PDF Publication Title:

Text from PDF Page: 204

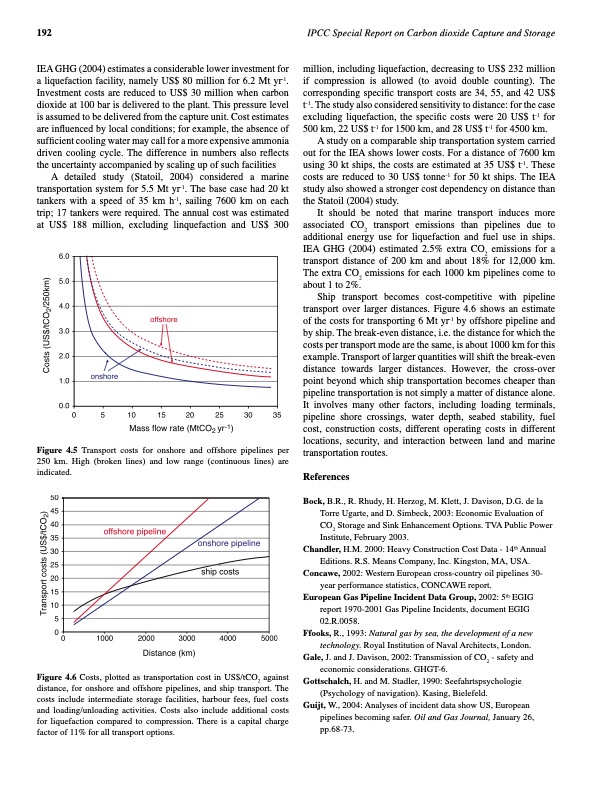

192 IPCC Special Report on Carbon dioxide Capture and Storage IEA GHG (2004) estimates a considerable lower investment for a liquefaction facility, namely US$ 80 million for 6.2 Mt yr-1. Investment costs are reduced to US$ 30 million when carbon dioxide at 100 bar is delivered to the plant. This pressure level is assumed to be delivered from the capture unit. Cost estimates are influenced by local conditions; for example, the absence of sufficient cooling water may call for a more expensive ammonia driven cooling cycle. The difference in numbers also reflects the uncertainty accompanied by scaling up of such facilities million, including liquefaction, decreasing to US$ 232 million if compression is allowed (to avoid double counting). The corresponding specific transport costs are 34, 55, and 42 US$ t-1. The study also considered sensitivity to distance: for the case excluding liquefaction, the specific costs were 20 US$ t-1 for 500 km, 22 US$ t-1 for 1500 km, and 28 US$ t-1 for 4500 km. A detailed study (Statoil, 2004) considered a marine transportation system for 5.5 Mt yr-1. The base case had 20 kt tankers with a speed of 35 km h-1, sailing 7600 km on each trip; 17 tankers were required. The annual cost was estimated at US$ 188 million, excluding linquefaction and US$ 300 A study on a comparable ship transportation system carried out for the IEA shows lower costs. For a distance of 7600 km using 30 kt ships, the costs are estimated at 35 US$ t-1. These costs are reduced to 30 US$ tonne-1 for 50 kt ships. The IEA study also showed a stronger cost dependency on distance than the Statoil (2004) study. It should be noted that marine transport induces more associated CO2 transport emissions than pipelines due to additional energy use for liquefaction and fuel use in ships. IEA GHG (2004) estimated 2.5% extra CO2 emissions for a transport distance of 200 km and about 18% for 12,000 km. The extra CO2 emissions for each 1000 km pipelines come to about 1 to 2%. Figure 4.5 Transport costs for onshore and offshore pipelines per 250 km. High (broken lines) and low range (continuous lines) are indicated. Ship transport becomes cost-competitive with pipeline transport over larger distances. Figure 4.6 shows an estimate of the costs for transporting 6 Mt yr-1 by offshore pipeline and by ship. The break-even distance, i.e. the distance for which the costs per transport mode are the same, is about 1000 km for this example. Transport of larger quantities will shift the break-even distance towards larger distances. However, the cross-over point beyond which ship transportation becomes cheaper than pipeline transportation is not simply a matter of distance alone. It involves many other factors, including loading terminals, pipeline shore crossings, water depth, seabed stability, fuel cost, construction costs, different operating costs in different locations, security, and interaction between land and marine transportation routes. Figure 4.6 Costs, plotted as transportation cost in US$/tCO2 against distance, for onshore and offshore pipelines, and ship transport. The costs include intermediate storage facilities, harbour fees, fuel costs and loading/unloading activities. Costs also include additional costs for liquefaction compared to compression. There is a capital charge factor of 11% for all transport options. References Bock, B.R., R. Rhudy, H. Herzog, M. Klett, J. Davison, D.G. de la Torre Ugarte, and D. Simbeck, 2003: Economic Evaluation of CO2 Storage and Sink Enhancement Options. TVA Public Power Institute, February 2003. Chandler, H.M. 2000: Heavy Construction Cost Data - 14th Annual Editions. R.S. Means Company, Inc. Kingston, MA, USA. Concawe, 2002: Western European cross-country oil pipelines 30- year performance statistics, CONCAWE report. European Gas Pipeline incident Data Group, 2002: 5th EGIG report 1970-2001 Gas Pipeline Incidents, document EGIG 02.R.0058. Ffooks, R., 1993: Natural gas by sea, the development of a new technology. Royal Institution of Naval Architects, London. Gale, J. and J. Davison, 2002: Transmission of CO2 - safety and economic considerations. GHGT-6. Gottschalch, H. and M. Stadler, 1990: Seefahrtspsychologie (Psychology of navigation). Kasing, Bielefeld. Guijt, W., 2004: Analyses of incident data show US, European pipelines becoming safer. Oil and Gas Journal, January 26, pp.68-73.PDF Image | CARBON DIOXIDE CAPTURE AND STORAGE

PDF Search Title:

CARBON DIOXIDE CAPTURE AND STORAGEOriginal File Name Searched:

srccs_wholereport.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |