.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |