PDF Publication Title:

Text from PDF Page: 049

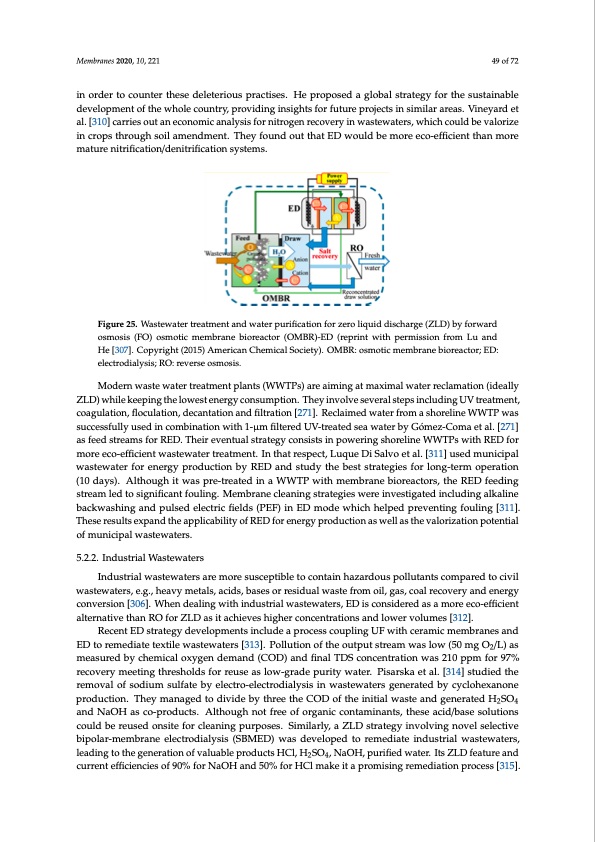

soluble nutrients in irrigation waters [298]). Using a fertilizer (diammonium phosphate) solution as the draw leads to efficient water recovery (96.6% with 0.8 kWh/m3 power consumption). Moreover, at the end of the process the low NaCl content of the fertilizer-containing draw promotes its potential at larger scale for fertigation, therefore reducing liquid effluents to be disposed. In areas prone to fMremshbrawneast2e0r2d0,e1f0i,c2i2e1ncy like Egypt, untreated drainage wastewaters have been mixed directly wi4t9hotfh7e2 Nile river water for irrigation. While it reduces the waste of potable water, the poor water quality is detrimental to crops. Wastewater treatment using electrodialytic technologies has been investigated in order to counter these deleterious practises. He proposed a global strategy for the sustainable by Abou-Shady [309] in order to counter these deleterious practises. He proposed a global strategy development of the whole country, providing insights for future projects in similar areas. Vineyard et for the sustainable development of the whole country, providing insights for future projects in similar al. [310] carries out an economic analysis for nitrogen recovery in wastewaters, which could be valorize areas. Vineyard et al. [310] carries out an economic analysis for nitrogen recovery in wastewaters, in crops through soil amendment. They found out that ED would be more eco-efficient than more which could be valorize in crops through soil amendment. They found out that ED would be more mature nitrification/denitrification systems. eco-efficient than more mature nitrification/denitrification systems. Figure 25. Wastewater treatment and water purification for zero liquid discharge (ZLD) by forward Figure 25. Wastewater treatment and water purification for zero liquid discharge (ZLD) by forward osmosis (FO) osmotic membrane bioreactor (OMBR)-ED (reprint with permission from Lu and He osmosis (FO) osmotic membrane bioreactor (OMBR)-ED (reprint with permission from Lu and [307]. Copyright (2015) American Chemical Society). OMBR: osmotic membrane bioreactor; ED: He [307]. Copyright (2015) American Chemical Society). OMBR: osmotic membrane bioreactor; ED: electrodialysis; RO: reverse osmosis. electrodialysis; RO: reverse osmosis. Modern waste water treatment plants (WWTPs) are aiming at maximal water reclamation Modern waste water treatment plants (WWTPs) are aiming at maximal water reclamation (ideally (ideally ZLD) while keeping the lowest energy consumption. They involve several steps including ZLD) while keeping the lowest energy consumption. They involve several steps including UV treatment, UV treatment, coagulation, floculation, decantation and filtration [271]. Reclaimed water from a coagulation, floculation, decantation and filtration [271]. Reclaimed water from a shoreline WWTP was shoreline WWTP was successfully used in combination with 1-μm filtered UV-treated sea water by successfully used in combination with 1-μm filtered UV-treated sea water by Gómez-Coma et al. [271] Gómez-Coma et al. [271] as feed streams for RED. Their eventual strategy consists in powering as feed streams for RED. Their eventual strategy consists in powering shoreline WWTPs with RED for shoreline WWTPs with RED for more eco-efficient wastewater treatment. In that respect, Luque Di more eco-efficient wastewater treatment. In that respect, Luque Di Salvo et al. [311] used municipal Salvo et al. [311] used municipal wastewater for energy production by RED and study the best wastewater for energy production by RED and study the best strategies for long-term operation strategies for long-term operation (10 days). Although it was pre-treated in a WWTP with membrane (10 days). Although it was pre-treated in a WWTP with membrane bioreactors, the RED feeding bioreactors, the RED feeding stream led to significant fouling. Membrane cleaning strategies were stream led to significant fouling. Membrane cleaning strategies were investigated including alkaline investigated including alkaline backwashing and pulsed electric fields (PEF) in ED mode which backwashing and pulsed electric fields (PEF) in ED mode which helped preventing fouling [311]. helped preventing fouling [311]. These results expand the applicability of RED for energy production These results expand the applicability of RED for energy production as well as the valorization potential as well as the valorization potential of municipal wastewaters. of municipal wastewaters. 5.2.2. Industrial Wastewaters Industrial wastewaters are more susceptible to contain hazardous pollutants compared to civil wastewaters, e.g., heavy metals, acids, bases or residual waste from oil, gas, coal recovery and energy conversion [306]. When dealing with industrial wastewaters, ED is considered as a more eco-efficient alternative than RO for ZLD as it achieves higher concentrations and lower volumes [312]. Recent ED strategy developments include a process coupling UF with ceramic membranes and ED to remediate textile wastewaters [313]. Pollution of the output stream was low (50 mg O2/L) as measured by chemical oxygen demand (COD) and final TDS concentration was 210 ppm for 97% recovery meeting thresholds for reuse as low-grade purity water. Pisarska et al. [314] studied the removal of sodium sulfate by electro-electrodialysis in wastewaters generated by cyclohexanone production. They managed to divide by three the COD of the initial waste and generated H2SO4 and NaOH as co-products. Although not free of organic contaminants, these acid/base solutions could be reused onsite for cleaning purposes. Similarly, a ZLD strategy involving novel selective bipolar-membrane electrodialysis (SBMED) was developed to remediate industrial wastewaters, leading to the generation of valuable products HCl, H2SO4, NaOH, purified water. Its ZLD feature and current efficiencies of 90% for NaOH and 50% for HCl make it a promising remediation process [315].PDF Image | Electrodialytic Processes

PDF Search Title:

Electrodialytic ProcessesOriginal File Name Searched:

membranes-10-00221.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |