PDF Publication Title:

Text from PDF Page: 033

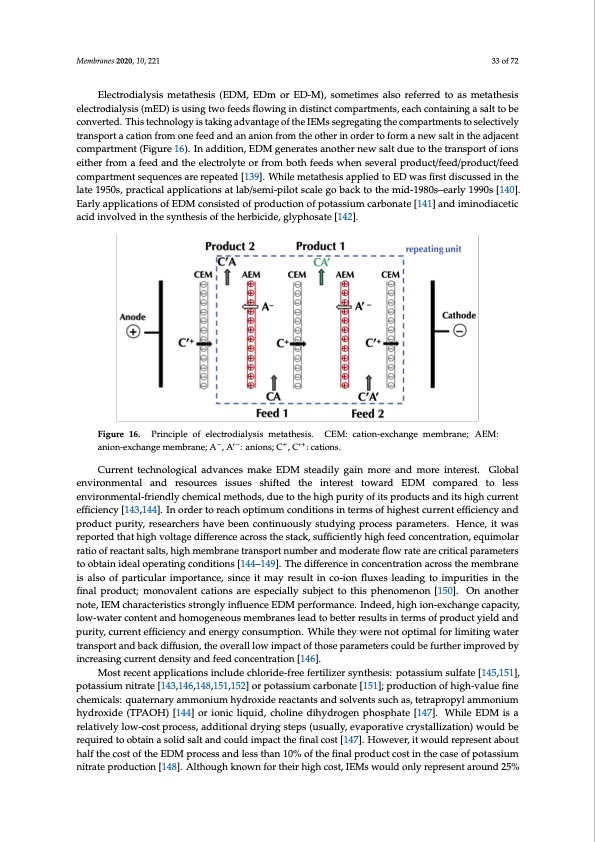

Membranes 2020, 10, 221 33 of 72 Electrodialysis metathesis (EDM, EDm or ED-M), sometimes also referred to as metathesis electrodialysis (mED) is using two feeds flowing in distinct compartments, each containing a salt to be converted. This technology is taking advantage of the IEMs segregating the compartments to selectively transport a cation from one feed and an anion from the other in order to form a new salt in the adjacent compartment (Figure 16). In addition, EDM generates another new salt due to the transport of ions either from a feed and the electrolyte or from both feeds when several product/feed/product/feed compartment sequences are repeated [139]. While metathesis applied to ED was first discussed in the late 1950s, practical applications at lab/semi-pilot scale go back to the mid-1980s–early 1990s [140]. Early applications of EDM consisted of production of potassium carbonate [141] and iminodiacetic acid involved in the synthesis of the herbicide, glyphosate [142]. Figure 16. Principle of electrodialysis metathesis. CEM: cation-exchange membrane; AEM: anion-exchange membrane; A−, A’−: anions; C+, C’+: cations. Current technological advances make EDM steadily gain more and more interest. Global environmental and resources issues shifted the interest toward EDM compared to less environmental-friendly chemical methods, due to the high purity of its products and its high current efficiency [143,144]. In order to reach optimum conditions in terms of highest current efficiency and product purity, researchers have been continuously studying process parameters. Hence, it was reported that high voltage difference across the stack, sufficiently high feed concentration, equimolar ratio of reactant salts, high membrane transport number and moderate flow rate are critical parameters to obtain ideal operating conditions [144–149]. The difference in concentration across the membrane is also of particular importance, since it may result in co-ion fluxes leading to impurities in the final product; monovalent cations are especially subject to this phenomenon [150]. On another note, IEM characteristics strongly influence EDM performance. Indeed, high ion-exchange capacity, low-water content and homogeneous membranes lead to better results in terms of product yield and purity, current efficiency and energy consumption. While they were not optimal for limiting water transport and back diffusion, the overall low impact of those parameters could be further improved by increasing current density and feed concentration [146]. Most recent applications include chloride-free fertilizer synthesis: potassium sulfate [145,151], potassium nitrate [143,146,148,151,152] or potassium carbonate [151]; production of high-value fine chemicals: quaternary ammonium hydroxide reactants and solvents such as, tetrapropyl ammonium hydroxide (TPAOH) [144] or ionic liquid, choline dihydrogen phosphate [147]. While EDM is a relatively low-cost process, additional drying steps (usually, evaporative crystallization) would be required to obtain a solid salt and could impact the final cost [147]. However, it would represent about half the cost of the EDM process and less than 10% of the final product cost in the case of potassium nitrate production [148]. Although known for their high cost, IEMs would only represent around 25%PDF Image | Electrodialytic Processes

PDF Search Title:

Electrodialytic ProcessesOriginal File Name Searched:

membranes-10-00221.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |