PDF Publication Title:

Text from PDF Page: 144

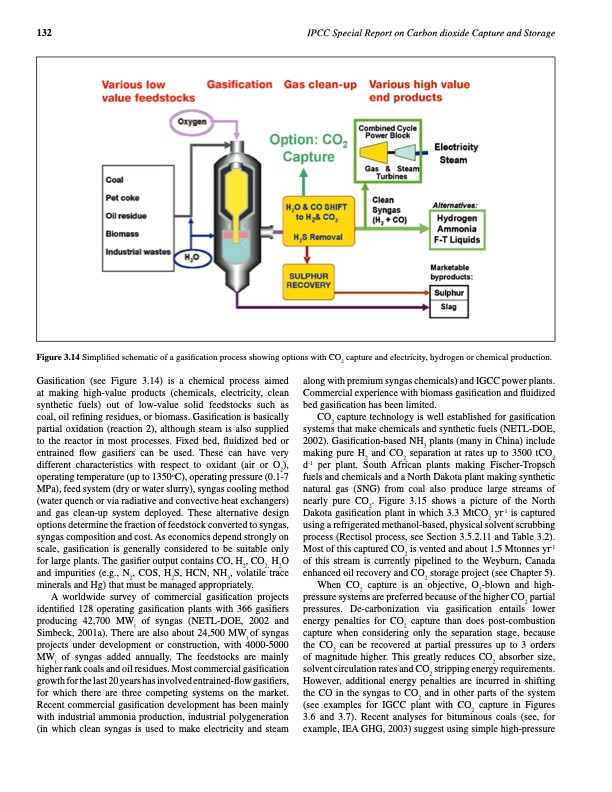

132 IPCC Special Report on Carbon dioxide Capture and Storage Figure 3.14 Simplified schematic of a gasification process showing options with CO2 capture and electricity, hydrogen or chemical production. Gasification (see Figure 3.14) is a chemical process aimed at making high-value products (chemicals, electricity, clean synthetic fuels) out of low-value solid feedstocks such as coal, oil refining residues, or biomass. Gasification is basically partial oxidation (reaction 2), although steam is also supplied to the reactor in most processes. Fixed bed, fluidized bed or entrained flow gasifiers can be used. These can have very different characteristics with respect to oxidant (air or O2), operating temperature (up to 1350oC), operating pressure (0.1-7 MPa), feed system (dry or water slurry), syngas cooling method (water quench or via radiative and convective heat exchangers) and gas clean-up system deployed. These alternative design options determine the fraction of feedstock converted to syngas, syngas composition and cost. As economics depend strongly on scale, gasification is generally considered to be suitable only for large plants. The gasifier output contains CO, H2, CO2, H2O and impurities (e.g., N2, COS, H2S, HCN, NH3, volatile trace minerals and Hg) that must be managed appropriately. along with premium syngas chemicals) and IGCC power plants. Commercial experience with biomass gasification and fluidized bed gasification has been limited. A worldwide survey of commercial gasification projects identified 128 operating gasification plants with 366 gasifiers producing 42,700 MWt of syngas (NETL-DOE, 2002 and Simbeck, 2001a). There are also about 24,500 MWt of syngas projects under development or construction, with 4000-5000 MWt of syngas added annually. The feedstocks are mainly higher rank coals and oil residues. Most commercial gasification growth for the last 20 years has involved entrained-flow gasifiers, for which there are three competing systems on the market. Recent commercial gasification development has been mainly with industrial ammonia production, industrial polygeneration (in which clean syngas is used to make electricity and steam When CO2 capture is an objective, O2-blown and high- pressure systems are preferred because of the higher CO2 partial pressures. De-carbonization via gasification entails lower energy penalties for CO2 capture than does post-combustion capture when considering only the separation stage, because the CO2 can be recovered at partial pressures up to 3 orders of magnitude higher. This greatly reduces CO2 absorber size, solvent circulation rates and CO2 stripping energy requirements. However, additional energy penalties are incurred in shifting the CO in the syngas to CO2 and in other parts of the system (see examples for IGCC plant with CO2 capture in Figures 3.6 and 3.7). Recent analyses for bituminous coals (see, for example, IEA GHG, 2003) suggest using simple high-pressure CO2 capture technology is well established for gasification systems that make chemicals and synthetic fuels (NETL-DOE, 2002). Gasification-based NH3 plants (many in China) include making pure H2 and CO2 separation at rates up to 3500 tCO2 d-1 per plant. South African plants making Fischer-Tropsch fuels and chemicals and a North Dakota plant making synthetic natural gas (SNG) from coal also produce large streams of nearly pure CO2. Figure 3.15 shows a picture of the North Dakota gasification plant in which 3.3 MtCO2 yr-1 is captured using a refrigerated methanol-based, physical solvent scrubbing process (Rectisol process, see Section 3.5.2.11 and Table 3.2). Most of this captured CO2 is vented and about 1.5 Mtonnes yr-1 of this stream is currently pipelined to the Weyburn, Canada enhanced oil recovery and CO2 storage project (see Chapter 5).PDF Image | CARBON DIOXIDE CAPTURE AND STORAGE

PDF Search Title:

CARBON DIOXIDE CAPTURE AND STORAGEOriginal File Name Searched:

srccs_wholereport.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |