PDF Publication Title:

Text from PDF Page: 011

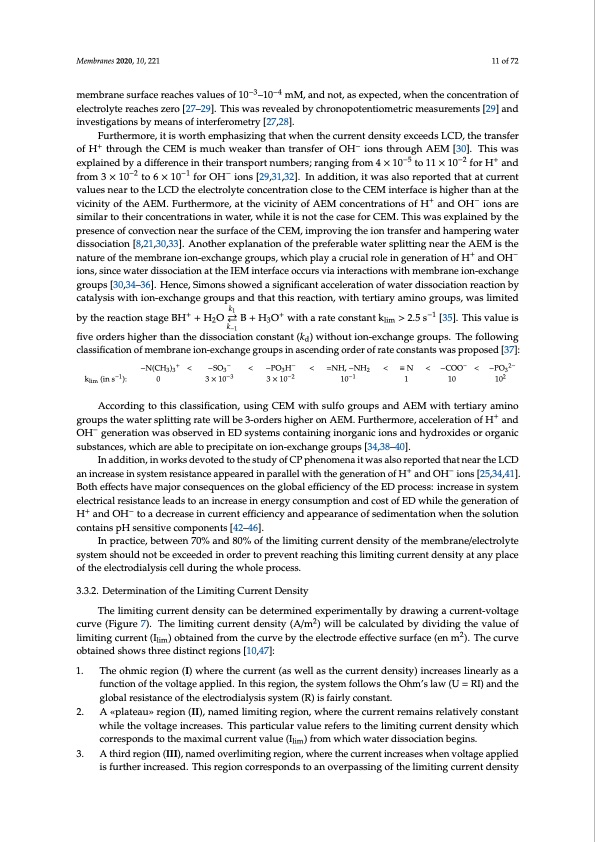

Membranes 2020, 10, 221 11 of 72 membrane surface reaches values of 10−3–10−4 mM, and not, as expected, when the concentration of electrolyte reaches zero [27–29]. This was revealed by chronopotentiometric measurements [29] and investigations by means of interferometry [27,28]. Furthermore, it is worth emphasizing that when the current density exceeds LCD, the transfer of H+ through the CEM is much weaker than transfer of OH− ions through AEM [30]. This was explained by a difference in their transport numbers; ranging from 4 × 10−5 to 11 × 10−2 for H+ and from 3 × 10−2 to 6 × 10−1 for OH− ions [29,31,32]. In addition, it was also reported that at current values near to the LCD the electrolyte concentration close to the CEM interface is higher than at the vicinity of the AEM. Furthermore, at the vicinity of AEM concentrations of H+ and OH− ions are similar to their concentrations in water, while it is not the case for CEM. This was explained by the presence of convection near the surface of the CEM, improving the ion transfer and hampering water dissociation [8,21,30,33]. Another explanation of the preferable water splitting near the AEM is the nature of the membrane ion-exchange groups, which play a crucial role in generation of H+ and OH− ions, since water dissociation at the IEM interface occurs via interactions with membrane ion-exchange groups [30,34–36]. Hence, Simons showed a significant acceleration of water dissociation reaction by catalysis with ion-exchange groups and that this reaction, with tertiary amino groups, was limited +k1+ −1 by the reaction stage BH + H2O B + H3O with a rate constant klim > 2.5 s [35]. This value is k−1 five orders higher than the dissociation constant (kd) without ion-exchange groups. The following classification of membrane ion-exchange groups in ascending order of rate constants was proposed [37]: −N(CH ) + < −SO − < −PO H− < =NH, −NH < ≡ N < −COO− < −PO 2− 333323 klim (in s−1): 0 3 × 10−3 3 × 10−2 10−1 1 10 102 According to this classification, using CEM with sulfo groups and AEM with tertiary amino groups the water splitting rate will be 3-orders higher on AEM. Furthermore, acceleration of H+ and OH− generation was observed in ED systems containing inorganic ions and hydroxides or organic substances, which are able to precipitate on ion-exchange groups [34,38–40]. In addition, in works devoted to the study of CP phenomena it was also reported that near the LCD an increase in system resistance appeared in parallel with the generation of H+ and OH− ions [25,34,41]. Both effects have major consequences on the global efficiency of the ED process: increase in system electrical resistance leads to an increase in energy consumption and cost of ED while the generation of H+ and OH− to a decrease in current efficiency and appearance of sedimentation when the solution contains pH sensitive components [42–46]. In practice, between 70% and 80% of the limiting current density of the membrane/electrolyte system should not be exceeded in order to prevent reaching this limiting current density at any place of the electrodialysis cell during the whole process. 3.3.2. Determination of the Limiting Current Density The limiting current density can be determined experimentally by drawing a current-voltage curve (Figure 7). The limiting current density (A/m2) will be calculated by dividing the value of limiting current (Ilim) obtained from the curve by the electrode effective surface (en m2). The curve obtained shows three distinct regions [10,47]: 1. The ohmic region (I) where the current (as well as the current density) increases linearly as a function of the voltage applied. In this region, the system follows the Ohm’s law (U = RI) and the global resistance of the electrodialysis system (R) is fairly constant. 2. A «plateau» region (II), named limiting region, where the current remains relatively constant while the voltage increases. This particular value refers to the limiting current density which corresponds to the maximal current value (Ilim) from which water dissociation begins. 3. A third region (III), named overlimiting region, where the current increases when voltage applied is further increased. This region corresponds to an overpassing of the limiting current densityPDF Image | Electrodialytic Processes

PDF Search Title:

Electrodialytic ProcessesOriginal File Name Searched:

membranes-10-00221.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |