PDF Publication Title:

Text from PDF Page: 034

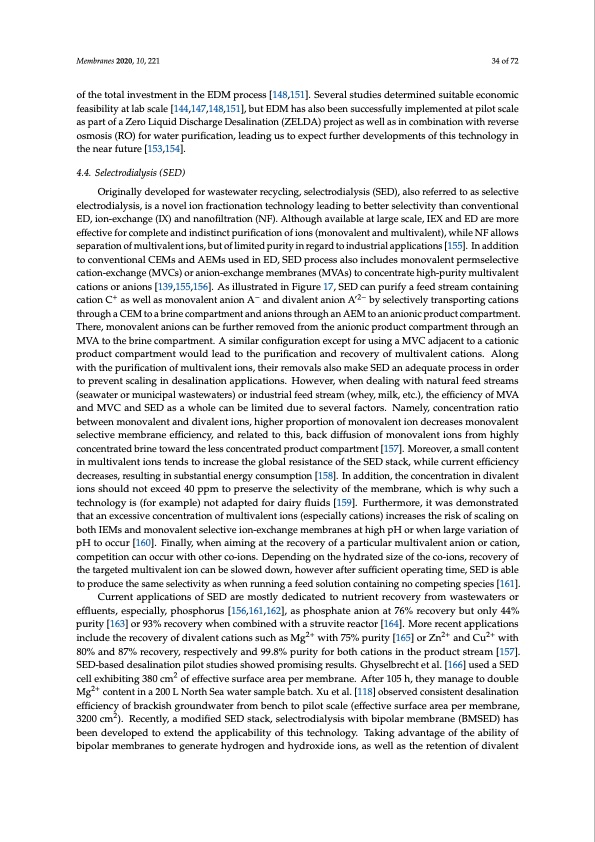

Membranes 2020, 10, 221 34 of 72 of the total investment in the EDM process [148,151]. Several studies determined suitable economic feasibility at lab scale [144,147,148,151], but EDM has also been successfully implemented at pilot scale as part of a Zero Liquid Discharge Desalination (ZELDA) project as well as in combination with reverse osmosis (RO) for water purification, leading us to expect further developments of this technology in the near future [153,154]. 4.4. Selectrodialysis (SED) Originally developed for wastewater recycling, selectrodialysis (SED), also referred to as selective electrodialysis, is a novel ion fractionation technology leading to better selectivity than conventional ED, ion-exchange (IX) and nanofiltration (NF). Although available at large scale, IEX and ED are more effective for complete and indistinct purification of ions (monovalent and multivalent), while NF allows separation of multivalent ions, but of limited purity in regard to industrial applications [155]. In addition to conventional CEMs and AEMs used in ED, SED process also includes monovalent permselective cation-exchange (MVCs) or anion-exchange membranes (MVAs) to concentrate high-purity multivalent cations or anions [139,155,156]. As illustrated in Figure 17, SED can purify a feed stream containing cation C+ as well as monovalent anion A− and divalent anion A’2− by selectively transporting cations through a CEM to a brine compartment and anions through an AEM to an anionic product compartment. There, monovalent anions can be further removed from the anionic product compartment through an MVA to the brine compartment. A similar configuration except for using a MVC adjacent to a cationic product compartment would lead to the purification and recovery of multivalent cations. Along with the purification of multivalent ions, their removals also make SED an adequate process in order to prevent scaling in desalination applications. However, when dealing with natural feed streams (seawater or municipal wastewaters) or industrial feed stream (whey, milk, etc.), the efficiency of MVA and MVC and SED as a whole can be limited due to several factors. Namely, concentration ratio between monovalent and divalent ions, higher proportion of monovalent ion decreases monovalent selective membrane efficiency, and related to this, back diffusion of monovalent ions from highly concentrated brine toward the less concentrated product compartment [157]. Moreover, a small content in multivalent ions tends to increase the global resistance of the SED stack, while current efficiency decreases, resulting in substantial energy consumption [158]. In addition, the concentration in divalent ions should not exceed 40 ppm to preserve the selectivity of the membrane, which is why such a technology is (for example) not adapted for dairy fluids [159]. Furthermore, it was demonstrated that an excessive concentration of multivalent ions (especially cations) increases the risk of scaling on both IEMs and monovalent selective ion-exchange membranes at high pH or when large variation of pH to occur [160]. Finally, when aiming at the recovery of a particular multivalent anion or cation, competition can occur with other co-ions. Depending on the hydrated size of the co-ions, recovery of the targeted multivalent ion can be slowed down, however after sufficient operating time, SED is able to produce the same selectivity as when running a feed solution containing no competing species [161]. Current applications of SED are mostly dedicated to nutrient recovery from wastewaters or effluents, especially, phosphorus [156,161,162], as phosphate anion at 76% recovery but only 44% purity [163] or 93% recovery when combined with a struvite reactor [164]. More recent applications include the recovery of divalent cations such as Mg2+ with 75% purity [165] or Zn2+ and Cu2+ with 80% and 87% recovery, respectively and 99.8% purity for both cations in the product stream [157]. SED-based desalination pilot studies showed promising results. Ghyselbrecht et al. [166] used a SED cell exhibiting 380 cm2 of effective surface area per membrane. After 105 h, they manage to double Mg2+ content in a 200 L North Sea water sample batch. Xu et al. [118] observed consistent desalination efficiency of brackish groundwater from bench to pilot scale (effective surface area per membrane, 3200 cm2). Recently, a modified SED stack, selectrodialysis with bipolar membrane (BMSED) has been developed to extend the applicability of this technology. Taking advantage of the ability of bipolar membranes to generate hydrogen and hydroxide ions, as well as the retention of divalentPDF Image | Electrodialytic Processes

PDF Search Title:

Electrodialytic ProcessesOriginal File Name Searched:

membranes-10-00221.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |