PDF Publication Title:

Text from PDF Page: 036

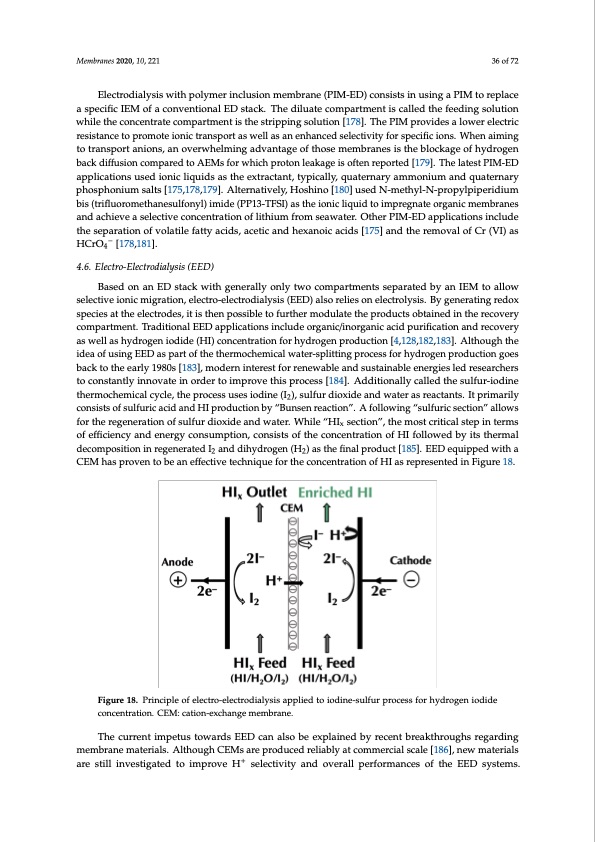

Membranes 2020, 10, 221 36 of 72 Electrodialysis with polymer inclusion membrane (PIM-ED) consists in using a PIM to replace a specific IEM of a conventional ED stack. The diluate compartment is called the feeding solution while the concentrate compartment is the stripping solution [178]. The PIM provides a lower electric resistance to promote ionic transport as well as an enhanced selectivity for specific ions. When aiming to transport anions, an overwhelming advantage of those membranes is the blockage of hydrogen back diffusion compared to AEMs for which proton leakage is often reported [179]. The latest PIM-ED applications used ionic liquids as the extractant, typically, quaternary ammonium and quaternary phosphonium salts [175,178,179]. Alternatively, Hoshino [180] used N-methyl-N-propylpiperidium bis (trifluoromethanesulfonyl) imide (PP13-TFSI) as the ionic liquid to impregnate organic membranes and achieve a selective concentration of lithium from seawater. Other PIM-ED applications include the separation of volatile fatty acids, acetic and hexanoic acids [175] and the removal of Cr (VI) as HCrO − [178,181]. 4 4.6. Electro-Electrodialysis (EED) Based on an ED stack with generally only two compartments separated by an IEM to allow selective ionic migration, electro-electrodialysis (EED) also relies on electrolysis. By generating redox species at the electrodes, it is then possible to further modulate the products obtained in the recovery compartment. Traditional EED applications include organic/inorganic acid purification and recovery as well as hydrogen iodide (HI) concentration for hydrogen production [4,128,182,183]. Although the idea of using EED as part of the thermochemical water-splitting process for hydrogen production goes back to the early 1980s [183], modern interest for renewable and sustainable energies led researchers to constantly innovate in order to improve this process [184]. Additionally called the sulfur-iodine thermochemical cycle, the process uses iodine (I2), sulfur dioxide and water as reactants. It primarily consists of sulfuric acid and HI production by “Bunsen reaction”. A following “sulfuric section” allows for the regeneration of sulfur dioxide and water. While “HIx section”, the most critical step in terms of efficiency and energy consumption, consists of the concentration of HI followed by its thermal decomposition in regenerated I2 and dihydrogen (H2) as the final product [185]. EED equipped with a CEM has proven to be an effective technique for the concentration of HI as represented in Figure 18. Figure 18. Principle of electro-electrodialysis applied to iodine-sulfur process for hydrogen iodide concentration. CEM: cation-exchange membrane. The current impetus towards EED can also be explained by recent breakthroughs regarding membrane materials. Although CEMs are produced reliably at commercial scale [186], new materials are still investigated to improve H+ selectivity and overall performances of the EED systems.PDF Image | Electrodialytic Processes

PDF Search Title:

Electrodialytic ProcessesOriginal File Name Searched:

membranes-10-00221.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |