PDF Publication Title:

Text from PDF Page: 024

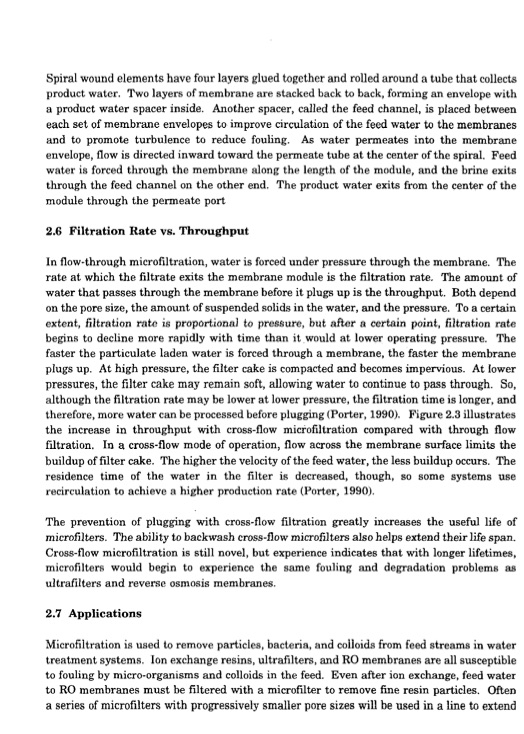

Spiral wound elements have four layers glued together and rolled around a tube that collects product water. Two layers of membrane are stacked back to back, forming an envelope with a product water spacer inside. Another spacer, called the feed channel, is placed between each set of membrane envelopes to improve circulation of the feed water to the membranes and to promote turbulence to reduce fouling. As water permeates into the membrane envelope, flow is directed inward toward the permeate tube at the center of the spiral. Feed water is forced through the membrane along the length of the module, and the brine exits through the feed channel on the other end. The product water exits from the center of the module through the permeate port 2.6 Filtration Rate vs. Throughput In flow-through microfiltration, water is forced under pressure through the membrane. The rate at which the filtrate exits the membrane module is the filtration rate. The amount of water that passes through the membrane before it plugs up is the throughput. Both depend on the pore size, the amount of suspended solids in the water, and the pressure. To a certain extent, filtration rate is proportional to pressure, but after a certain point, filtration rate begins to decline more rapidly with time than it ~would at lower operating pressure. The faster the particulate laden water is forced through a membrane, the faster the membrane plugs up. At high pressure, the filter cake is compacted and becomes impervious. At lower pressures, the filter cake may remain soft, allowing water to continue to pass through. So, although the filtration rate may be lower at lower pressure, the filtration time is longer, and therefore, more water can be processed before plugging (Porter, 1990). Figure 2.3 illustrates the increase in throughput with cross-flow microfiltration compared with through flow filtration. In a cross-flow mode of operation, flow across the membrane surface limits the buildup of filter cake. The higher the velocity of the feed water, the less buildup occurs. The residence time of the water in the filter is decreased, though, so some systems use recirculation to achieve a higher production rate (Porter, 1990). The prevention of plugging with cross-flow filtration greatly increases the useful life of microfilters. The ability to backwash cross-flow microfilters also helps extend their life span. Cross-flow microfiltration is still novel, but experience indicates that with longer lifetimes, microfilters would begin to experience the same fouling and degradation problems as ultrafilters and reverse osmosis membranes. 2.7 Applications Microfiltration is used to remove particles, bacteria, and colloids from feed streams in water treatment systems. Ion exchange resins, ultraiilters, and RO membranes are all susceptible to fouling by micro-organisms and colloids in the feed. Even after ion exchange, feed water to RO membranes must be filtered with a microfilter to remove fine resin particles. Often a series of microfilters with progressively smaller pore sizes will be used in a line to extendPDF Image | DESALTING AND WATER TREATMENT MEMBRANE

PDF Search Title:

DESALTING AND WATER TREATMENT MEMBRANEOriginal File Name Searched:

desalting-water-treatment-manual.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |